Ducted positive crankcase ventilation plenum

A crankcase, ducted technology, applied in the direction of crankcase ventilation, fuel air intake, combustion air/combustion-air treatment, etc., can solve the problem of oil separator efficiency reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

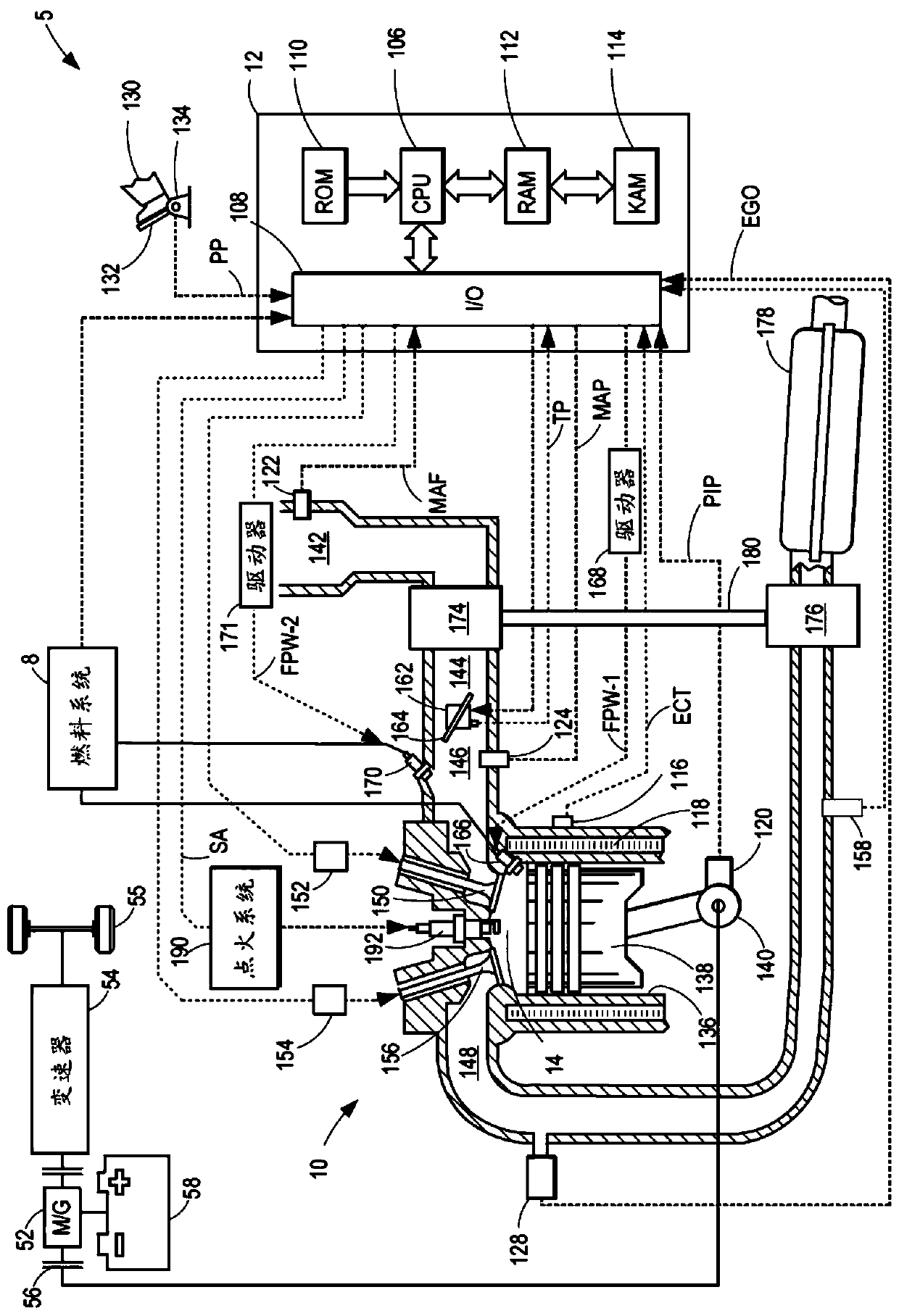

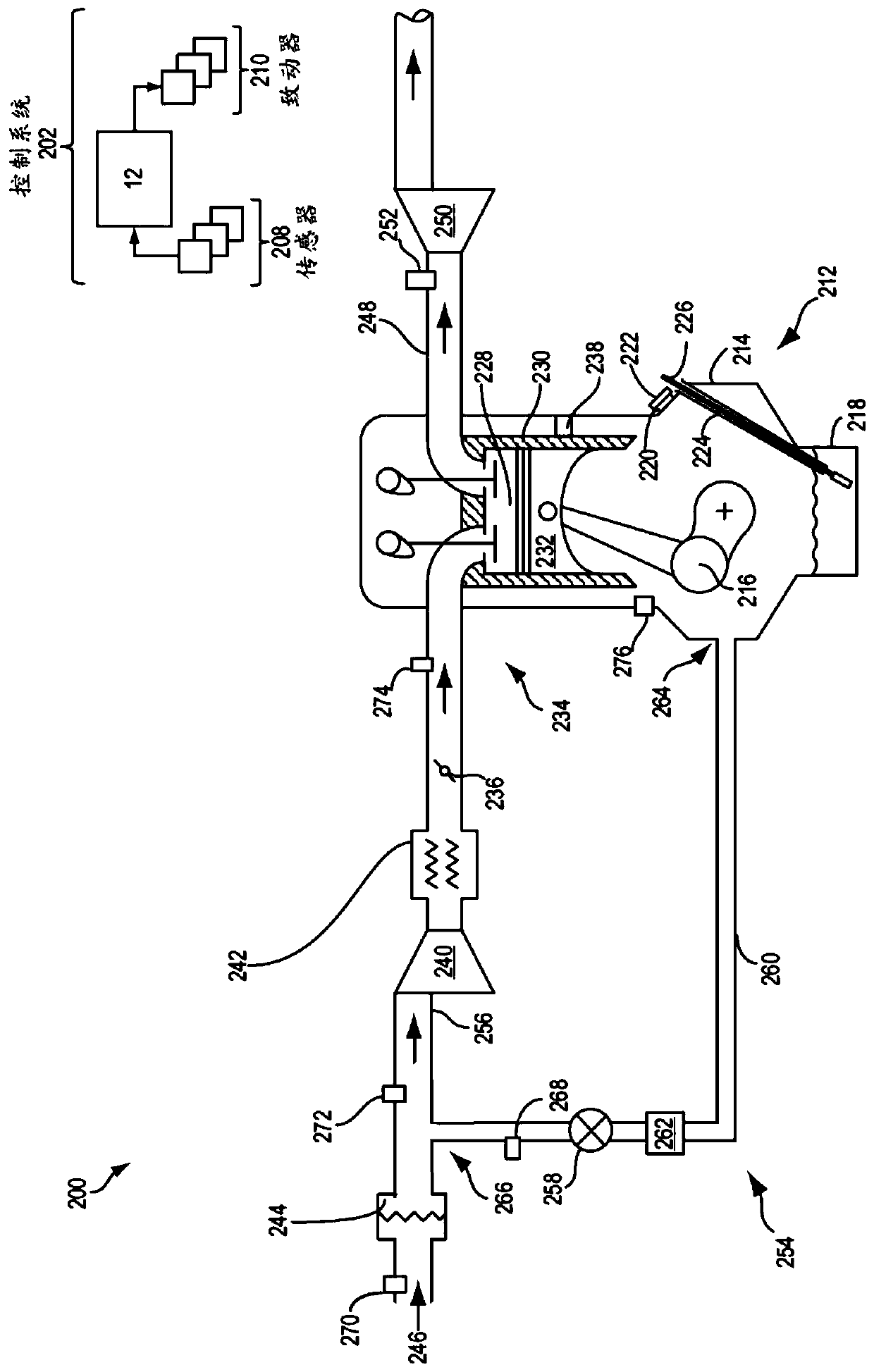

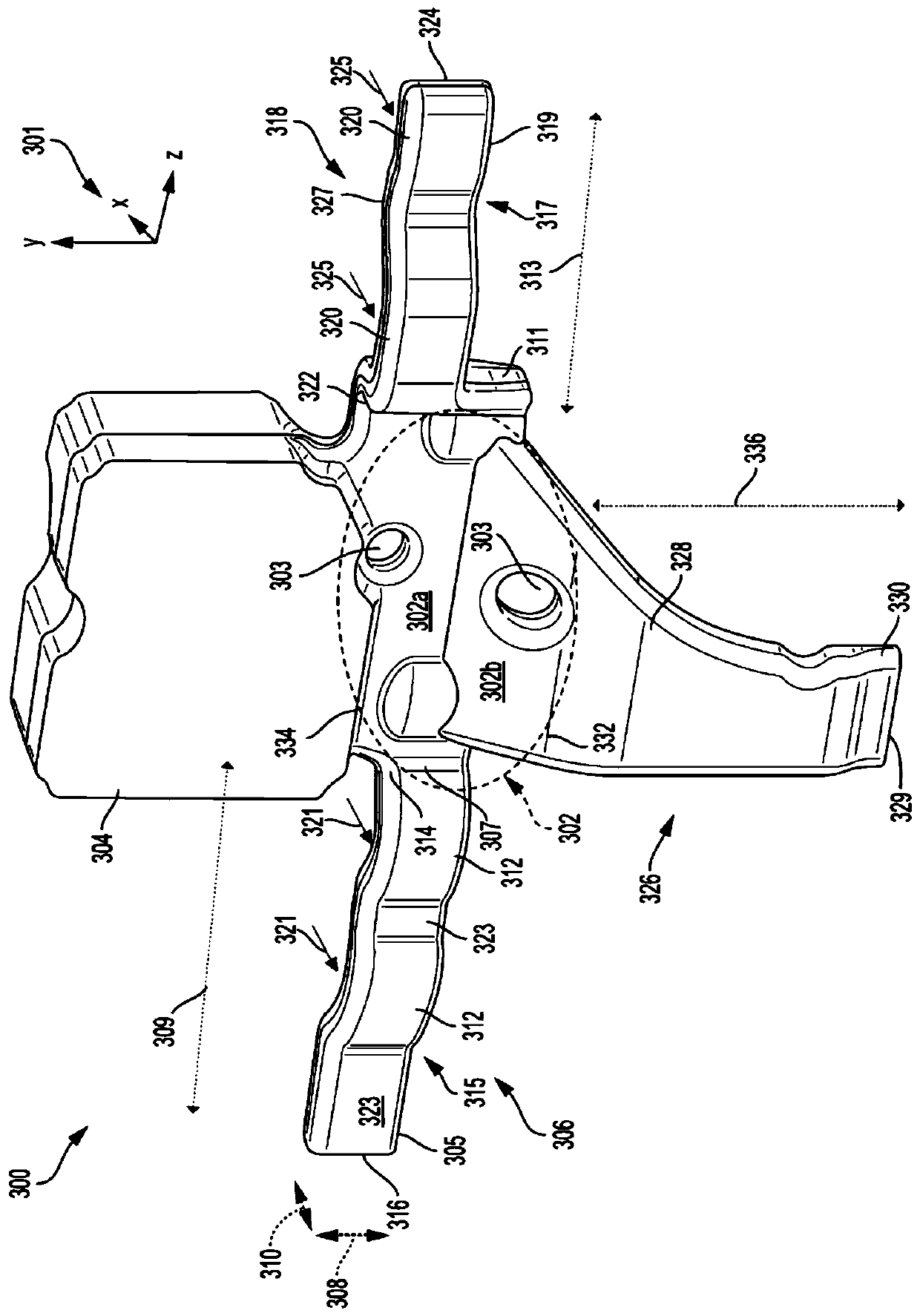

[0019] The following description relates to systems and methods for a PCV system. In an engine system, the crankcase can build up pressure due to blow-by of combustion gases. A PCV system may be installed in the engine, coupled to the exhaust system for recirculation of blow-by gases to the engine intake system. exist figure 1 A schematic diagram of an example of an engine system adapted with a PCV system is shown in . exist figure 2 An example of an engine is illustrated in , which depicts a single combustion chamber of the engine and the arrangement of the PCV system relative to the combustion chamber. The PCV system may include a ducted plenum having ducts coupled to a cylinder compartment of the engine. Blow-by gases from the cylinder compartment may be collected in a ducted plenum before passing through an oil separator arranged upstream of a PCV valve that controls the flow of gas from the crankcase to the engine intake system. exist image 3 An example of a ducte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com