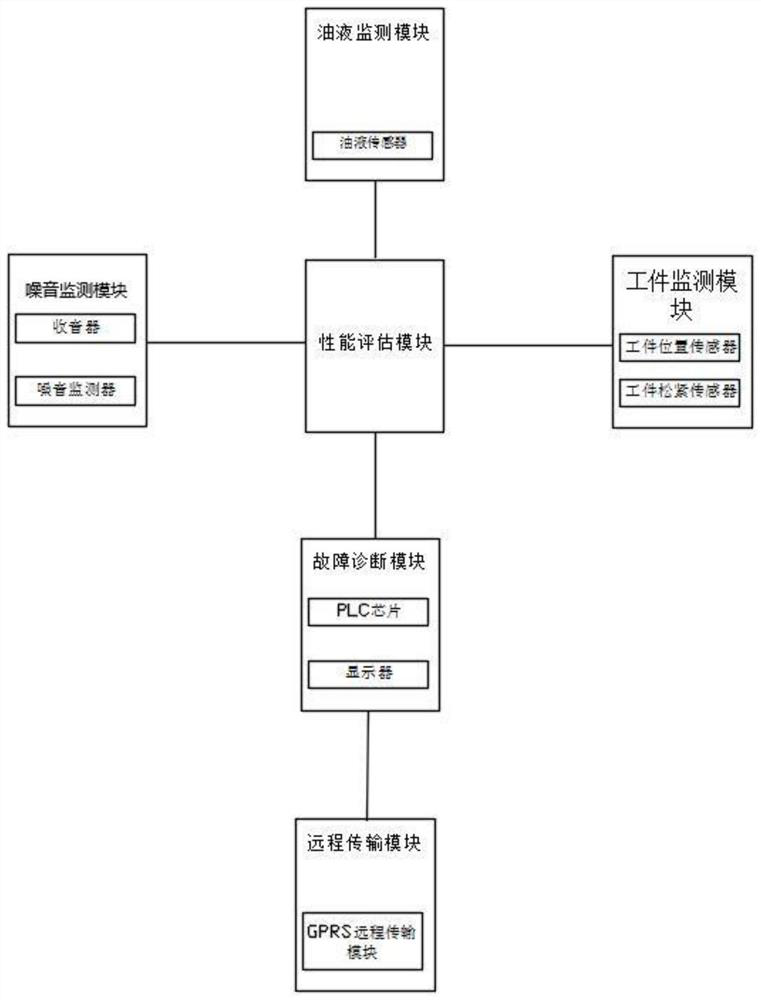

A remote fault diagnosis system and method for a loader

A fault diagnosis system and fault diagnosis technology, applied to earth movers/excavators, construction, etc., can solve problems such as inability to diagnose loader faults, deterioration of system functions, and inability to judge fault points for maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

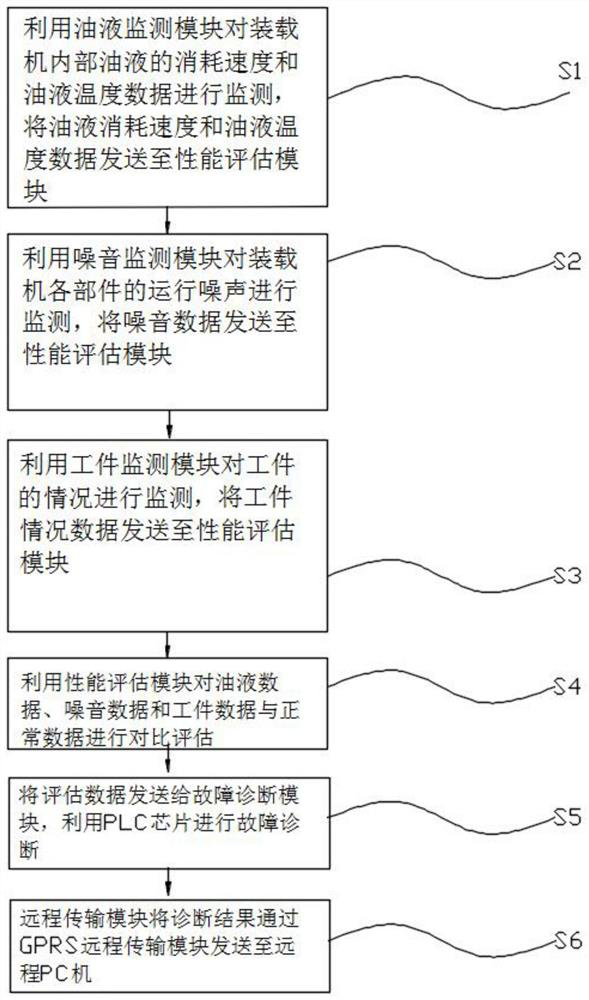

Method used

Image

Examples

Embodiment 1

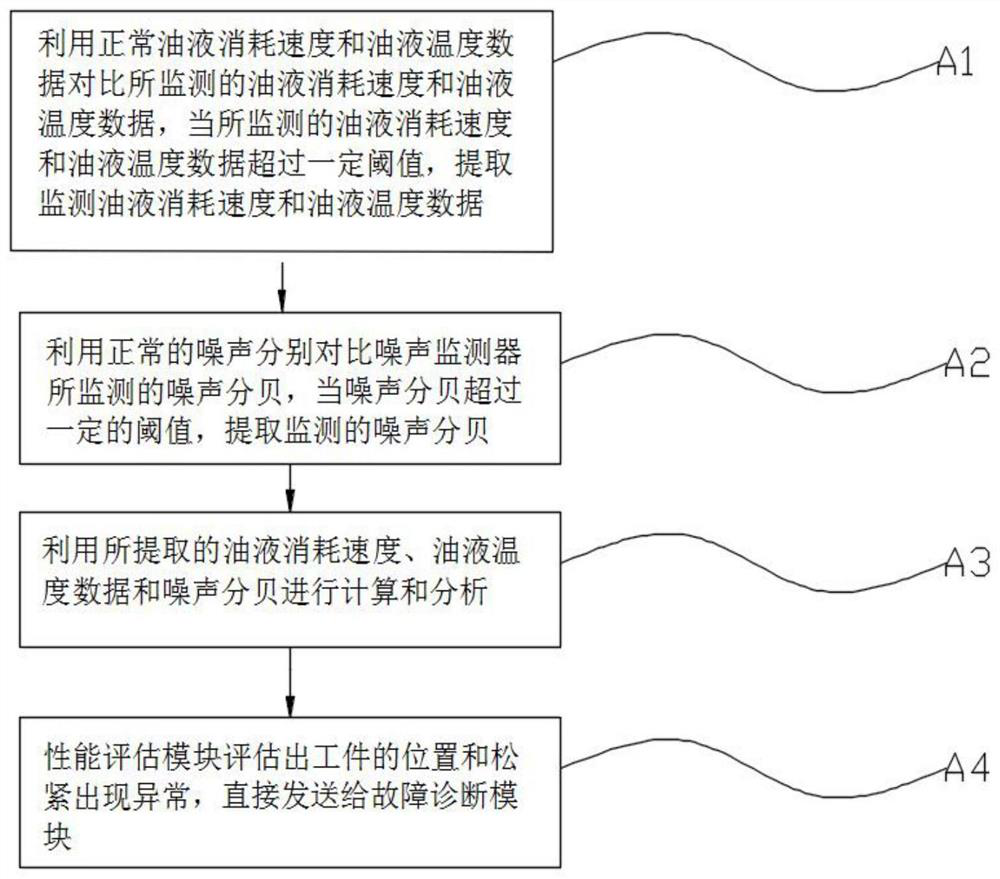

[0080] Example 1: Restricted conditions: when the collected time data is set to 9:00, 9:15, 9:30, 9:45, 10:00, 10:15, when the time is 9:00, 9:15, At 9:30, 9:45, 10:00, and 10:15, the oil sensor monitors the oil consumption rate of the loaded oil at the above times. The values are 13L / h, 13.5L / h, 14.5L / h, 14L / h h, 16L / h, the value of the oil sensor monitoring the temperature data of the loaded oil at the above time is 70 degrees, 71.5 degrees, 72 degrees, 76 degrees, 81 degrees, 83.5 degrees, and the noise monitor is at the above time. The internal noise decibels are monitored at 85dB, 87dB, 91dB, 95dB, 89dB. The oil consumption rate, oil temperature data and noise decibel monitored by the oil sensor and noise monitor are within the normal thresholds. The oil sensor And the noise monitor does not send data to the performance evaluation module.

Embodiment 2

[0081] Example 2: Restricted conditions: when the collected time data is set to 8:00, 8:05, 8:10, 8:15, 8:20, 8:25, when the time is 8:00, 8:05, At 8:10, 8:15, 8:20, and 8:25, the oil sensor monitors the oil consumption rate of the loaded oil at the above times. The values are 13L / h, 14.5L / h, 16L / h, 17.5L / h h, 18.9L / h, the value of the oil sensor monitoring the temperature data of the loaded oil at the above time is 75.5 degrees, 81 degrees, 86 degrees, 95.5 degrees, 97 degrees, the noise monitor at the above time. The values of noise decibels monitored are 85dB, 87dB, 95dB, 103dB, and 101dB. The oil consumption speed, oil temperature data and noise decibel monitored by the oil sensor and noise monitor exceed the normal threshold. The oil temperature data and noise decibel data are sent to the performance evaluation module, and the different thresholds of the collected oil consumption speed, oil temperature data and noise decibel are set to L1, L2, and L3, where L1=19L / h, ...

Embodiment 3

[0087]Example 3: Restricted conditions: when the collected time data is set to 10:00, 10:10, 10:20, 10:30, 10:40, 10:50, when the time is 10:00, 10:10, At 10:20, 10:30, 10:40, and 10:50, the oil sensor monitors the oil consumption rate of the loaded oil at the above times. The values are 17L / h, 18.5L / h, 19.8L / h, 21L / h h, 22.3L / h, the value of the oil sensor monitoring the temperature data of the loaded oil at the above time is 86 degrees, 93 degrees, 97 degrees, 102 degrees, 99 degrees, the noise monitor at the above time The noise decibel values monitored are 95dB, 103dB, 121dB, 119dB, and 125dB. The oil consumption speed, oil temperature data and noise decibel monitored by the oil sensor and noise monitor exceed the normal thresholds. The oil temperature data and noise decibel data are sent to the performance evaluation module, and the different thresholds of the collected oil consumption speed, oil temperature data and noise decibel are set to L1, L2, and L3, where L1=1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com