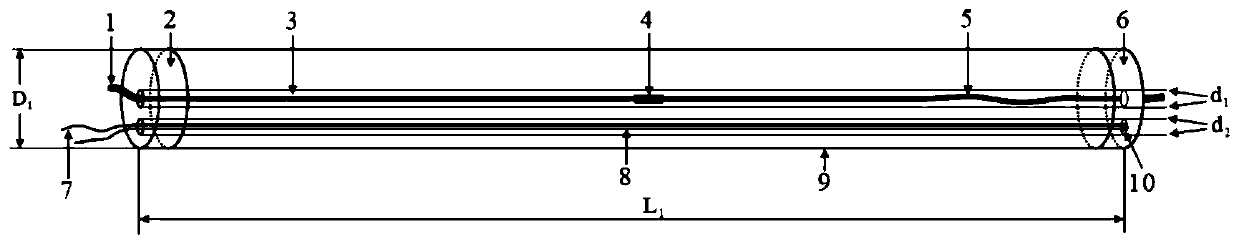

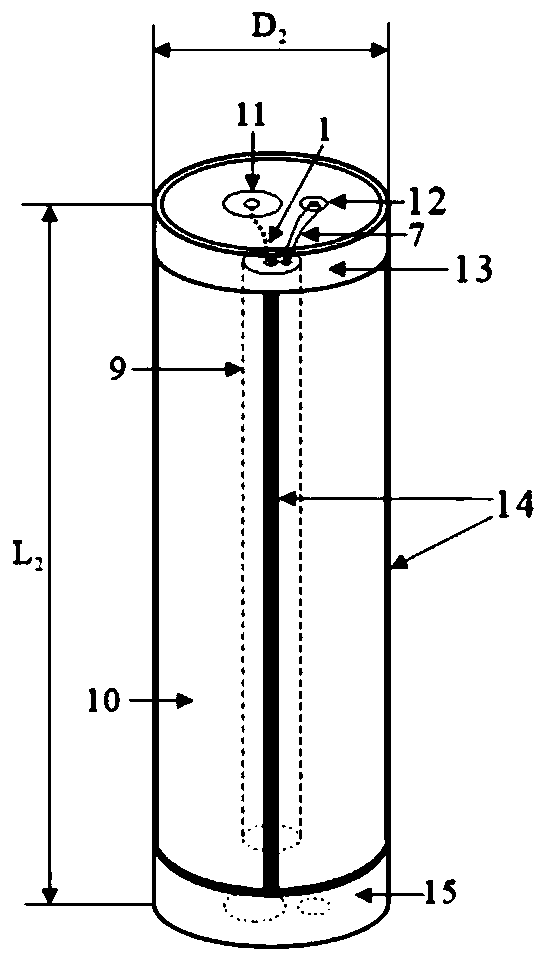

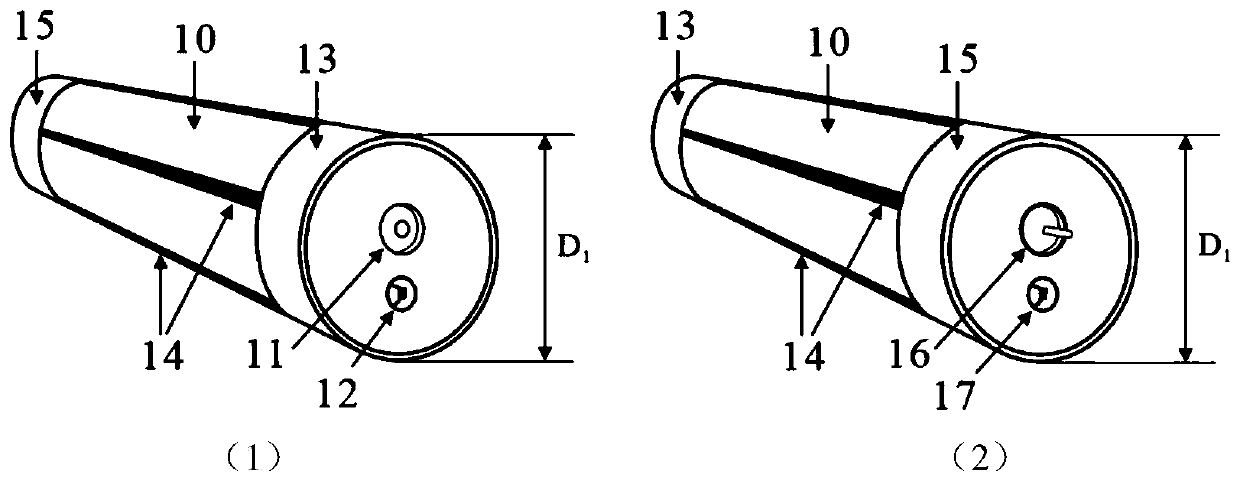

Fiber grating-based soil matric suction quasi-distributed in-situ measurement method and apparatus

A technology of matrix suction and fiber grating, applied in the direction of measuring device, phase influence characteristic measurement, soil material test, etc., to achieve the effect of convenient operation, improved spatial resolution, and small soil disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Indoor calibration experiment using the method and device of the present invention for a matrix suction sensor. Specific steps are as follows:

[0080] Step 1. Weigh the sensor rod to obtain the quality of the clay rod;

[0081] Step 2. For the same clay stick, configure different water states of the clay stick by controlling the water content, and combine the filter paper suction test method to calibrate 16 to 20 groups of matrix suction of the clay stick at different saturations, and fit the matrix suction of the clay stick The relationship with the change of water saturation is the soil-water characteristic curve of the clay stick;

[0082] Step 3. Fully mix and stabilize the manufactured and packaged matrix suction sensor with water. The matrix suction sensor is a matrix suction sensor based on fiber Bragg grating pulse heating, and is composed of a clay rod, an optical fiber, a heating resistance wire, and an optical fiber grating;

[0083] Step 4: During the dry...

Embodiment 2

[0088] The method and device of the invention are used to carry out in-situ tests for distributed measurement of soil matrix suction, and to monitor the soil ice content of different depths of soil. The soil of a clayey soil area in Nanjing was selected as the test site.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com