Free ground film, circuit board and preparation method of free ground film

A circuit board and printed circuit board technology, applied in the electronic field, can solve problems such as inability to interfere with charge derivation, connection failure between free grounding film and electromagnetic shielding film, and influence on signal transmission of circuit boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

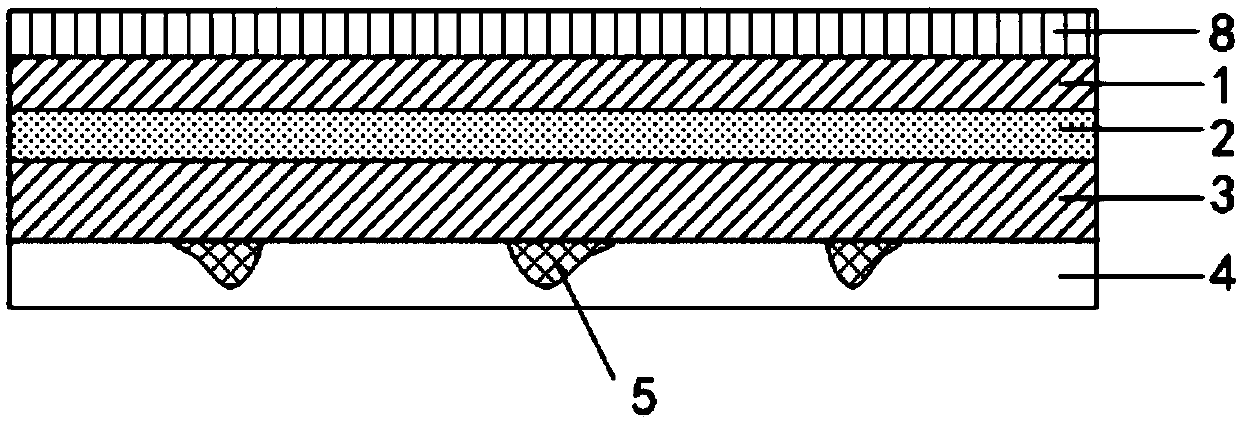

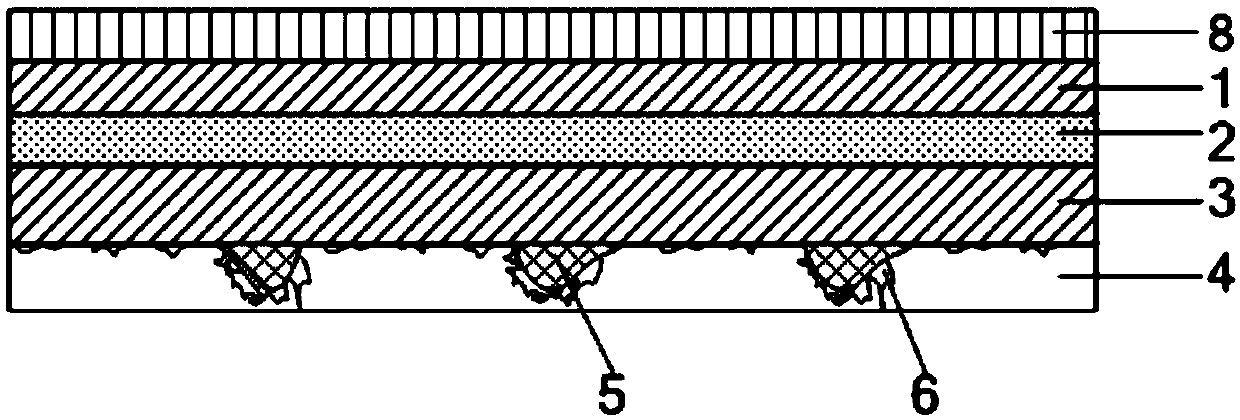

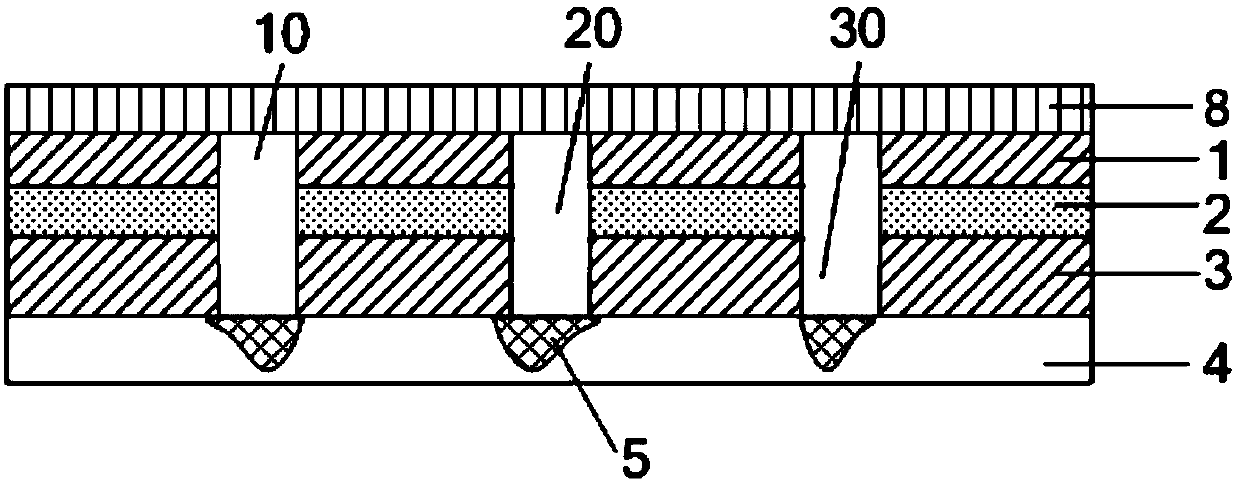

[0066] See figure 1 , the embodiment of the present invention provides a free grounding film, which includes a first conductor layer 1, a conductive adhesive layer 2, a second conductor layer 3 and an adhesive film layer 4 which are sequentially stacked; the second conductor layer 3 is close to the Conductive protrusions 5 are provided on one side of the adhesive film layer 4;

[0067] see Figure 9 , when the free grounding film is used for the grounding of the printed circuit board, an electromagnetic shielding film 9 is provided on the printed circuit board 11, and the electromagnetic shielding film 9 includes a shielding layer 91 and an insulating layer 90 stacked. The free grounding film is pressed together with the electromagnetic shielding film 9 through the adhesive film layer 4, and the conductive protrusion 5 pierces through the adhesive film layer 4 and the insulating layer 90 and is electrically connected with the shielding layer 91 . Wherein, the material of th...

Embodiment 2

[0104] see Figure 4, the embodiment of the present invention provides another free grounding film, which includes a first conductor layer 1, a conductive adhesive layer 2, a second conductor layer 3, a third conductor layer 7 and an adhesive film layer 4; the first conductor layer 1. The conductive adhesive layer 2 and the second conductive layer 3 are sequentially stacked; the second conductive layer 3 is provided with conductive protrusions 5 on the side away from the conductive adhesive layer 2; the third The conductor layer 7 is covered on the one side of the second conductor layer 3, and the position of the third conductor layer 7 covering the conductive protrusion 5 forms a raised portion 70 (the raised portion 70 and the The relationship between the conductive bumps 5 can be one-to-one correspondence, one-to-many correspondence, or many-to-one correspondence, etc. When the relationship between the raised portion 70 and the conductive bumps 5 is a one-to-one corresponde...

Embodiment 3

[0120] see Figure 9 and Figure 10 , the embodiment of the present invention provides a circuit board, including a printed circuit board 11 and an electromagnetic shielding film 9 provided on the printed circuit board 11 .

[0121] see Figure 9 , the circuit board also includes the free grounding film of any solution in the first embodiment; the electromagnetic shielding film 9 includes a shielding layer 91 and an insulating layer 90 stacked, and the free grounding film passes through the adhesive film The layer 4 is pressed against the electromagnetic shielding film 9 , and the conductive protrusion 5 pierces through the adhesive film layer 4 and the insulating layer 90 and is electrically connected to the shielding layer 91 .

[0122] or, see Figure 10 , the circuit board also includes the free grounding film of any solution in the second embodiment; the electromagnetic shielding film 9 includes a shielding layer 91 and an insulating layer 90 stacked, and the free grou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com