Snow removal device for high-altitude power lines

A high-altitude power and power line technology, applied in overhead installation, cable installation, electrical components, etc., can solve the problems of power line safety hazards, grid failures, high design costs and maintenance costs, and achieve low cost, simple structure, and easy promotion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

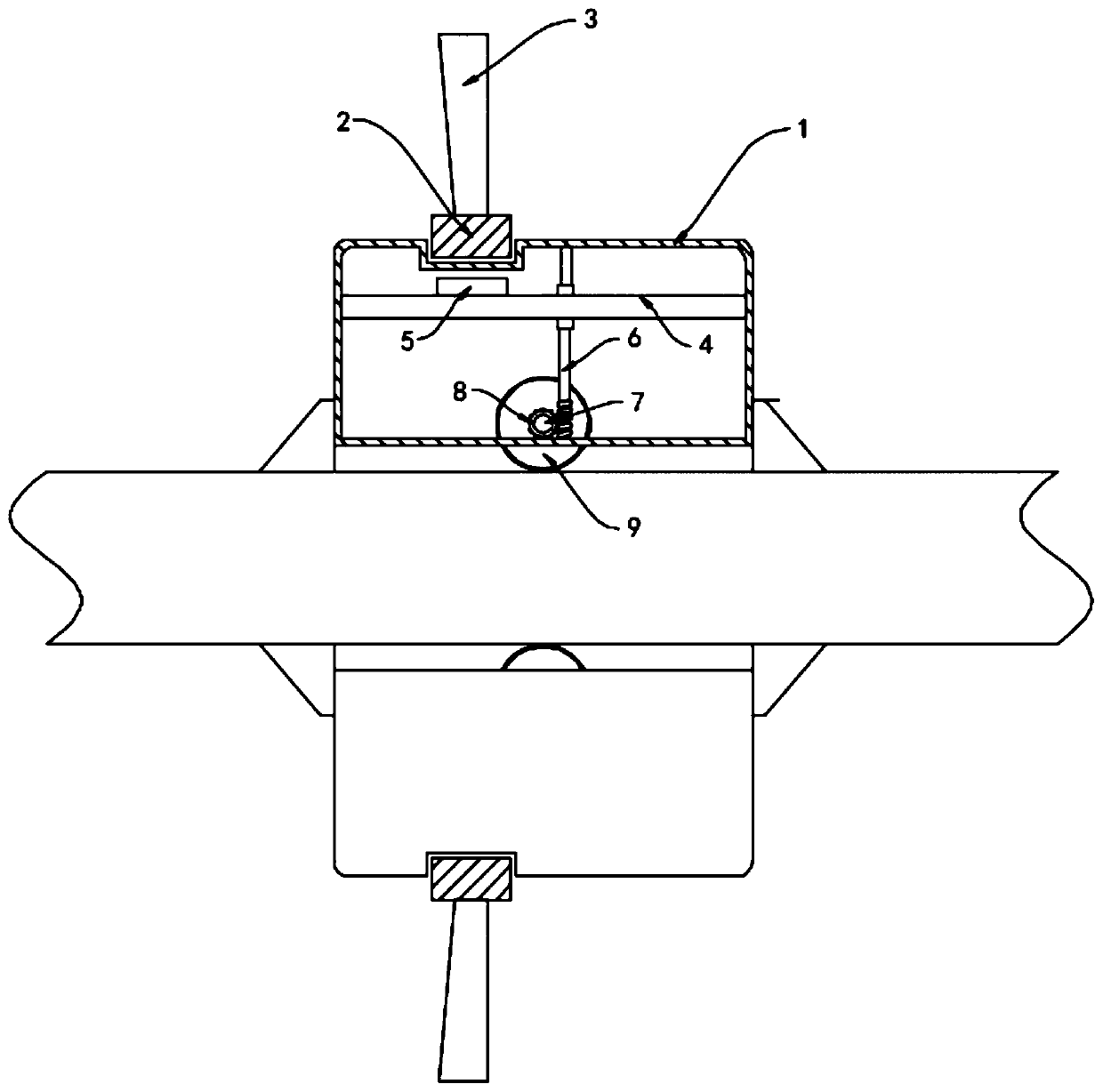

Embodiment 1

[0017] Such as figure 1 As shown, a snow removal device for high-altitude power lines includes an annular casing 1 sleeved outside the power line, and a slip ring 2 is rotatably connected to the outside of the annular casing 1. The slip ring 2 consists of two magnetic halves connected end to end and opposite in magnetic Composed of circular rings, the outer wall of the slip ring 2 is equidistantly arranged with a plurality of fan blades 3 in the circumferential direction, and the inner wall of the annular housing 1 is slidably connected with a horizontally arranged lifting plate 4, and the upper surface of the lifting plate 4 is fixedly connected. Permanent magnet block 5 is arranged.

[0018] In this embodiment, a worm 6 is rotatably connected to the inner side wall of the annular housing 1, and the upper half of the worm 6 is provided with threads, and the upper end of the worm 6 passes through the lifting plate 4 and is threadedly connected with the lifting plate 4. The ann...

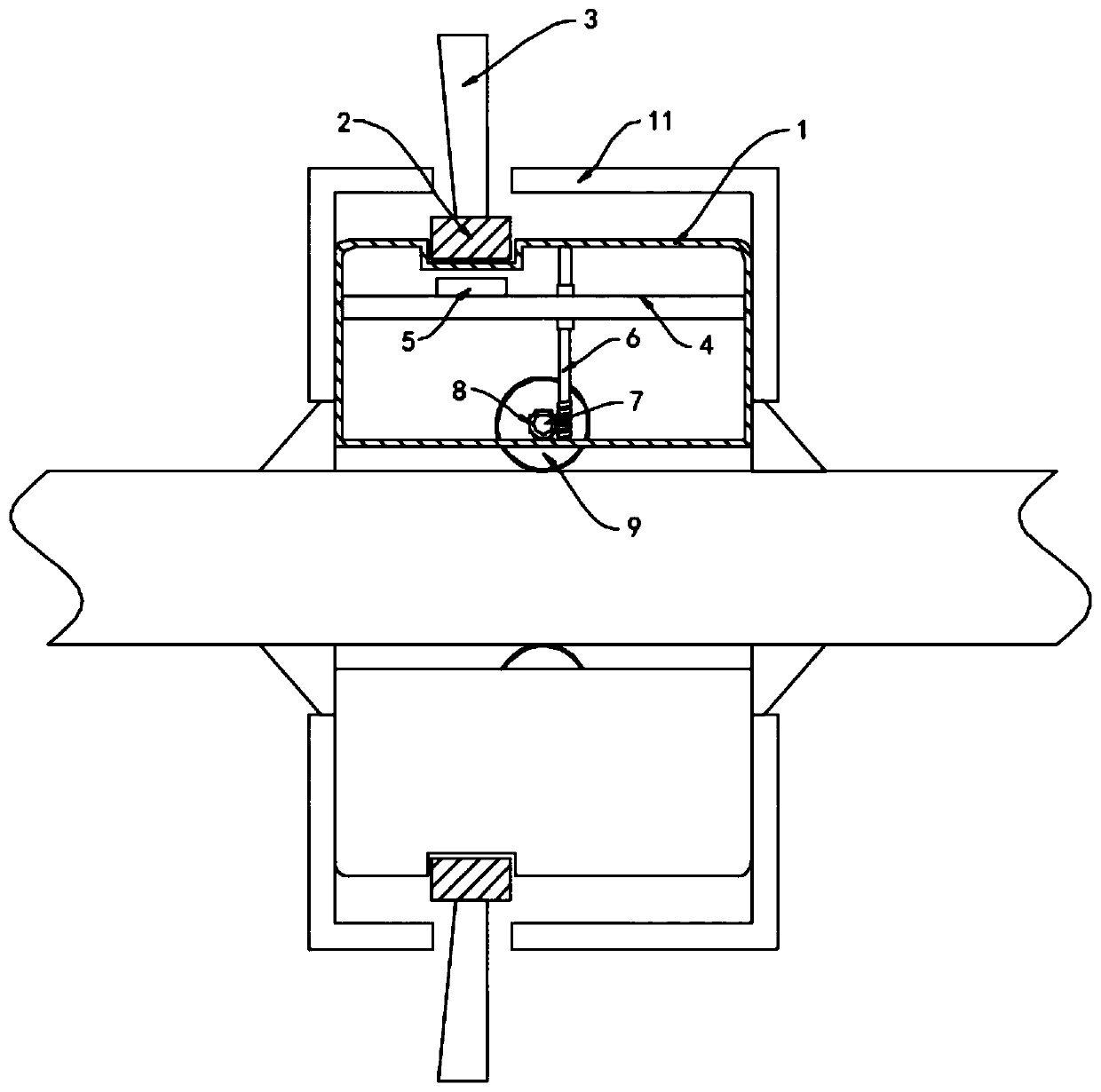

Embodiment 2

[0021] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that a plurality of guide pipes 11 are arranged on the side wall of the annular housing 1, and the lower ends of the guide pipes 11 extend to the top of the snow removal plate 10, and the guide pipes The upper end of the pipe 11 is extended to the fan blade 3 and arranged there.

[0022] In this embodiment, the upper end of the guide tube 11 is extended to the fan blade 3. When the snow removal plate 10 slides on the power line, the snow accumulated on the power line is scraped off to the surface of the snow removal plate 10, and the snow is passed through the flow guide. The pipe 11 is transported to the fan blade 3, and the fan blade 3 rotates, and under the action of centrifugal force, the accumulated snow is thrown around to prevent the accumulated snow from rising and attaching to the power line again, and the snow removal effect is better.

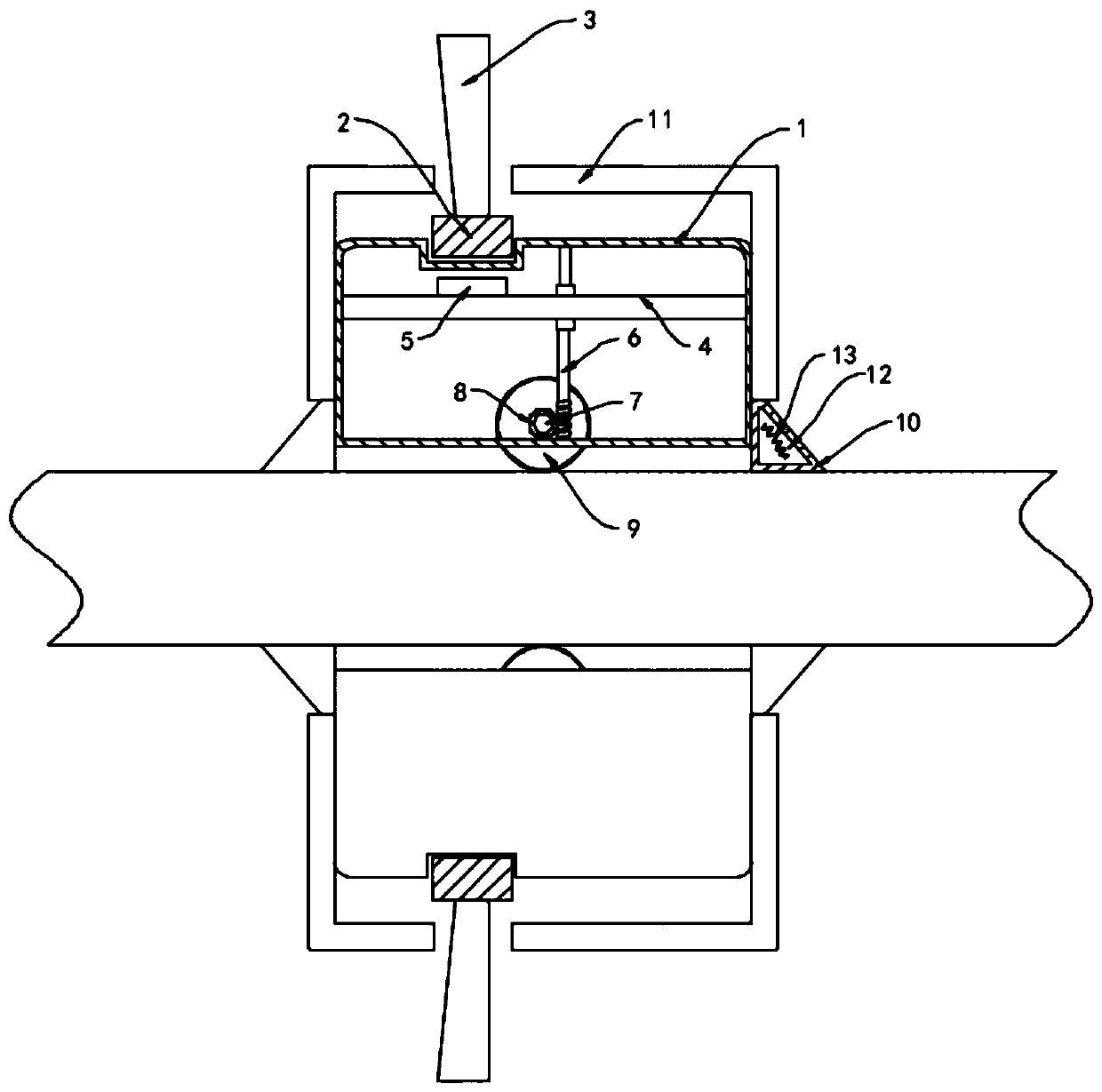

Embodiment 3

[0024] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 lies in that: the snow removal plate 10 is provided with a cavity 12, and the cavity 12 is provided with a heating coil 13, and the snow removal plate 10 is made of a heat-conducting material.

[0025] In this embodiment, according to the principle of electromagnetic induction, when the closed coil moves to cut the magnetic induction line, an induced current is generated in the coil, and because there is a current passing through the power line, a magnetic field is formed outside the power line, and the snow removal plate 10 drives the heating coil 13 in the When the power line slides back and forth, the heating coil 13 cuts the magnetic induction line to generate an induced current and heat, which heats the snow removal plate 10 to melt the snow accumulated on the snow removal plate 10, further improving its snow removal effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com