A test method for oil film thickness of axial rubber-plastic seal

A test method and film thickness technology, which is applied in the fields of oil film thickness measurement, rubber and plastic seal scientific research, and working condition monitoring, can solve the problems of non-diffusion of heat, testing, and affecting the life of seals, etc., to achieve reliable measurement circuits, low prices, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

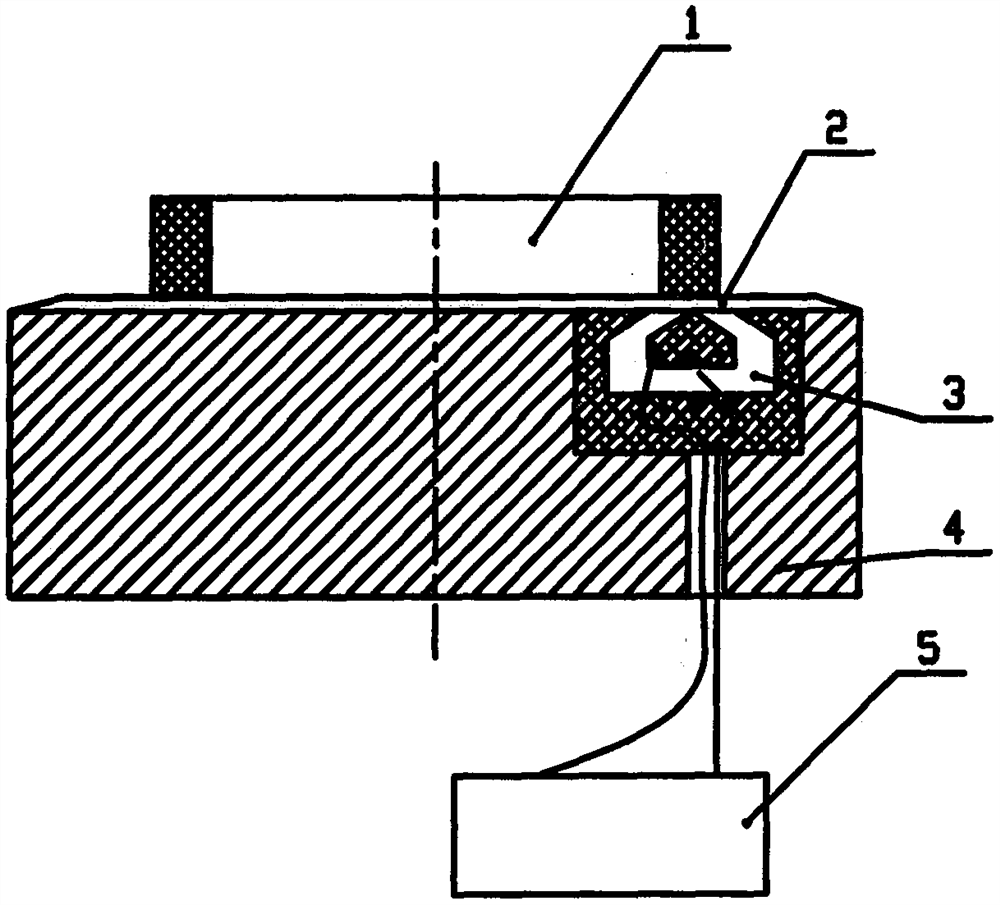

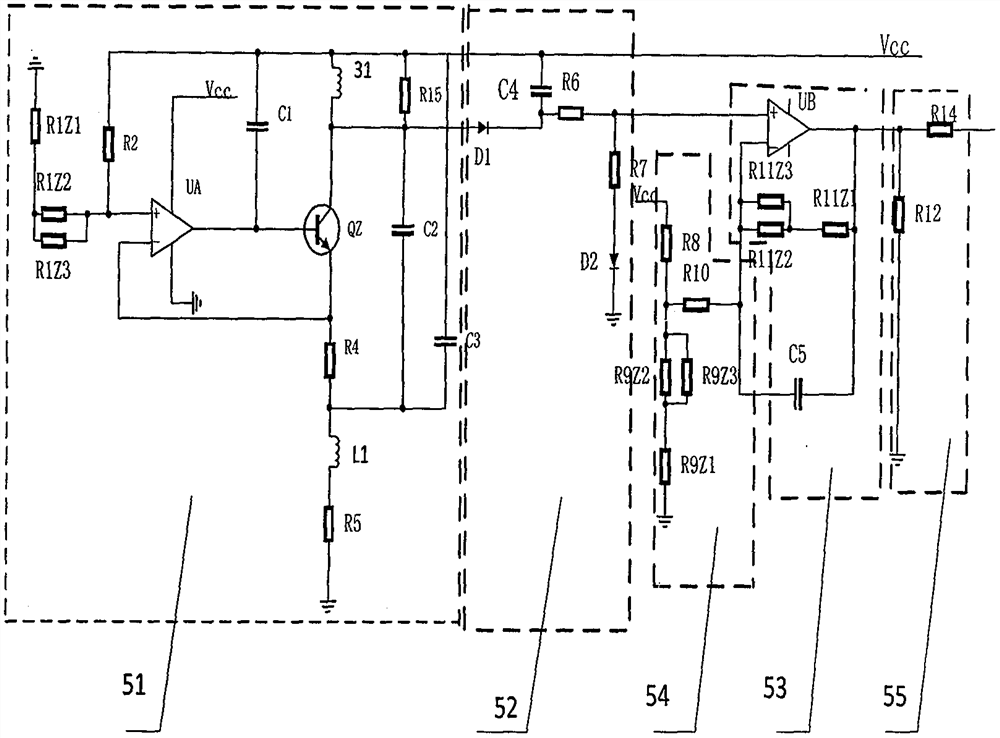

[0010] Such as figure 1 As shown, it is composed of axial rubber and plastic seal 1, magnetic fluid 2, sensor head 3, analog seal pair 4 and signal extraction processing circuit 5, and the space between axial rubber and plastic seal 1 and sensor head 3 is filled with magnetic fluid 2, The sensing head 3 is installed in the analog sealing pair 4, and the two wires of the sensing head 3 are respectively connected with the triode QZ collector of the signal extraction processing circuit 5 and the power supply, and the signal extraction processing circuit 5 is composed. The test method includes the following steps:

[0011] 1) Prepare a special lubricating oil-magnetic fluid 2, the magnetic powder added is NdFeB magnetic powder, the particle size is nanometer, and it is stirred evenly.

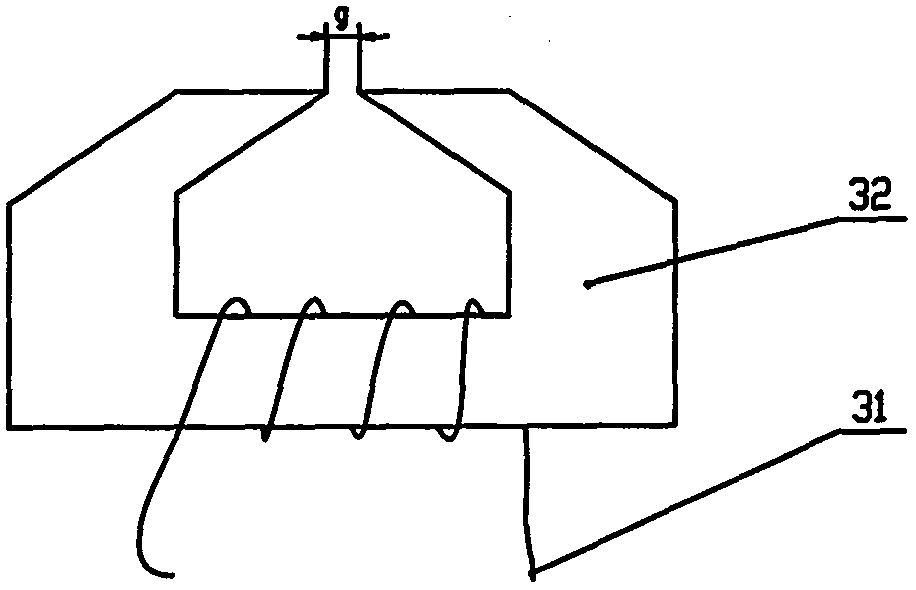

[0012] 2) Groove the analog seal pair 4, install the sensor head 3 in the groove of the analog seal pair 4, pay attention to the parallelism between the upper surface of the sensor head 3 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com