A processing method for the M-shaped box-shaped steel structure joints

A processing method and steel structure technology, applied in the direction of metal processing equipment, manufacturing tools, welding/welding/cutting items, etc., can solve the problem of difficulty in ensuring the quality of the joints of the rice-shaped box-shaped steel structure, the quality of the weld seam, and the welding operation Solve problems such as narrow space, achieve the effect of facilitating welding operation, reducing overall welding deformation and improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

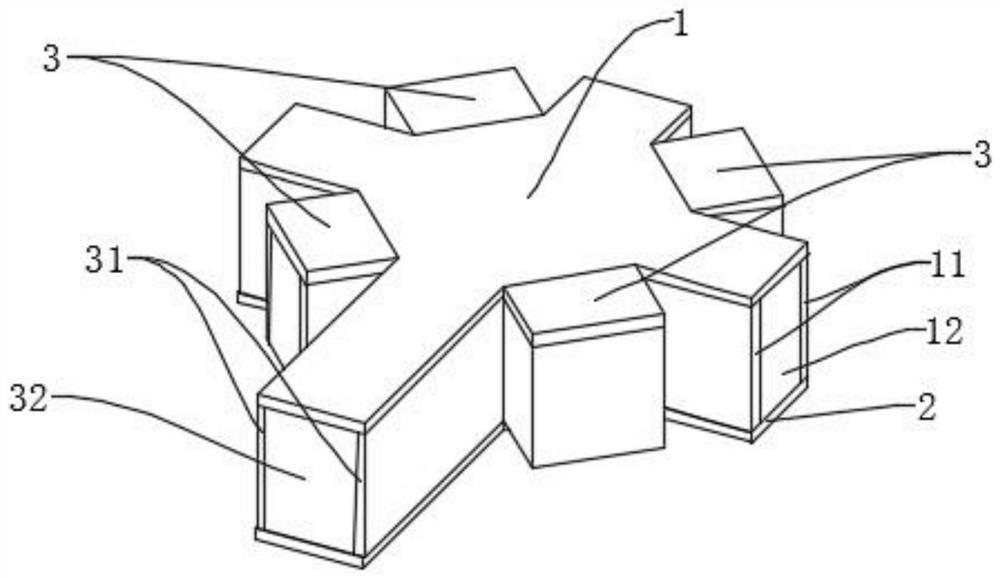

[0084] The invention provides a method for processing a M-shaped box-shaped steel structure node, comprising the following steps:

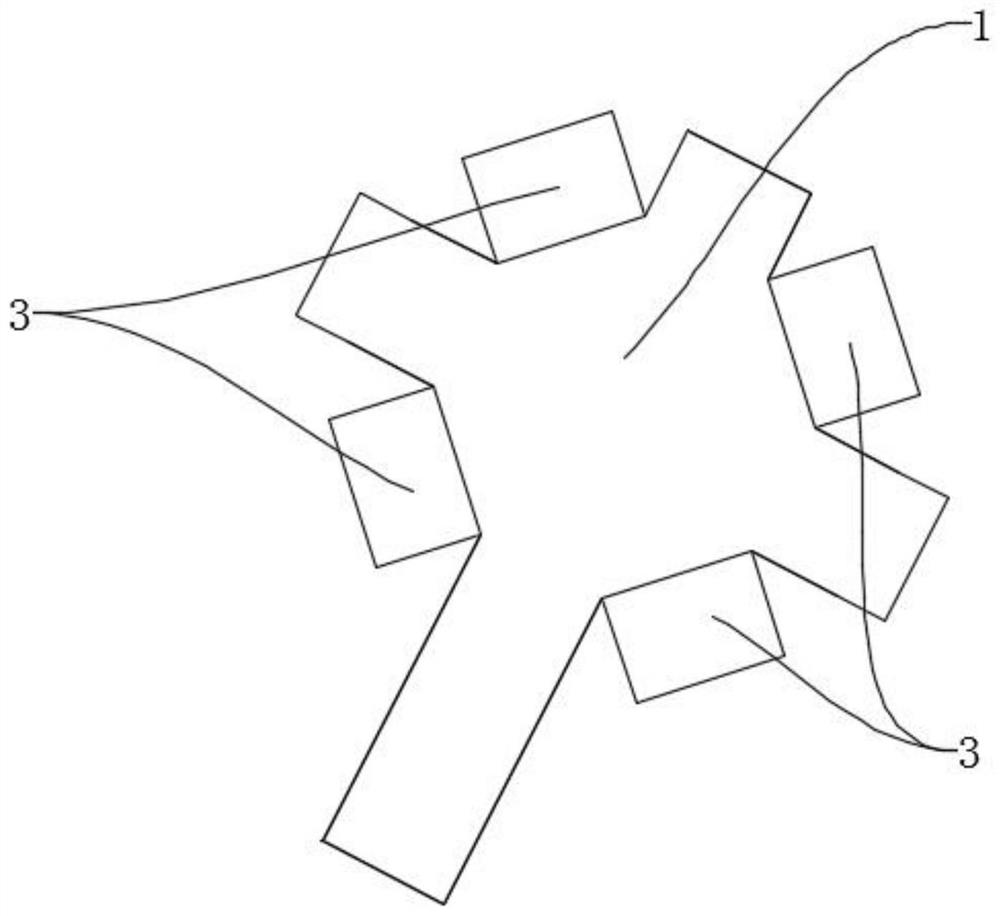

[0085] a: Install support rods to form a tire frame; in this embodiment, draw a projection line corresponding to the deepening dot pattern on the horizontal platform according to the deepening dot pattern, and then mark several sample punches according to the projection line eye, and finally place support rods at all the punch holes to set up the tire frame, which is used to place the lower wing plate 1;

[0086] b: Bending the upper wing plate 2 and the lower wing plate 1 respectively; in this embodiment, in order to meet the space modeling requirements of the special-shaped curved surface of the steel structure roof, the ports of the steel members all have torsion sections, so the M-shaped box The steel structure node also needs to correspond to the bending angle of the steel structure, and the bending angle refers to the bending angle, so the l...

Embodiment 2

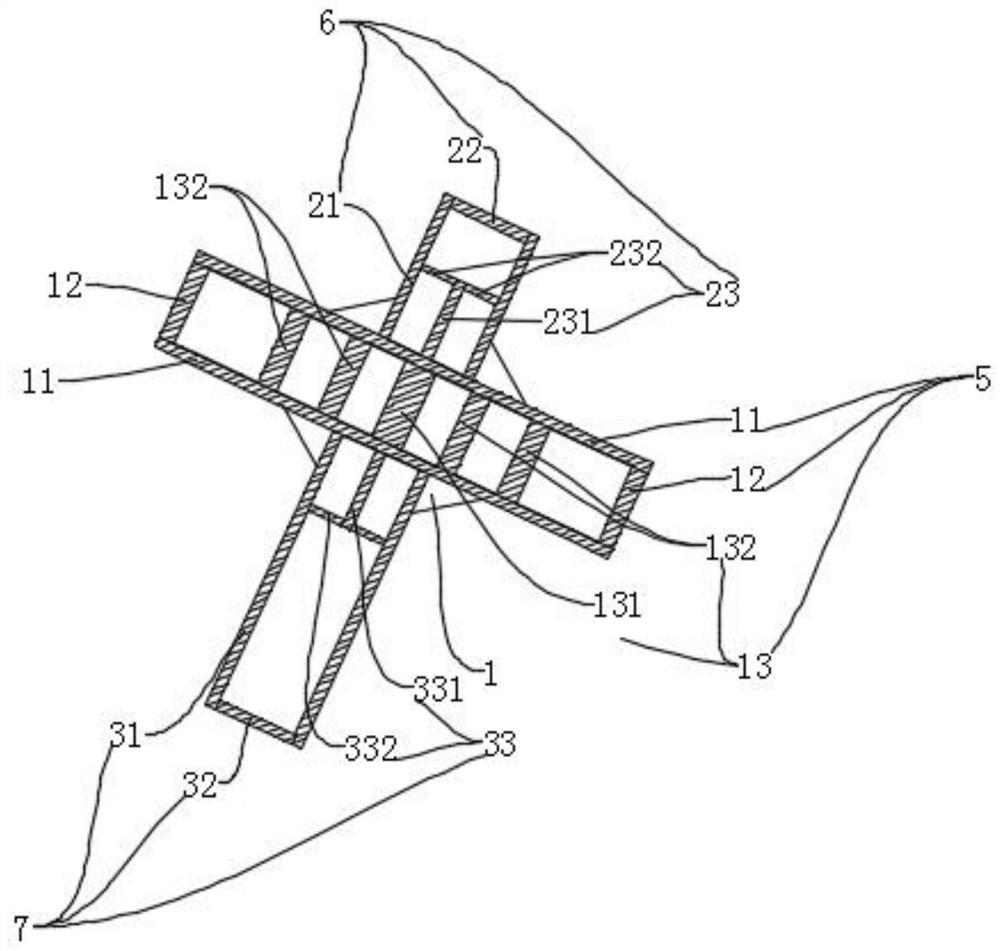

[0097] This embodiment provides a method for processing a M-shaped box-shaped steel structure node, which is different from Embodiment 1 in that the steps c-f can be replaced by the following steps as a whole:

[0098] c': Weld all the first inner partitions 13, the first web 11 close to the third main frame 7, and the third middle plate 331 on the lower wing 1 respectively, and then The upper wing plate 2 is welded to the top of all the installed first inner partitions 13, the first web 11 close to the third main frame 7, and the third middle plate 331. end face;

[0099] d': welding all the third webs 31 and all the first sealing plates 12;

[0100] e': welding the first web 11 close to the second main frame 6;

[0101] f': Weld the second middle plate 231, and then weld all the second webs 21.

[0102] The size of the second main frame 6 and the third main frame 7 of the M-shaped box-shaped steel structure node can be selected according to the construction requirements. ...

Embodiment 3

[0104] This embodiment provides a processing method for a P-shaped box-shaped steel structure node, which is consistent with Embodiment 1 as a whole, and is a detailed step of the processing method for a P-shaped box-shaped steel structure node described in Embodiment 1, including the following step:

[0105] a: Install support rods to form a tire frame; in this embodiment, draw a projection line corresponding to the deepening dot pattern on the horizontal platform according to the deepening dot pattern, and then mark several sample punches according to the projection line eye, and finally place support rods at all the punch holes to set up a tire frame, and the tire frame is used to place the lower wing plate 1;

[0106] b: Bending the upper wing plate 2 and the lower wing plate 1 respectively. In this embodiment, in order to meet the space modeling requirements of the special-shaped curved surface of the steel structure roof, the ports of the steel members all have torsion s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com