Pumping and injecting integrated device and liquid pumping and injecting method of novel water cooling system

A water-cooling system and an integrated technology, applied in the field of converters, can solve problems such as low work efficiency, inability to meet the production needs of large-scale converters, and affect repeated use, so as to achieve the effect of convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

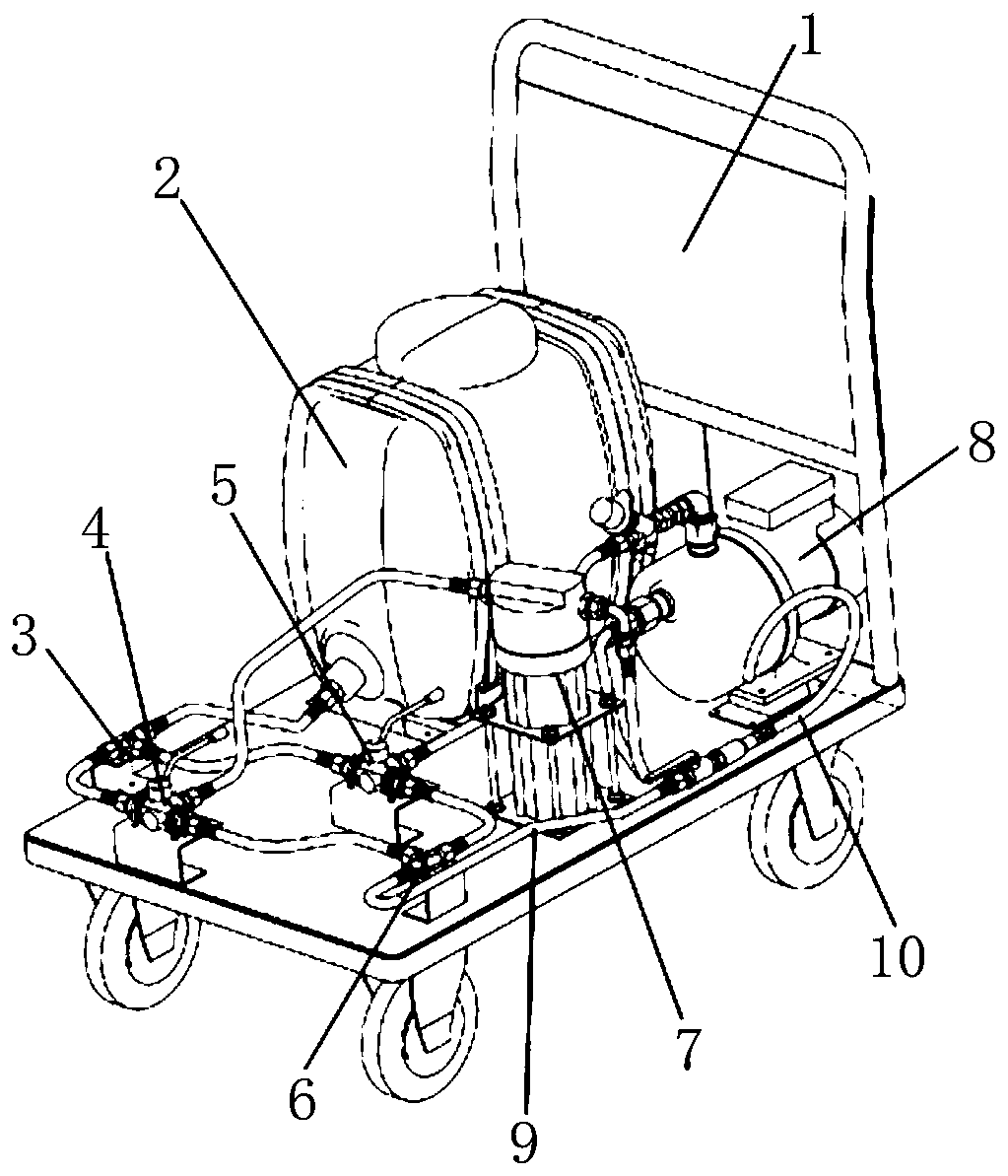

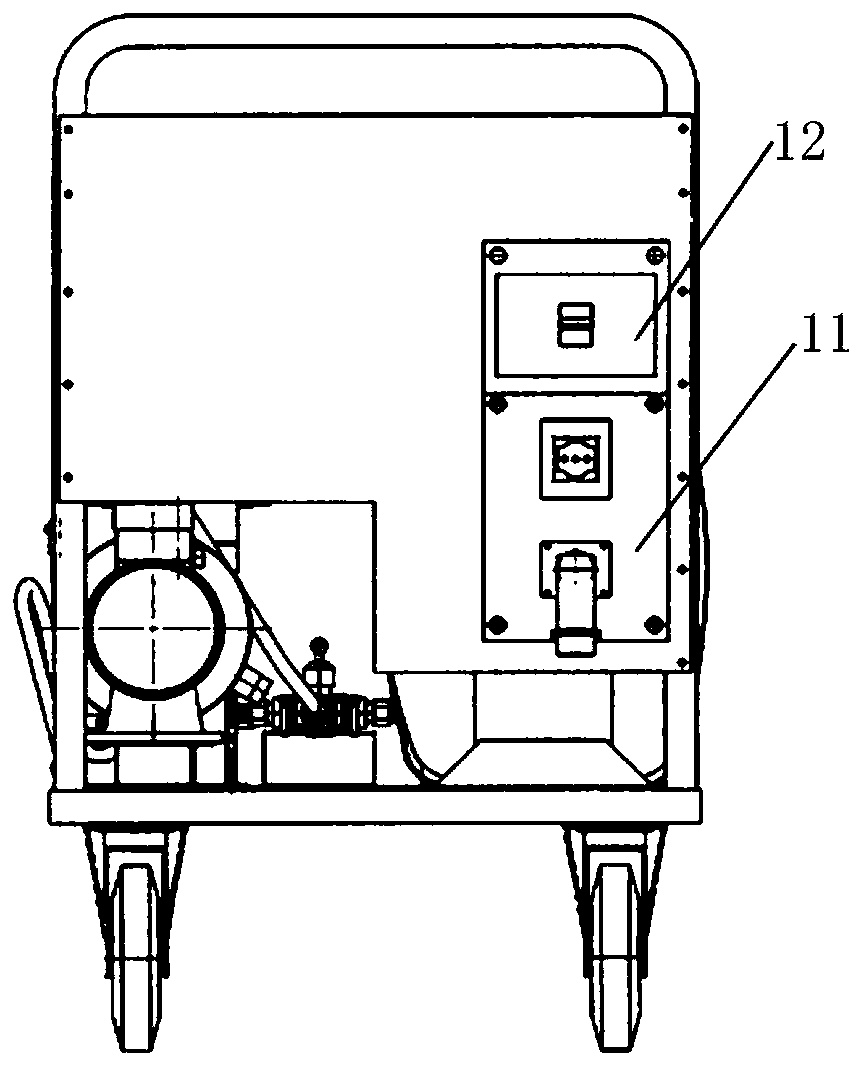

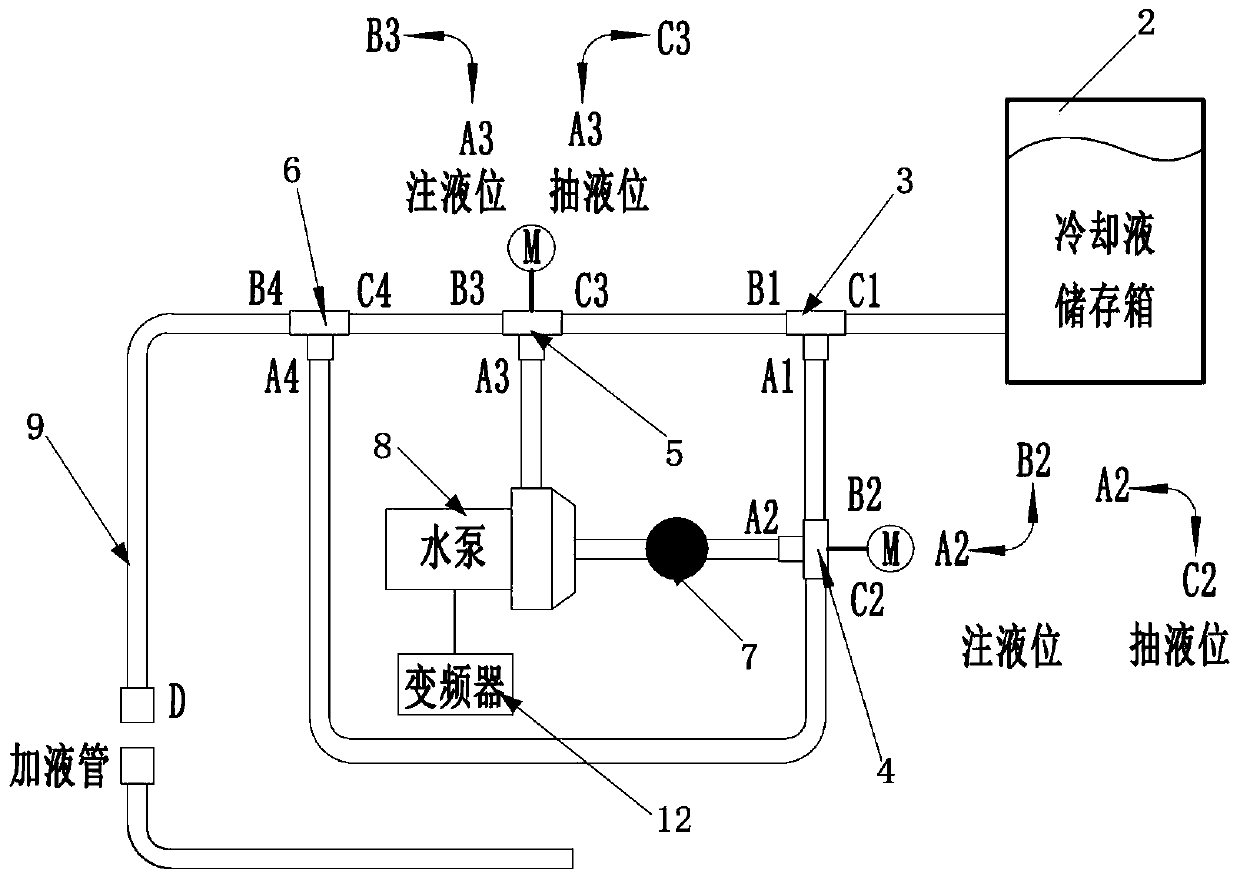

[0027] First, see Figure 1-3 As shown, the present invention provides a novel water-cooling system pumping and injecting integrated device, including a mobile device 1 and a cooling liquid storage tank 2 distributed on the mobile device 1, a control box 11, a three-phase frequency conversion water pump 8, and a frequency converter 12 , filter 7, two tee joints and two reversing valves,

[0028] The frequency converter 12 is connected with the three-phase frequency conversion water pump 8, and is used to control the power supply and speed control of the three-phase frequency conversion water pump 8; the control box 11 is used to control the flow direction of the frequency converter 12 and two reversing valves; the filter 7 is installed in the three-phase The water inlet of the variable frequency water pump 8 is used to filter impurities in the cooling liquid and clean the cooling liquid. One end of the filter 7 is connected to the A2 end of the first reversing valve 4 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com