PVC pipe fitting full-automatic weighing and mixing and powder conveying and supplying system

A technology of PVC pipe material and feeding system, which is applied in the field of automatic weighing and mixing of PVC pipe material and powder conveying and feeding system, can solve the problems of waste in the discharging and feeding process, large dust in the working environment, incorrect weight, etc. Achieve the effect of avoiding weight error, improving working environment and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

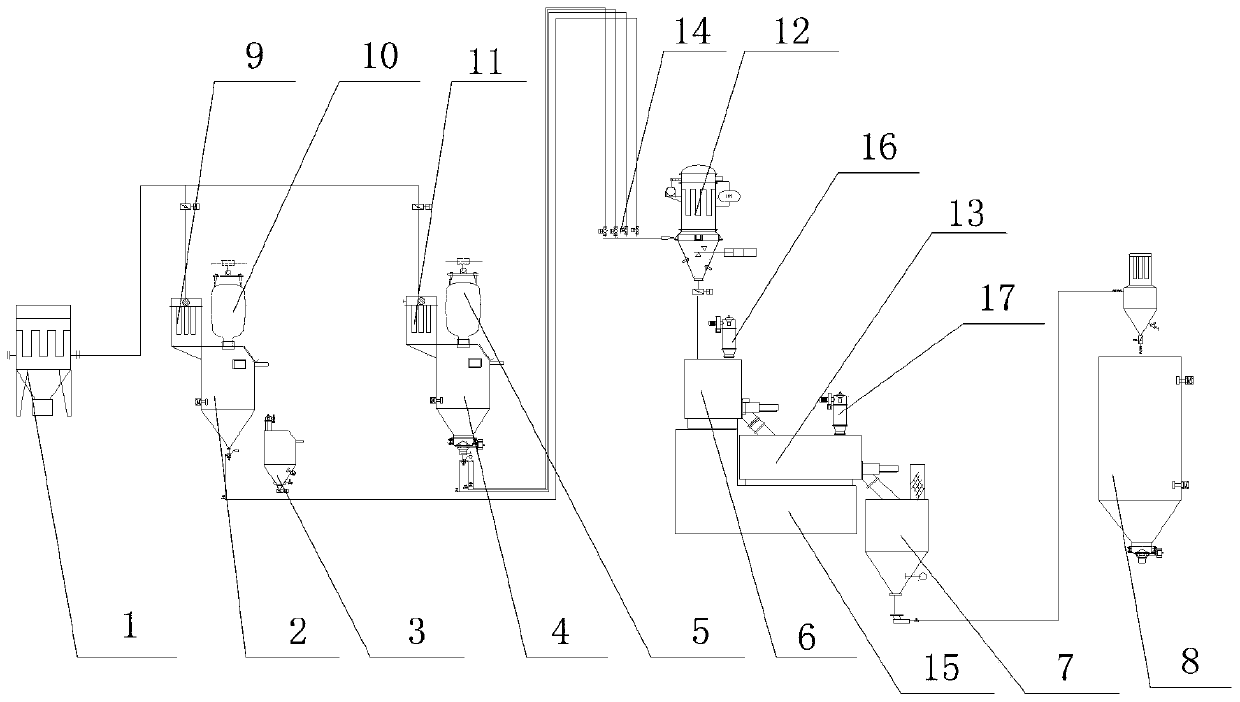

[0025] Such as figure 1As shown, a PVC pipe automatic weighing and mixing and powder conveying and feeding system includes a main dust collector 1, a PVC raw material warehouse 2, and a CaCo3 raw material warehouse 4. The upper part of the PVC raw material warehouse 2 is provided with a PVC raw material warehouse roof Dust collector 9, the top of the CaCo3 raw material warehouse 4 is provided with a CaCo3 raw material warehouse roof dust collector 11, the PVC raw material warehouse roof dust collector 9, the CaCo3 raw material warehouse roof dust collector 11 are connected together with the main dust collector 1, and the PVC raw material warehouse roof dust collector 11 is connected together. The top of the raw material bin 2 is provided with a PVC raw material bin top ton bag 10, the top of the CaCo3 raw material bin 4 is provided with a CaCo3 raw material bin top ton bag 5, and the bottom of the PVC raw material bin 2 is provided with a weighing hopper 12 Connected by a pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com