System and method for judging motor assembly in place based on smart camera

A smart camera and judgment method technology, applied in general control system, control/adjustment system, electrical program control, etc., can solve problems such as difficulty in ensuring accuracy, and achieve the effect of avoiding negligence and improving assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

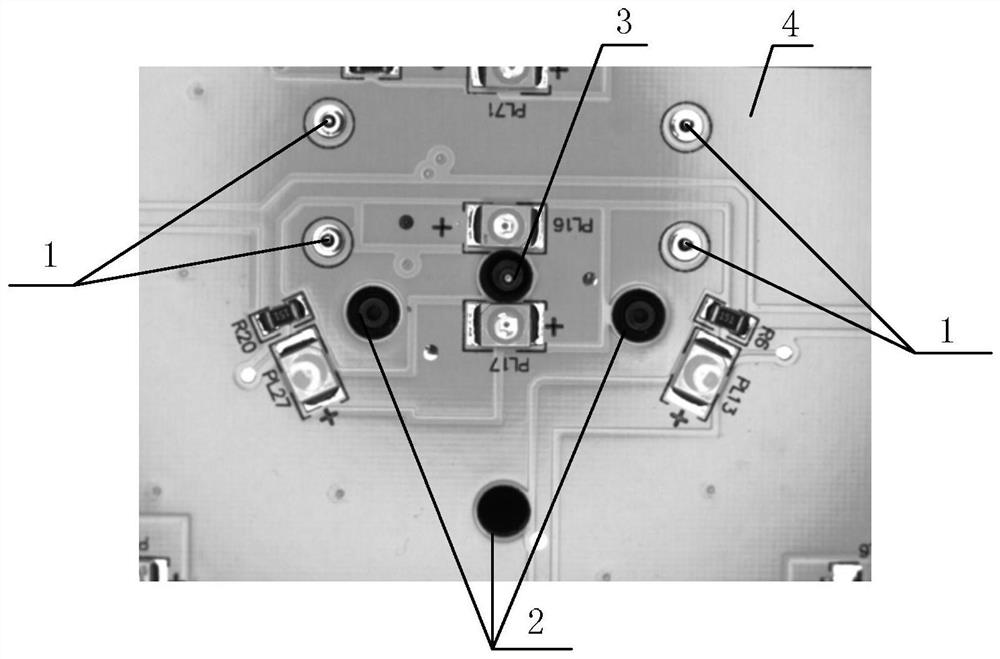

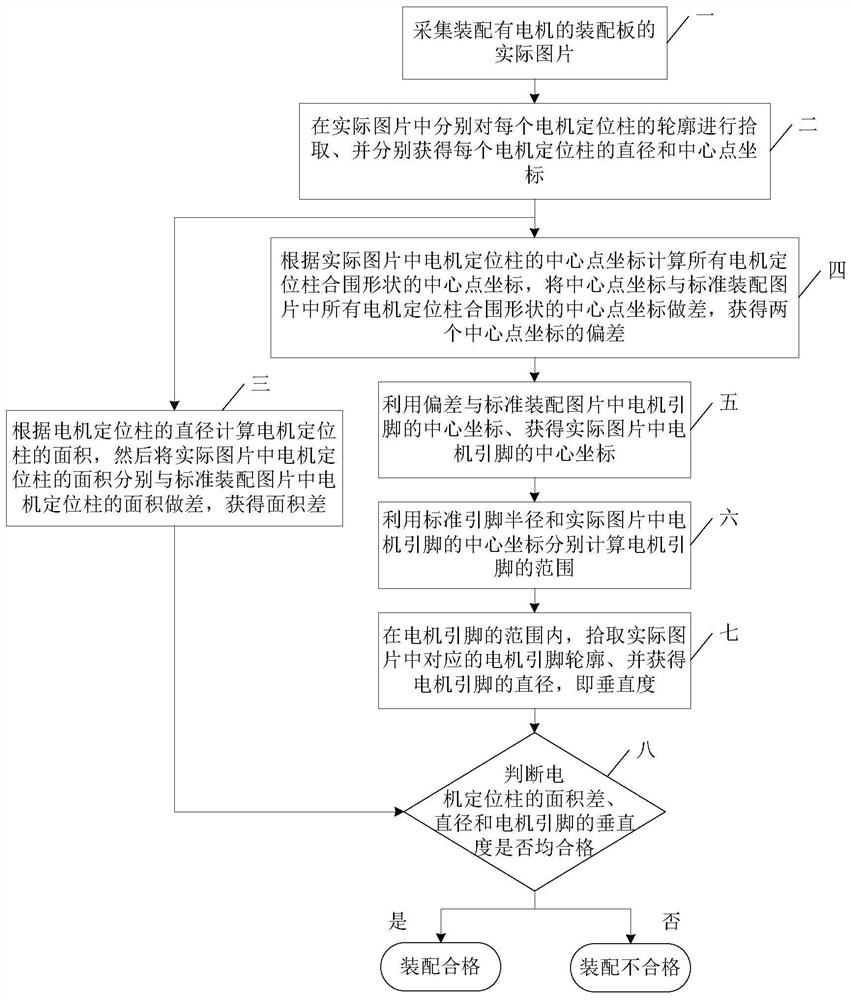

[0048]Specific embodiment one: referencefigure 1 withfigure 2Specifically describing this embodiment, the smart camera-based motor assembly determination method described in this embodiment includes the following steps:

[0049]Step 1: Use a smart camera to collect actual pictures of the assembly board 4 equipped with a motor;

[0050]Step 2: In the actual picture, by picking the color of the motor positioning column 2 to obtain the contours of the three motor positioning columns 2 respectively, the contours are circular, and respectively calculate the diameter and center point coordinates of each motor positioning column 2. Then perform step three and step four simultaneously;

[0051]Step 3: Calculate the area of each motor positioning column 2 according to the diameter of each motor positioning column 2, and then calculate the area of each motor positioning column 2 in the actual picture with the area of the corresponding motor positioning column 2 in the standard assembly picture D...

specific Embodiment approach 2

[0063]Specific embodiment two: referencefigure 1 Specific description of this embodiment, the smart camera-based motor assembly determination system in this embodiment includes the following units:

[0064]Collection unit: collect actual pictures of the assembly board 4 equipped with the motor;

[0065]Motor positioning column parameter acquisition unit: By picking the color of the motor positioning column 2 in the actual picture, the contour of each motor positioning column 2 is obtained. The contour is circular, and the diameter and center point of each motor positioning column 2 are obtained respectively coordinate;

[0066]Motor positioning column area difference acquisition unit: calculate the area of each motor positioning column 2 according to the diameter of each motor positioning column 2, and then compare the area of each motor positioning column 2 in the actual picture with the corresponding motor positioning in the standard assembly picture Make the difference in the area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com