Debris flow prevention and treatment system

A mud-rock flow and drainage system technology, applied in waterway systems, drainage structures, water supply devices, etc., can solve problems such as blockage of cover plates with holes by stones, improve drainage efficiency, avoid blockage of cover plates, and reduce destructive power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

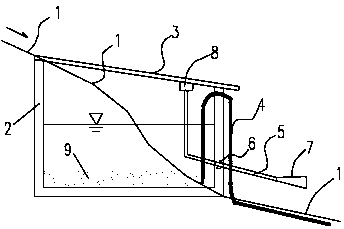

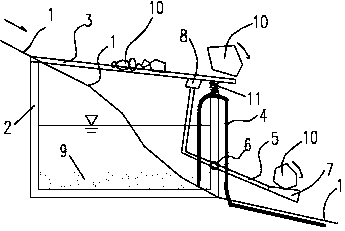

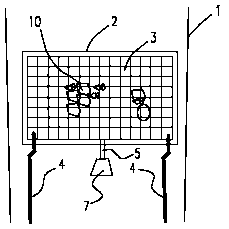

[0038] like Figure 1-3 As shown, this specific embodiment provides a debris flow prevention and control system, including a drainage system and a vibration system. The drainage system includes a sump 2, a cover plate with holes 3, and a drainage pipe 4. The sump 2 is excavated in the debris flow channel 1 A perforated cover plate 3 is set above the sump 2, one end of the drain pipe 4 extends into the sump 2, the other end of the drain pipe 3 is set in the safe area of the debris flow channel 1 outside the sump 2, and the vibration system includes a rotating rod 5. Fixed shaft 6, pedal 7, support block 8, spring 11, fixed shaft 6 is fixed on the front wall of sump 2, rotating rod 5 is connected with fixed shaft 6, one end of rotating rod 5 is connected with supporting block 8, and supporting block 8 is connected with The cover plate with holes 3 is in contact, the other end of the rotating rod 5 is connected to the pedal 7, the rear end of the cover plate 3 with holes is hin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com