A method for producing r243, r244 and r245 by pipeline polygeneration by liquid phase method

A pipeline and polygeneration technology, applied in chemical instruments and methods, organic chemistry, dehydrohalogenation preparation, etc., can solve the problems of high energy consumption, corroded reactors, high equipment cost, etc., to simplify equipment process, increase transmission Quality, to achieve the effect of continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

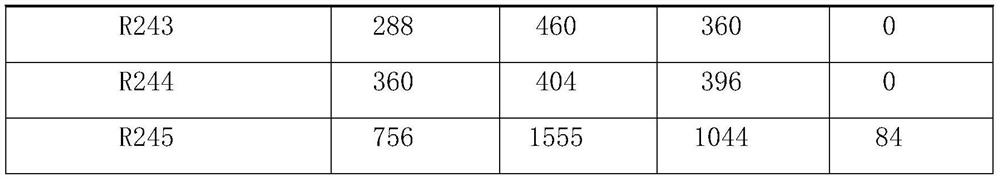

Embodiment 1

[0034] 1. a method for the production of R243, R244 and R245 by liquid-phase pipeline polygeneration, characterized in that,

[0035] The method comprises the steps of:

[0036] (1) The raw material is pumped in from the inlet of the pipeline reactor, and the pipeline reactor includes a heating section group and a cooling section group, and the raw material includes 1,1,1,3,3-pentachloropropane, hydrogen fluoride and A fluorination catalyst, the raw materials are mixed into a reaction solution in a pipeline reactor, so that in the presence of the fluorination catalyst, 1,1,1,3,3-pentachloropropane and hydrogen fluoride are mixed in the pipeline reactor Contacting, thereby carrying out fluorination reaction, obtains the reaction liquid flow that comprises R243, R244 and R245;

[0037] (2) From the reaction liquid flow of step (1), separate out part R243 and R244 successively, after forming R243 product flow and R244 product flow, remaining reaction liquid flow continues to carry...

Embodiment 2

[0048] The difference between embodiment 2 and embodiment 1 is that, in the pipeline reactor of embodiment 2, hydrogen fluoride is supplemented into the pipeline reactor from the front end of the heating section group, so that there is enough hydrogen fluoride to make step (1) And (2) the molar ratio of hydrogen fluoride to R243 is at least 20:1, and the molar ratio of hydrogen fluoride to R244 is at least 20:1; Effect is to keep the concentration of hydrogen fluoride in the reaction solution, prevent the concentration of hydrogen fluoride in the reaction solution from being too high on the one hand. High side reactions will also corrode the pipes of the piped reactor. On the other hand, keep the concentration of hydrogen fluoride in the reaction solution in the normal range to prevent the concentration of hydrogen fluoride in the reaction solution from being too low to affect the fluorination reaction speed. For other relevant technical features not listed in Embodiment 2, ref...

Embodiment 3

[0059] Embodiment 3, the difference from Embodiment 1 and Embodiment 2 is that before the liquid phase material of Embodiment 3 is pumped back to the pipelined reactor, the solid matter in the liquid phase material is filtered out through a filtering device; Further, transfer the solid matter to the fluorination catalyst reactivation equipment for reactivation to obtain the reactivated fluorination catalyst, and pump it back to the pipeline reactor, the function is to keep the reaction liquid fluorination catalyst concentration, so as to ensure the speed of fluorination reaction. For other relevant technical features not listed in Embodiment 3, refer to Embodiment 1 or Embodiment 2.

[0060] A method for the production of R243, R244 and R245 by pipeline polygeneration in a liquid phase method,

[0061] (1) The raw material is pumped in from the inlet of the pipeline reactor, and the pipeline reactor includes a heating section group and a cooling section group, and the raw mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com