Infrared image cross grain removing processing method and processing device and storage device

An infrared image, horizontal stripe technology, applied in the field of thermal imaging, can solve the problems of difficult hardware implementation, inconsistent output circuit bias voltage, large error, etc., to achieve the effect of maintaining clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The solutions of the embodiments of the present application will be described in detail below in conjunction with the accompanying drawings.

[0023] In the following description, for purposes of illustration rather than limitation, specific details, such as specific system architectures, interfaces, and techniques, are set forth in order to provide a thorough understanding of the present application.

[0024] The terms "system" and "network" are often used interchangeably herein. The term "and / or" in this article is just an association relationship describing associated objects, which means that there can be three relationships, for example, A and / or B can mean: A exists alone, A and B exist simultaneously, and there exists alone B these three situations. In addition, the character " / " in this article generally indicates that the contextual objects are an "or" relationship. In addition, "many" herein means two or more than two.

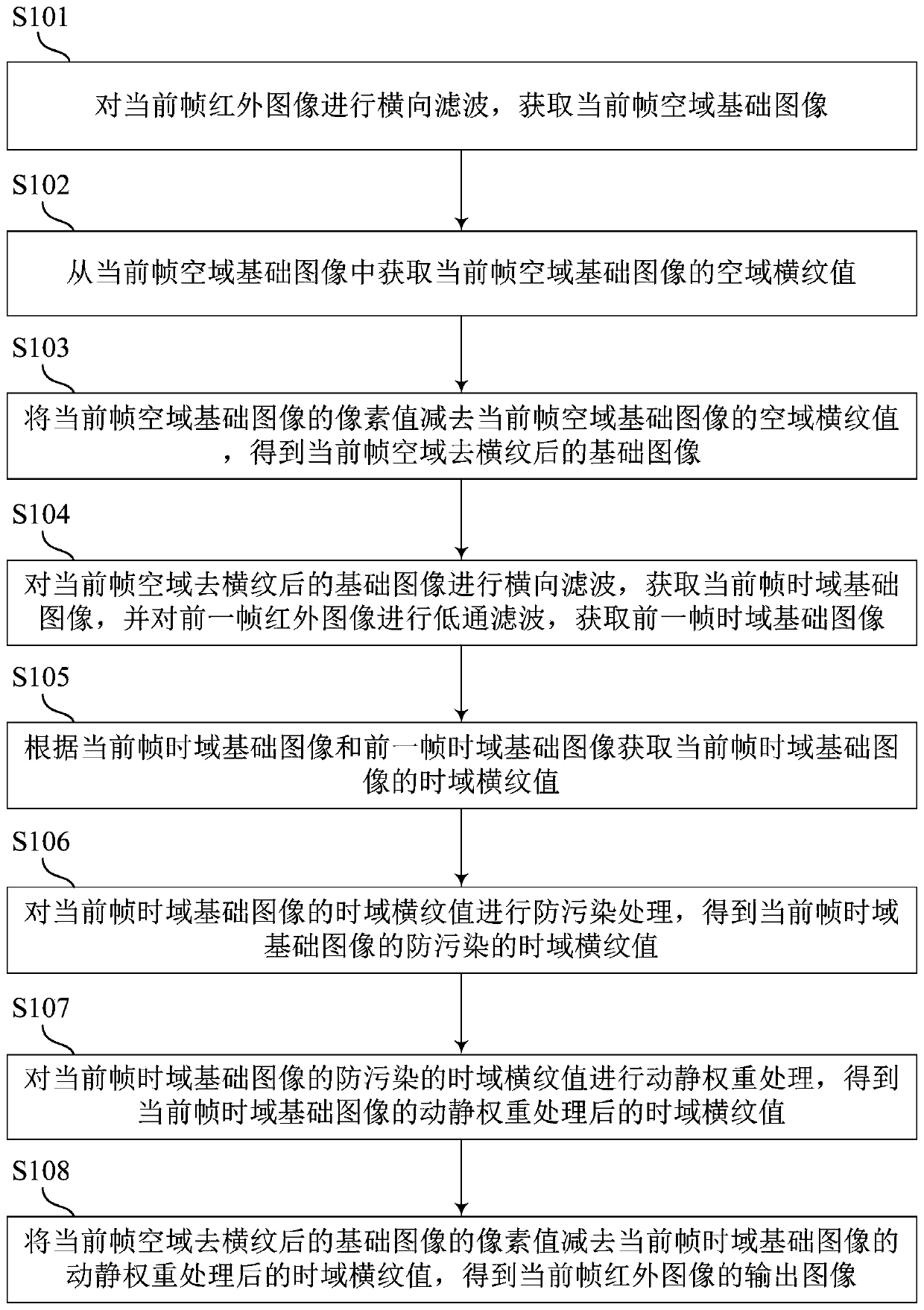

[0025] see figure 1 , figure 1 It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com