Preparation method of propylene glycol polyoxypropylene ether

A technology of propylene glycol polyoxypropylene ether and propylene glycol, which is applied in the field of preparation of polyoxypropylene ether, can solve the problems of difficulty in increasing the molecular weight, increase of unsaturation, poor refining effect, etc., and achieve small molecular weight distribution coefficient and narrow molecular weight distribution , good viscosity controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

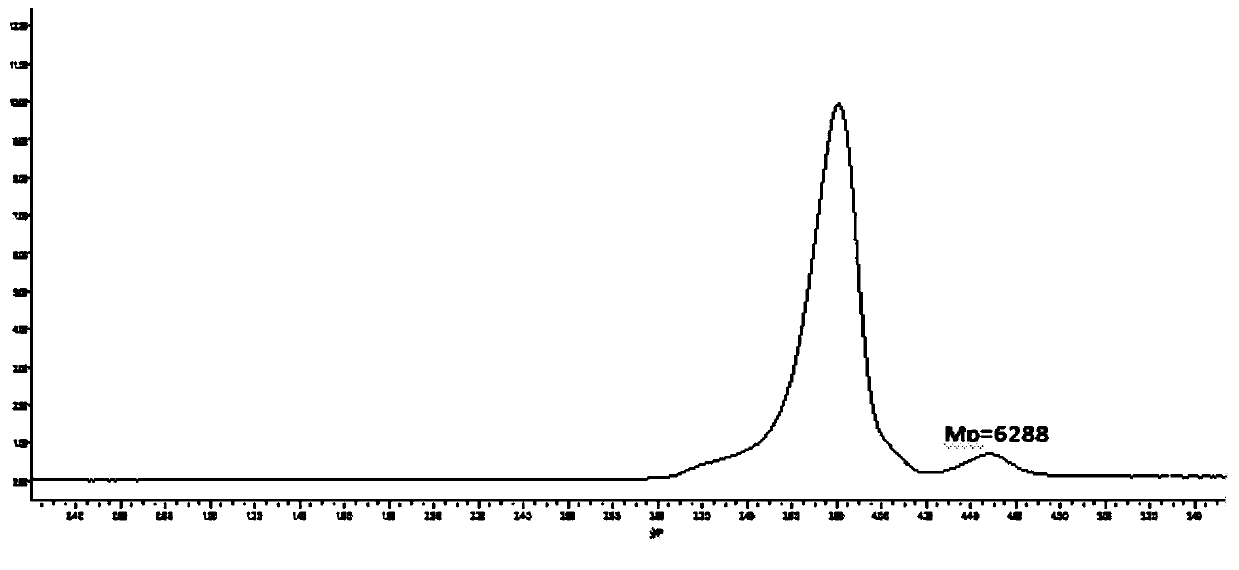

Image

Examples

Embodiment 1

[0026] A kind of preparation method of propylene glycol polyoxypropylene ether, comprises the steps:

[0027] S1: Add 200g of anhydrous propylene glycol to the reactor, BF 3 4.6g and 1.22g deionized water, pass N 2 After completely replacing the air in the closed reactor, close the reactor and then raise the temperature;

[0028] S2: Put 1129g of propylene oxide into the reaction kettle, and continue to heat up, wait until the temperature in the reaction kettle rises to 70°C, keep warm and carry out the reaction, until the pressure in the reaction kettle drops to the point where it cannot be lowered;

[0029] S3: Connect the vacuum pump to the reactor, turn on the vacuum pump to evacuate, remove the low boilers in the reactor, and obtain the propylene glycol oligomer intermediate.

[0030] S4: In another reactor, add 500g of the propylene glycol oligomer intermediate that S2 makes, DMC catalyst 0.08g, logical N 2 Replace the air in the reactor until the vacuum in the react...

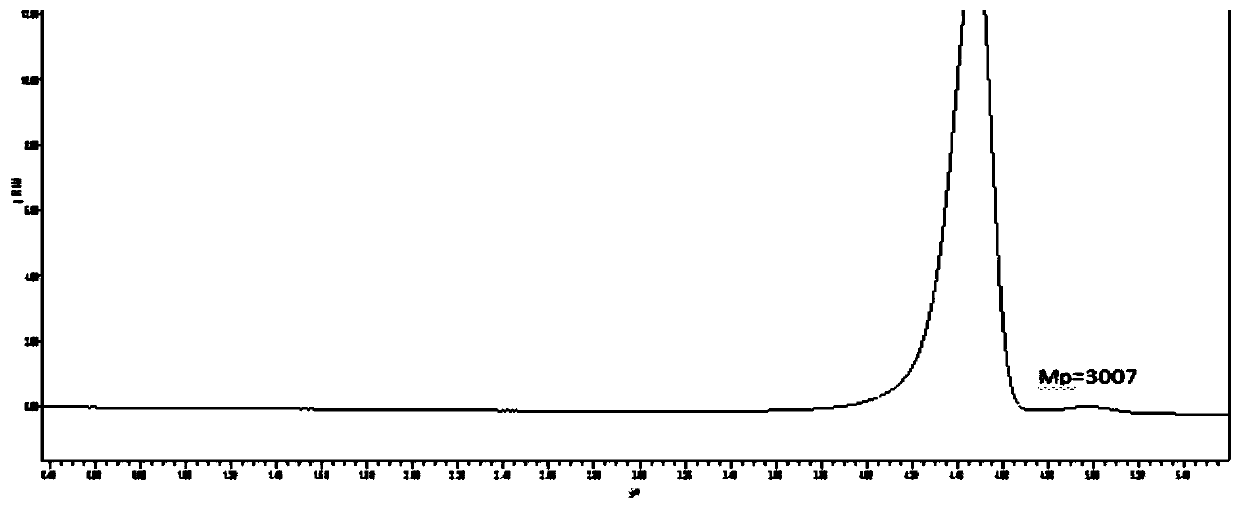

Embodiment 2

[0032] A preparation method of propylene glycol polyoxypropylene ether, comprising the following steps:

[0033] S1: Add 200g of anhydrous propylene glycol and BF to the reactor 3 1.8g, through N 2 After completely replacing the air in the closed reactor, close the reactor and then raise the temperature;

[0034] S2: Put 1642g of propylene oxide into the reaction kettle, and continue to heat up, wait until the temperature in the reaction kettle rises to 70°C, keep warm for the reaction, and wait until the pressure in the reaction kettle drops to the point where it cannot be lowered;

[0035] S3: Connect the vacuum pump to the reactor, turn on the vacuum pump to evacuate, remove the low boilers in the reactor, and obtain the propylene glycol oligomer intermediate.

[0036] S4: In another reactor, add 700g of propylene glycol oligomer intermediate that S2 makes, DMC catalyst 0.10g, logical N 2 Replace the air in the reactor until the vacuum in the reactor is ≤-0.095MPa, clos...

Embodiment 3

[0038] A preparation method of propylene glycol polyoxypropylene ether, comprising the following steps:

[0039] S1: Add 200g of anhydrous propylene glycol, SbCl 5 3.7g and Ph 3 CCl 3.5g, through N 2 After completely replacing the air in the closed reactor, close the reactor and then raise the temperature;

[0040] S2: Put 1642g of propylene oxide into the reaction kettle, and continue to heat up, wait until the temperature in the reaction kettle rises to 30°C, keep warm and carry out the reaction, until the pressure in the reaction kettle drops to the point where it cannot be lowered;

[0041] S3: Connect the vacuum pump to the reactor, turn on the vacuum pump to evacuate, remove the low boilers in the reactor, and obtain the propylene glycol oligomer intermediate.

[0042] S4: In another reactor, add 500g of the propylene glycol oligomer intermediate that S2 makes, DMC catalyst 0.13g, logical N 2 Replace the air in the reactor until the vacuum in the reactor is ≤-0.095M...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap