Feeding mechanism based on screw machine tool

A technology of feeding mechanism and processing machine tool, which is applied in the direction of metal processing, etc. It can solve the problems of unstable connection between feeding rail and vibrating plate, shaking of feeding rail, support of feeding rail, etc., and achieves the advantages of easy adjustment, increased support force, and reduced rotation difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

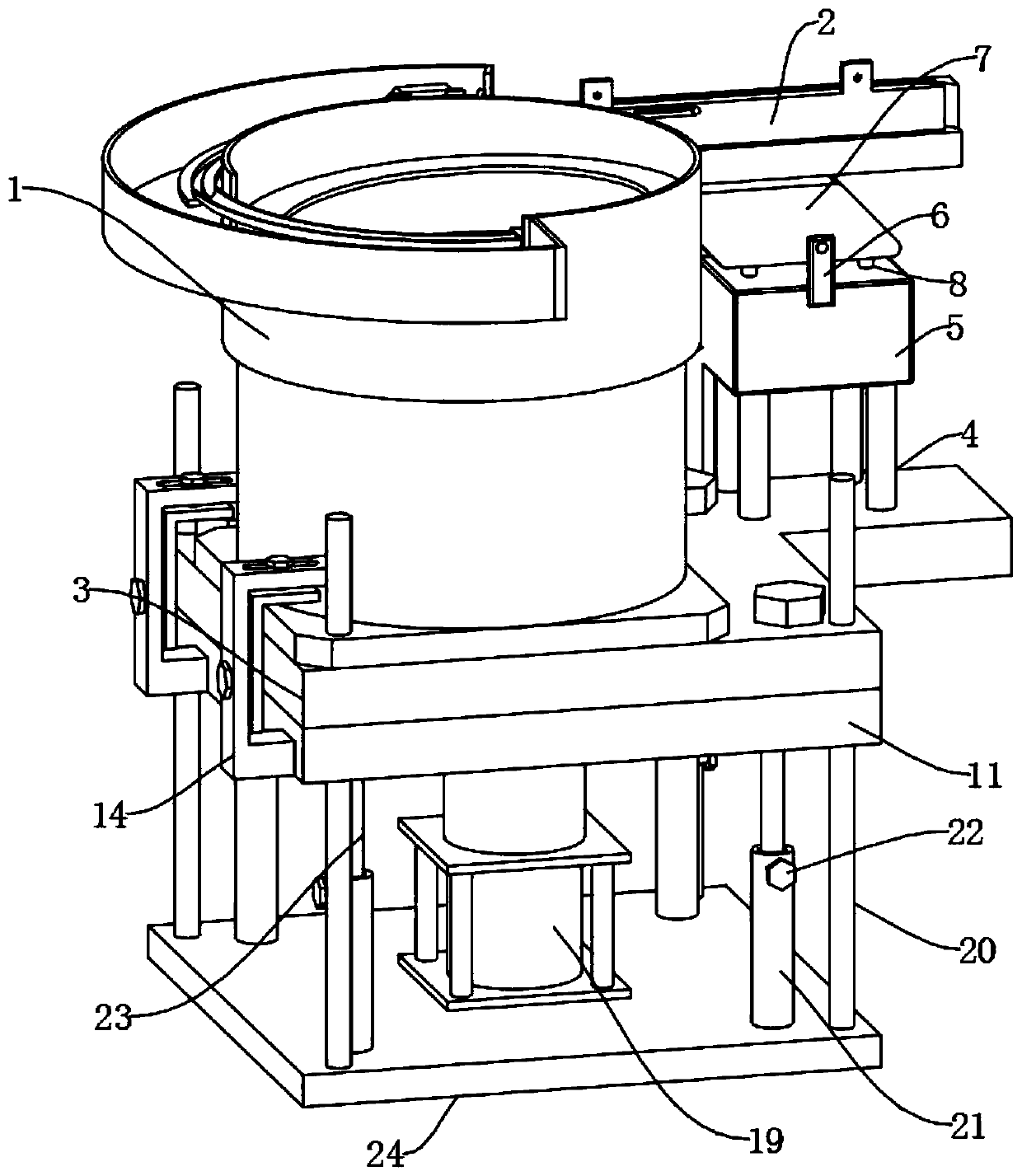

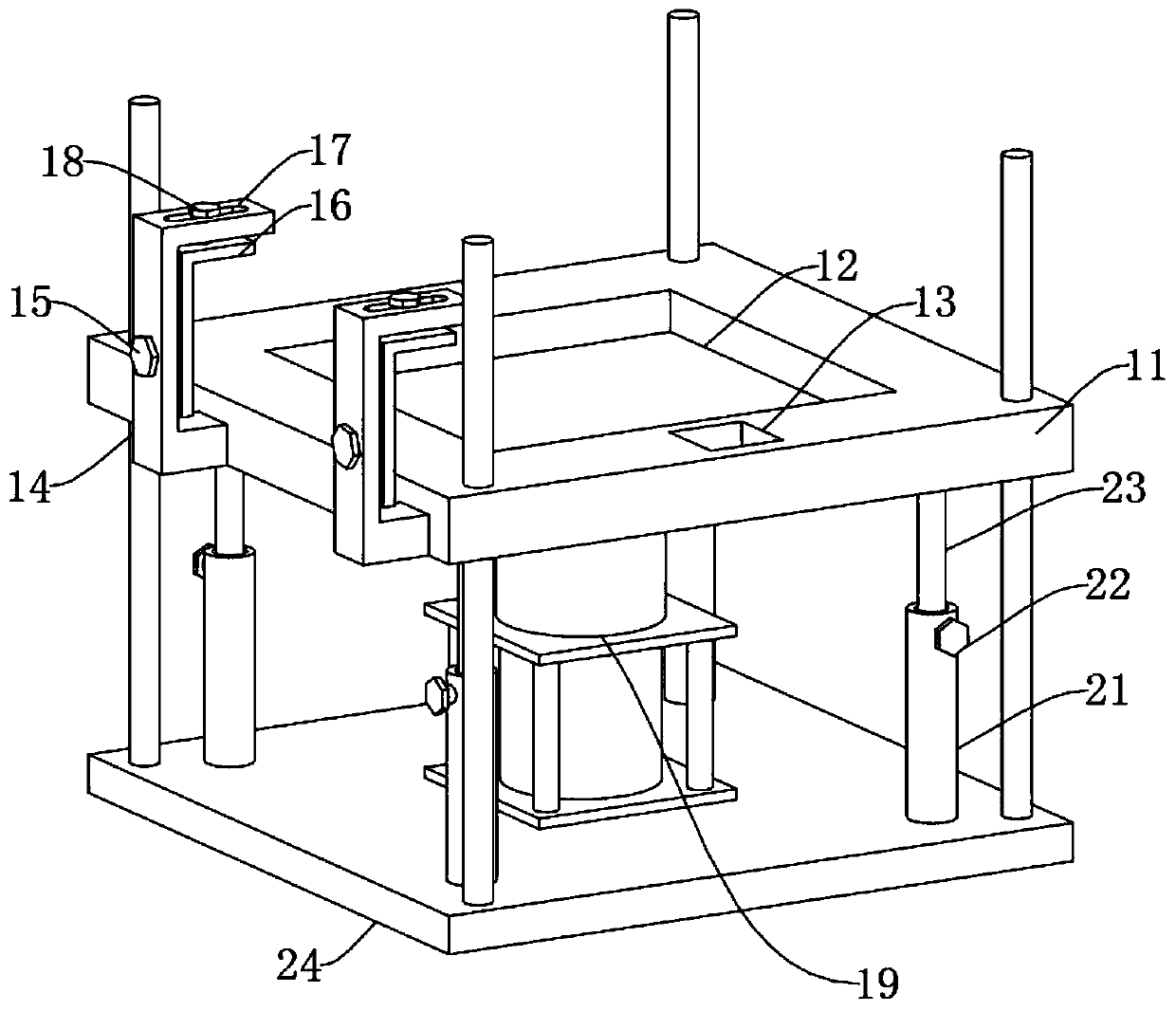

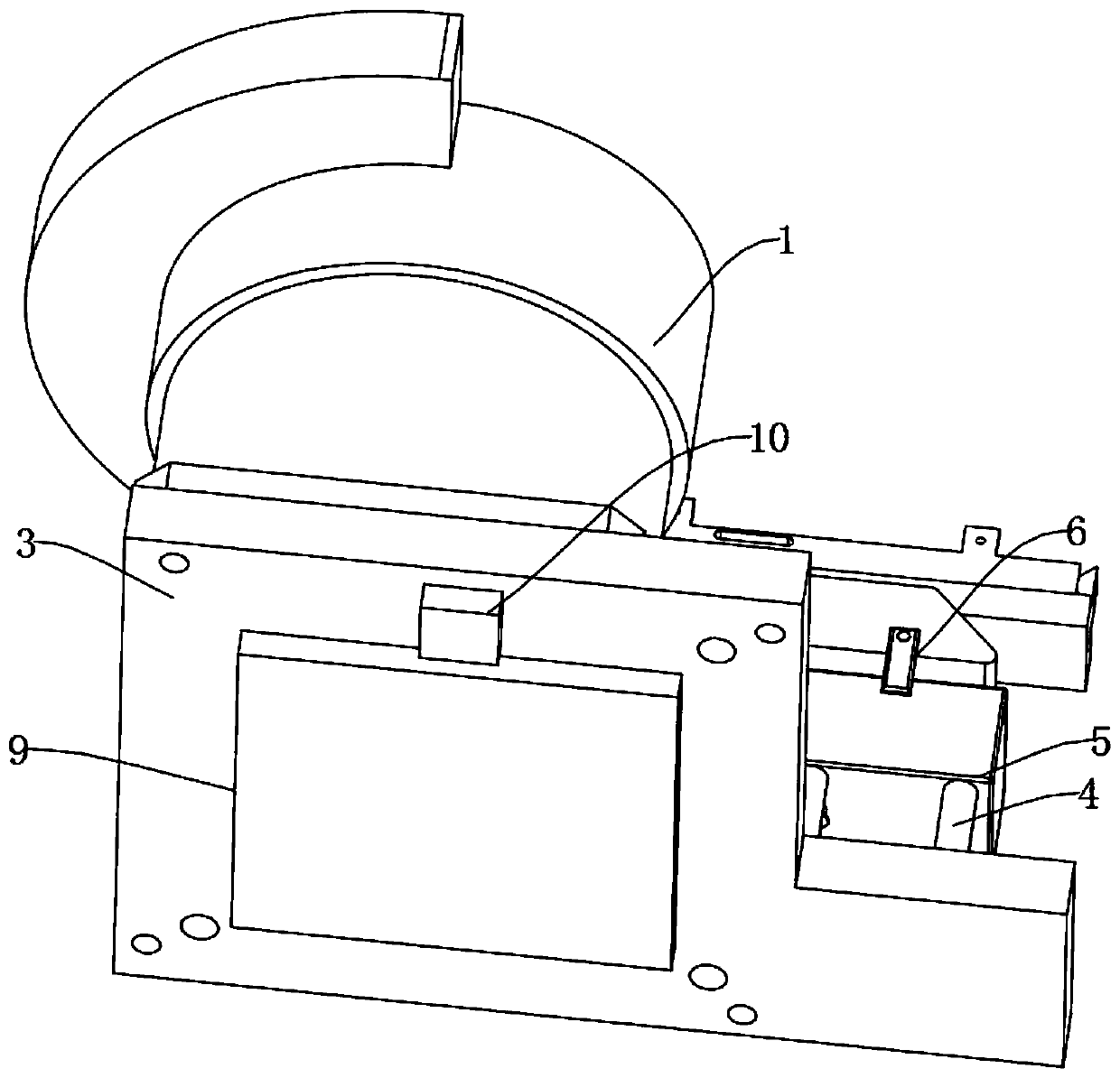

[0024] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a feeding mechanism based on a screw processing machine tool, including a feeding mechanism body 1 and a feeding track 2, the top side of the feeding mechanism body 1 is connected to the feeding track 2, and the feeding mechanism body 1 The bottom edge is connected with the bottom plate 3, the top side of the bottom plate 3 is welded with a support column 4, the middle part of the top of the support column 4 is welded with a support block 5, the front and back middle of the support block 5 are welded with a connecting plate 6, and the middle part of the inner wall of the connecting plate 6 The rotation is connected with a rotating block 7, the top of the rotating block 7 and the bottom edge of the feeding track 2 are attached to each other, and the overlapping connection between the feeding track 2 and the feeding mechanism body 1 can facilitate the adjustment of the angle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com