Cutter set for crushing pump

A technology for cutting knives and crushing pumps, applied to pumps, pump components, non-variable pumps, etc., can solve problems such as low cutting efficiency, increased vibration or shaft power, and frequent failures, so as to reduce on-site maintenance costs and improve The effect of using abrasion resistance and reducing the chance of entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

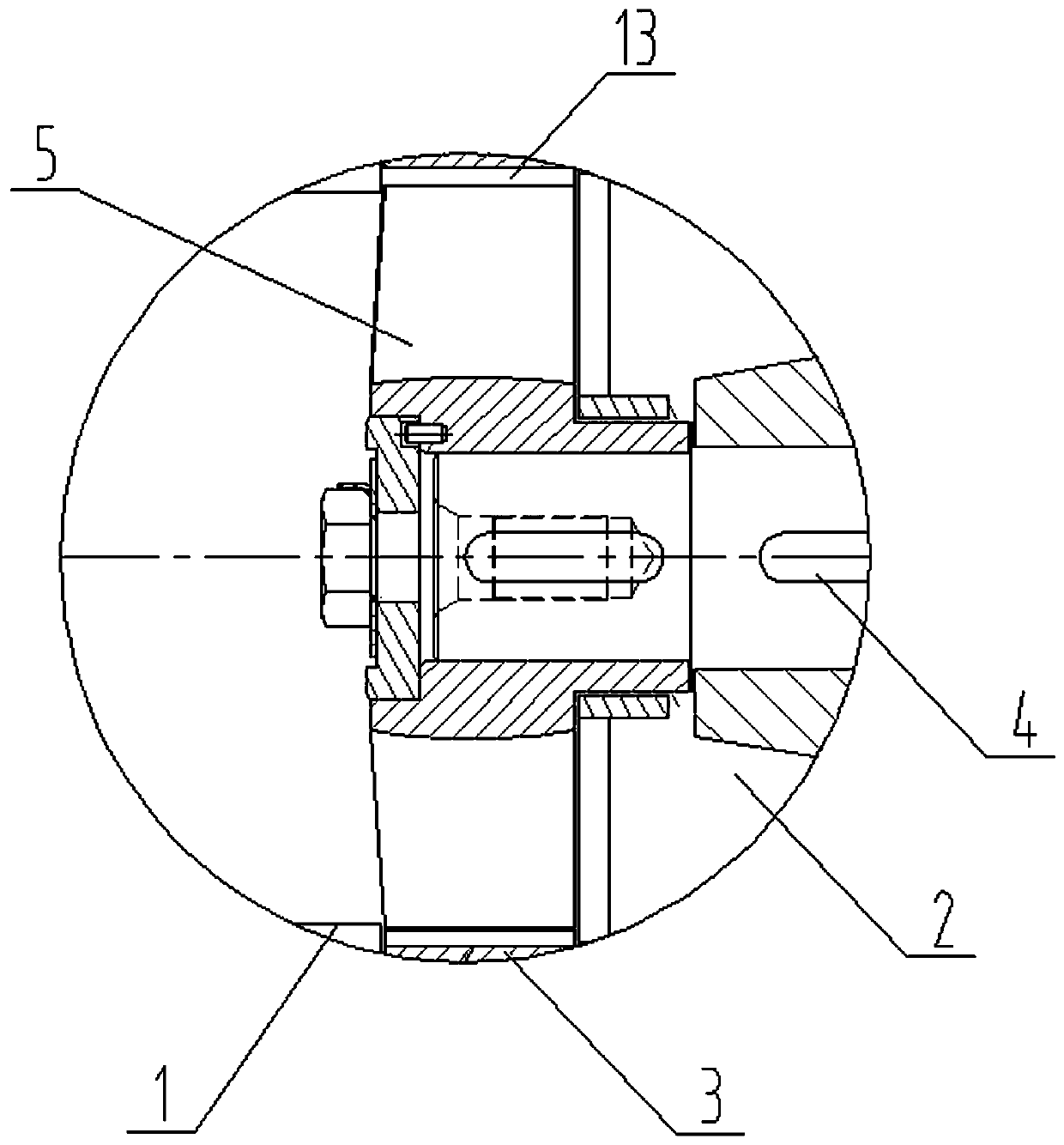

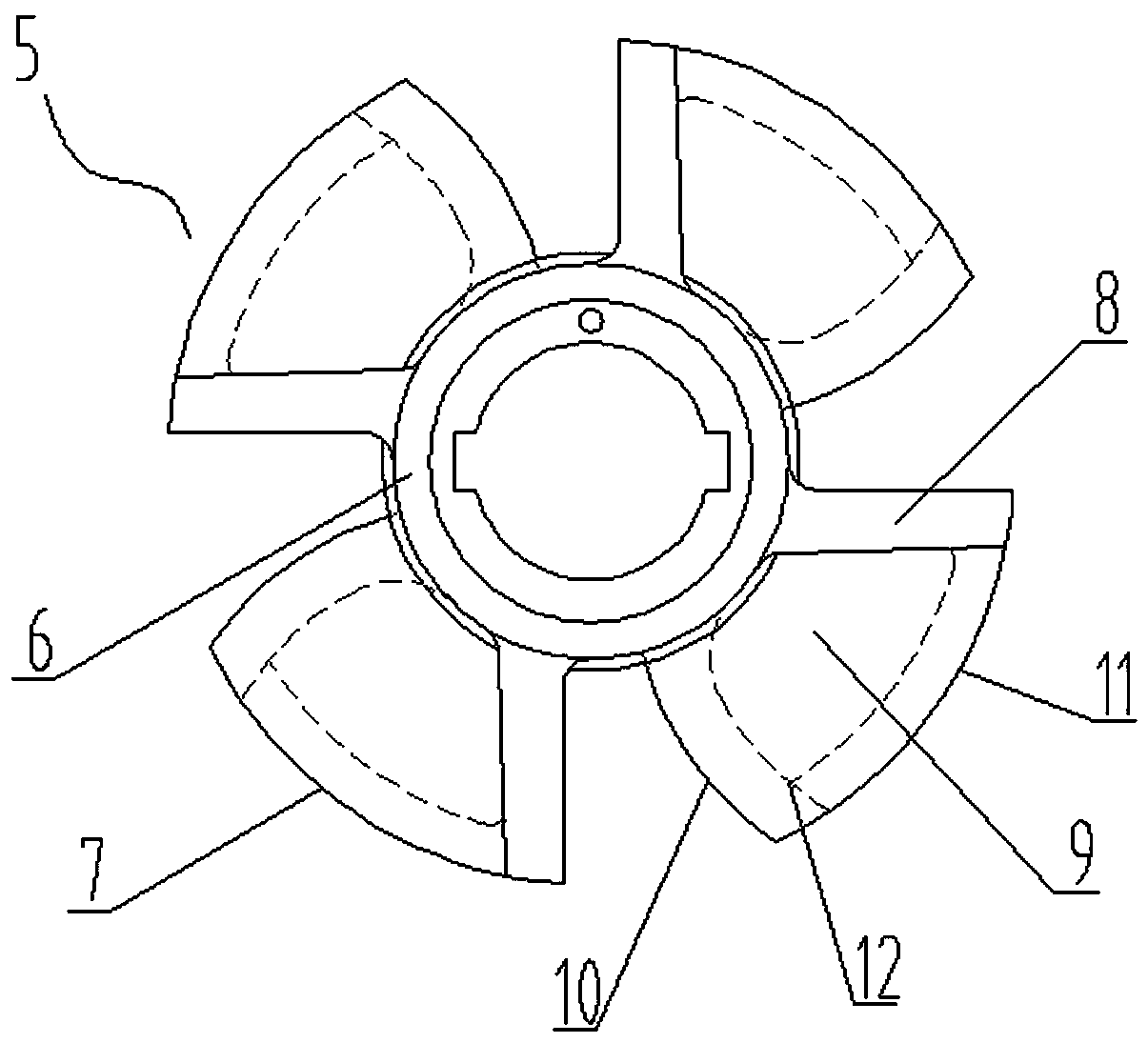

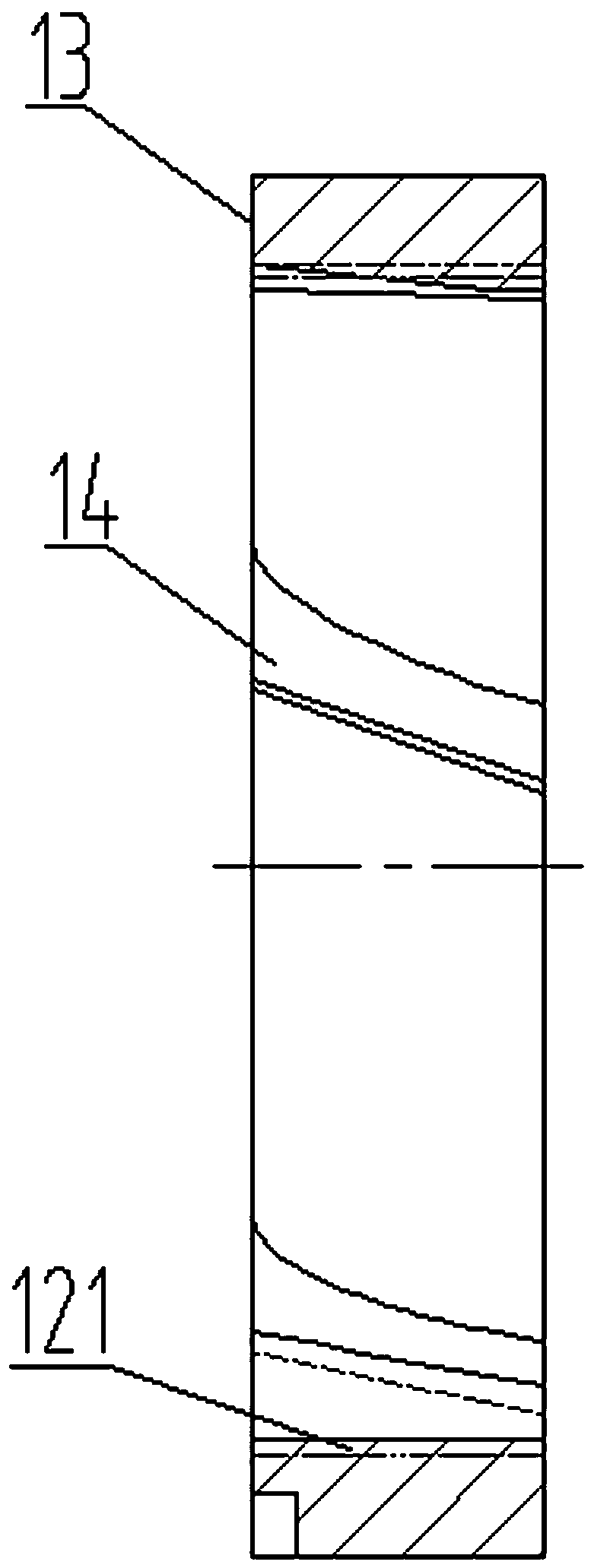

[0017] Figure 1-3 As shown, a cutting knife set for a crushing pump includes a cutting wheel 5 sleeved and fixed on the front end of the impeller 2 on the pump shaft 4, and a cutting sleeve 13 that is sleeved outside the cutting wheel and embedded in the pump body 2 with a clearance fit. The cutting wheel 5 includes a rim 6 and blades 7. The rim 6 is connected to the pump shaft 4 via a key and is fixed and locked. A plurality of blades 7 are uniformly connected to the outer periphery of the rim 6. The blades 7 include ribs 8 and blades. 9. The rib part 8 is a rib structure extending outward in a straight line or arc from the rim, and one side of the leaf part 9 is connected to the upper side of the rib part 8, and the leaf part 9 goes from one side to the other side around the circumferential direction The height of the side plane is reduced and extended (o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com