A multifunctional gas sensor calibration container

A gas sensor and calibration container technology, which is applied to standard gas analyzers, the structural details of gas analyzers, and the analysis of gas mixtures, etc. and other problems to achieve the effect of ensuring the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below with reference to the accompanying drawings and specific preferred embodiments.

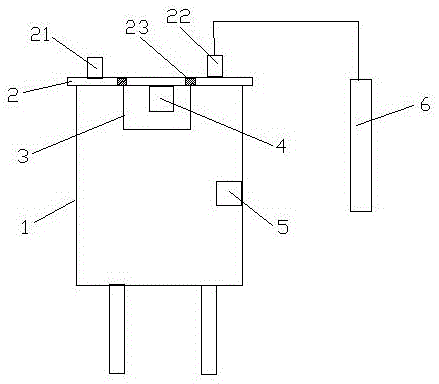

[0035] like figure 1 As shown, a multifunctional gas sensor calibration container includes a main cavity 1 with a top opening and a cover plate 2, and the cover plate 2 is sealed with the top opening of the main cavity 1 through bolts and sealing rings.

[0036] A ring-shaped electromagnet is nested in the center of the upper surface of the cover plate.

[0037] The cover plates located on both sides of the annular electromagnet are respectively provided with a gas inlet pipeline and a gas outlet pipeline.

[0038] Further, the tail end of the gas outlet pipeline is preferably connected to the recovery bottle through a gas check valve.

[0039] A gas sensor connected to the computer is fixedly arranged on the lower surface of the cover plate located in the annular cavity area of the annular electromagnet.

[0040] The mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com