Paint brush with detachable hairbrush head

A detachable paint brush technology, applied in the field of paint brushes, can solve the problems of high cost, waste of raw material usage, etc., and achieve the effect of facilitating recycling, improving usage, and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

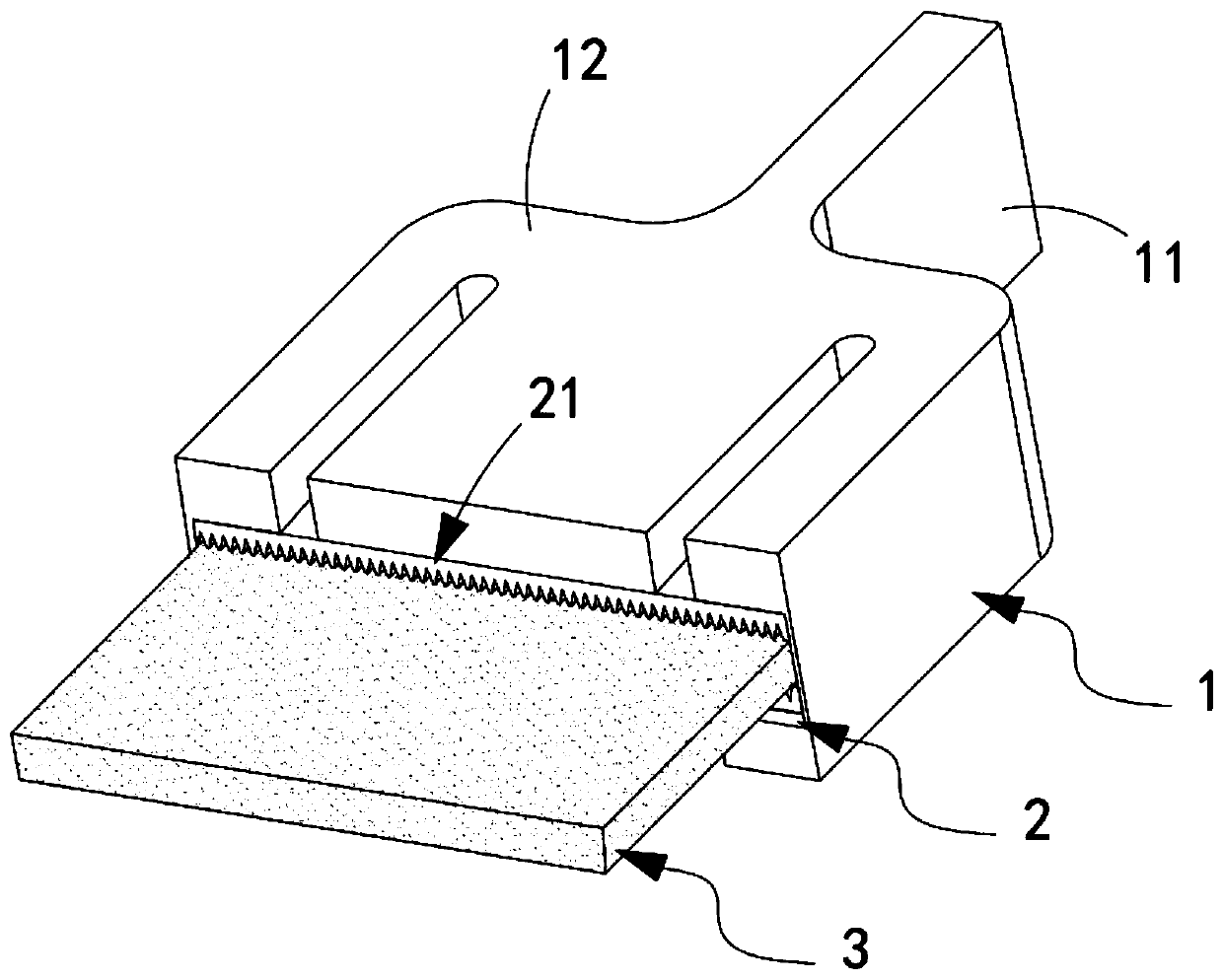

[0055] Such as figure 1 , Figure 4 and Figure 5 As shown, a paint brush with a detachable brush head, comprising:

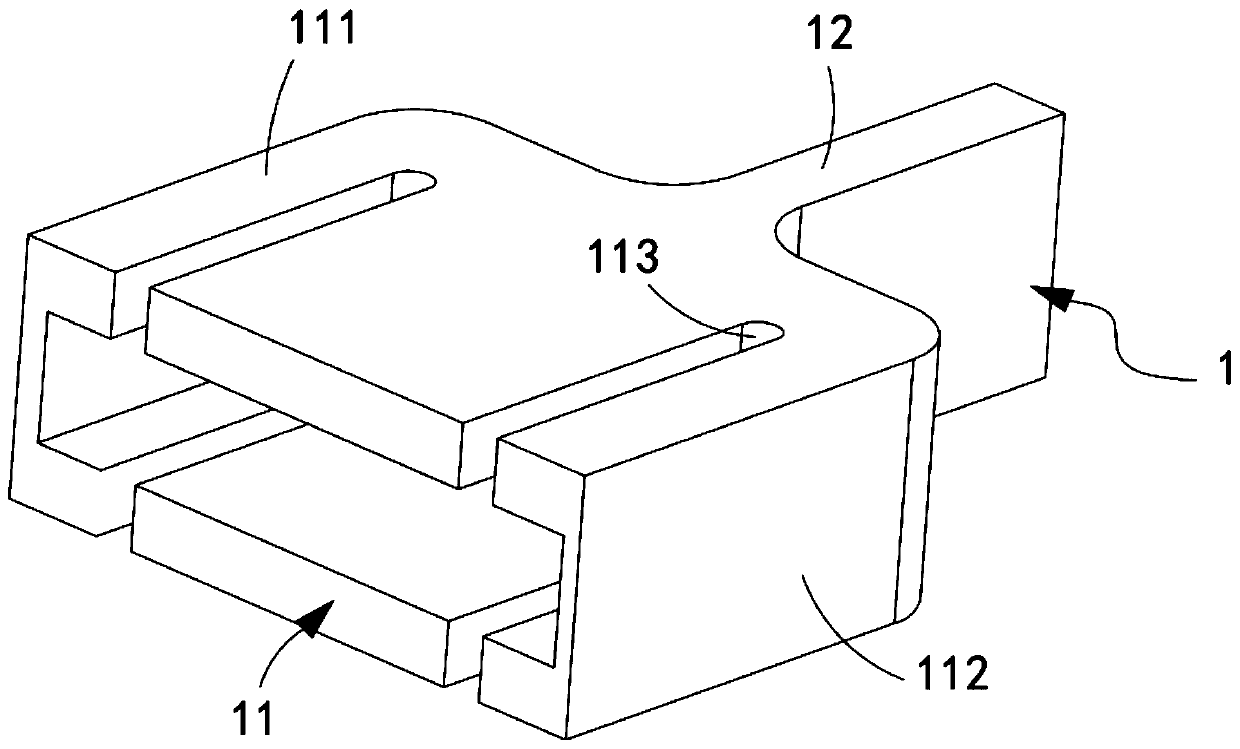

[0056] A handle part 1, the handle part 1 is composed of a mounting part 11 and a grip part 12 from front to back;

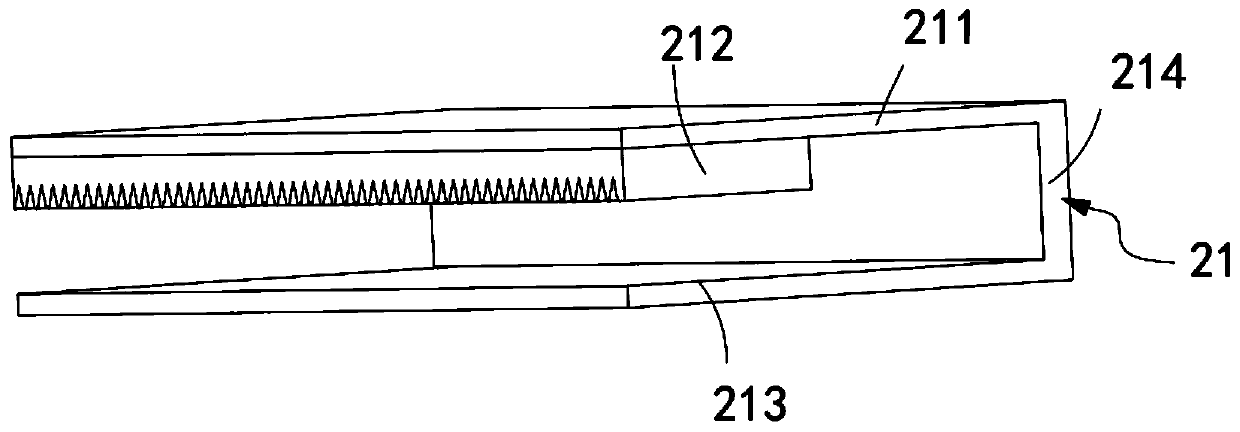

[0057] Clamping part 2, the clamping part 2 is detachably connected with the handle part 1, which includes a support assembly 21 matched with the handle part 1, arranged in the support assembly 21 and along the support assembly 21 A lift assembly 22 that slides vertically in the thickness direction and a snap-fit assembly 23 that is connected to the lift assembly 22 and configured to be connected to the handle part 1; and

[0058] A bristle component 3, the bristle component 3 is clamped in the clamping component 2;

[0059] When the bristle part 3 is replaced, an external force acts on the lifting assembly 22, the clamping part 2 is opened, and the bristle part 3 is automatically taken out for replacement.

[0060] In this embodiment, by in...

Embodiment 2

[0093] Such as Figure 6 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0094] further, such as Figure 5 , Figure 6 As shown, the telescopic unit 224 includes:

[0095] pipe sleeve a2241, the pipe sleeve a2241 is vertically arranged and one end is fixedly connected to the upper bottom plate 211;

[0096] A pipe sleeve b2242, one end of the pipe sleeve b2242 is sleeved outside the pipe sleeve a2241 and is slidably arranged with the pipe sleeve a2241, and the other end of the pipe sleeve b2242 is fixedly connected with the lower clamping plate 221; and

[0097] A spring 2243 , the spring 2243 is arranged in the sleeve a2241 and the sleeve b2242 , and one end of the spring 2243 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com