Efficient and convenient fish killing machine

A convenient and efficient technology, applied in fish processing, fish cleaning/descaling, slaughtering, etc., can solve problems such as low production efficiency, achieve the effect of increasing fish killing rate and improving the ability to collect solid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

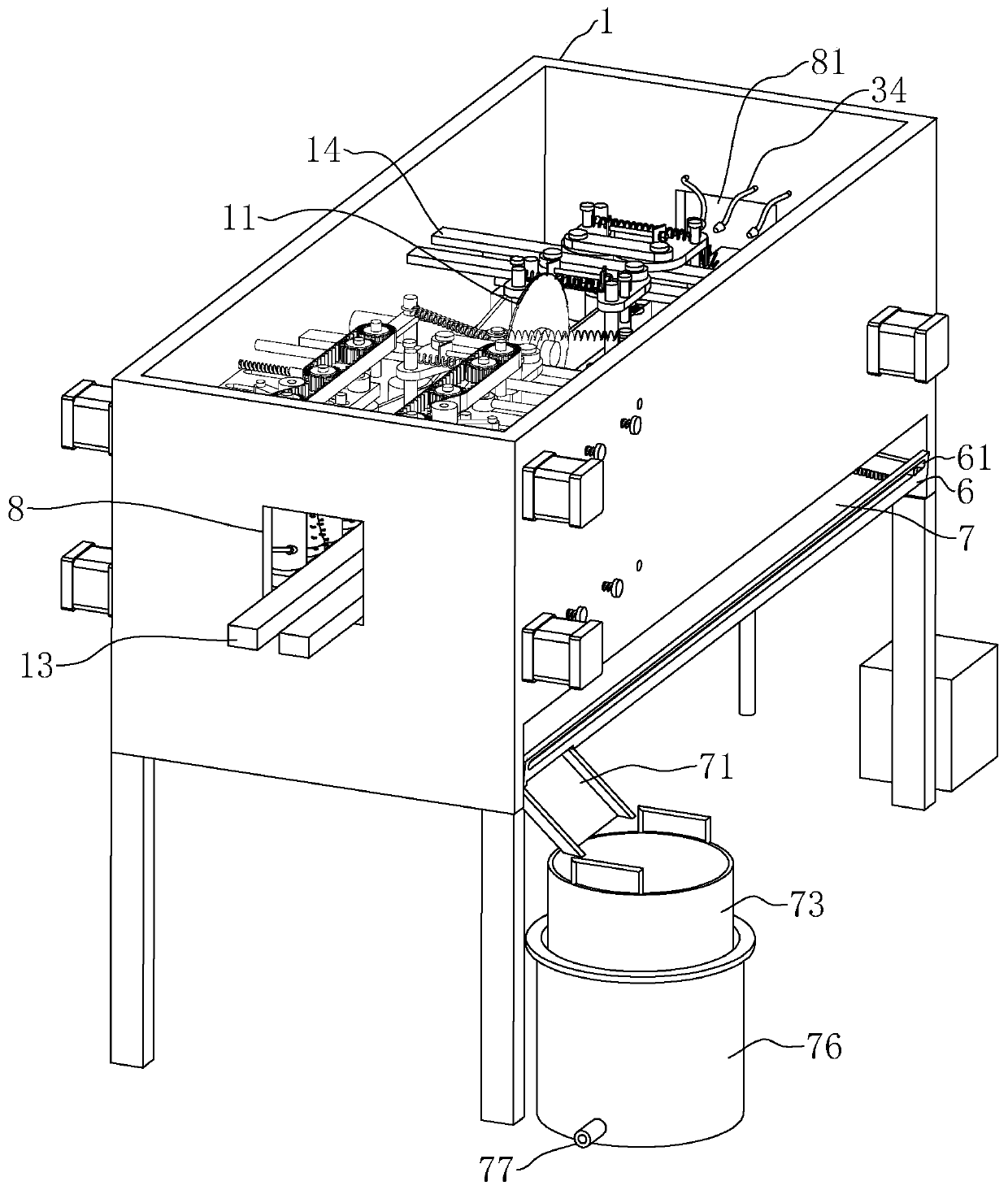

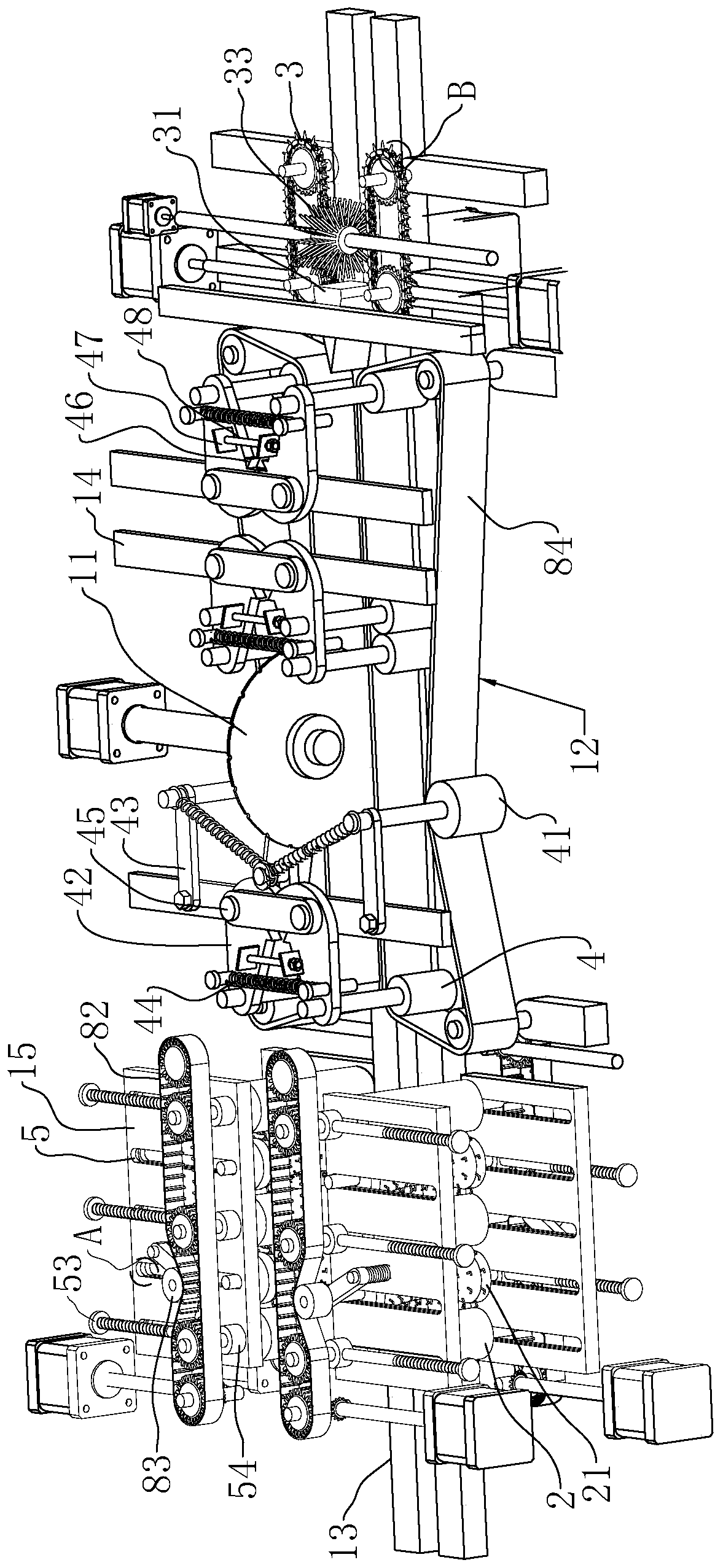

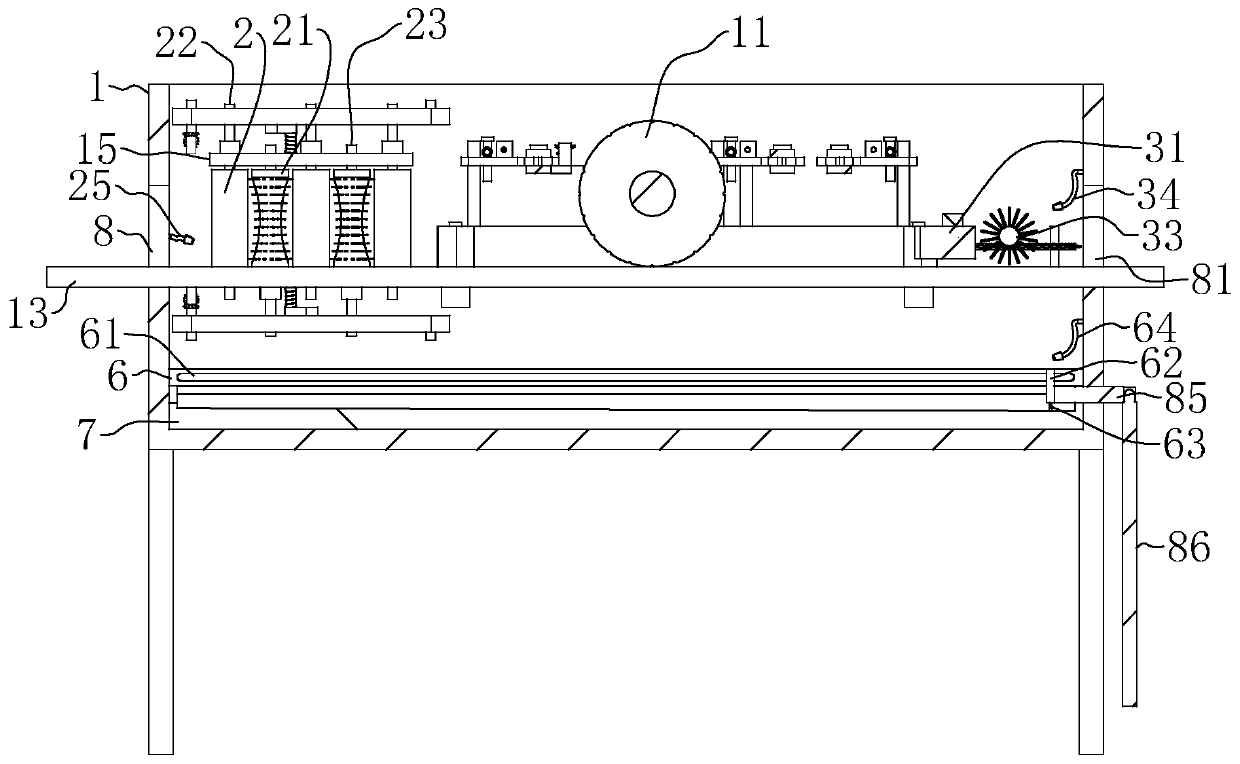

[0040] refer to figure 1 and figure 2 , is an efficient and convenient fish killing machine disclosed in this embodiment, comprising a fish killing frame 1, conveyor belts 12 arranged on opposite sides of the fish killing frame 1 for transporting fish, rotatingly arranged on the conveyor belt Fish-killing round knife 11 on 12 tops.

[0041] The fish-killing frame 1 is a rectangular frame, and two opposite sides on it are respectively provided with an interconnected feed port 8 and a discharge port 81, and the conveyor belt 12 is arranged between the feed port 8 and the discharge port 81. On the opposite sides of the connection line, and between the two conveyor belts 12 in the fish killing frame 1, a support bracket 13 for supporting fish is provided. In this embodiment, the support bracket 13 is connected by bolts It is fixed on the fish-killing frame 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com