Vat olive T liquid dye and production process

A technology of liquid dye and production process, which is applied in the field of reduced olive T liquid dye and production process, which can solve the problems of low production efficiency, inconvenient use, and large pollution, and achieve the effects of saving energy, reducing COD value, and reducing dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A vat olive T liquid dye, the formula includes: benzothrone, 1-aminoanthraquinone, soda ash, dispersant, anti-coagulation aid and water, and the mass percentages of each component are: benzoxantrone 18 %, 25% of 1-aminoanthraquinone, 1% of soda ash, 0.1% of dispersant, 0.1% of anti-coagulation aid and 55.8% of water.

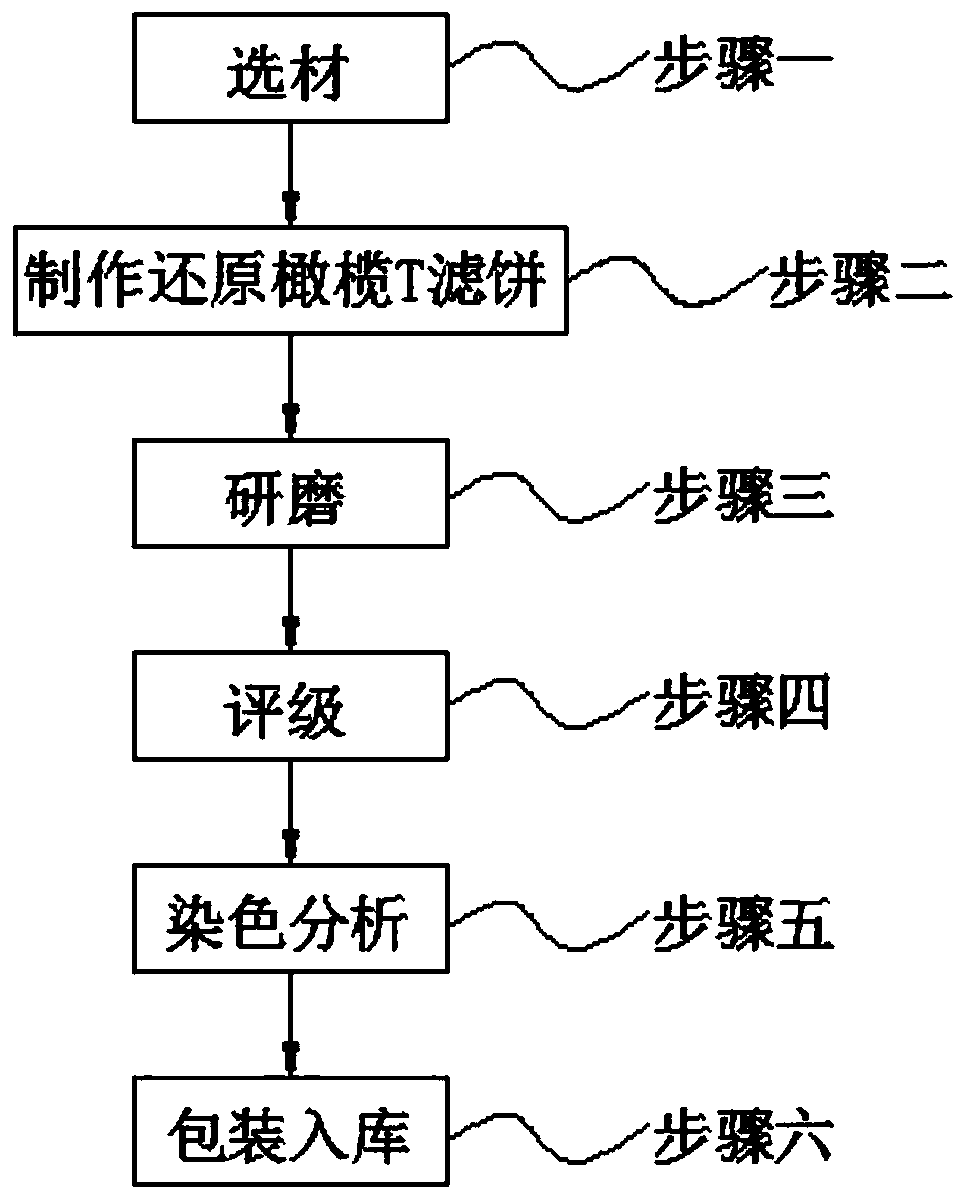

[0023] A manufacturing process of reduced olive T liquid dye, comprising the following steps, step 1, material selection; step 2, making reduced olive T filter cake; step 3, grinding; step 4, grading; step 5, dyeing analysis; step 6, packaging Storage;

[0024] Wherein the above-mentioned step 1, according to the mass percentage content of each component is respectively: 18% of benzoantrone, 25% of 1-aminoanthraquinone, 1% of soda ash, 0.1% of dispersant, 0.1% of anti-coagulation aid and water 55.8% weighed;

[0025] In the above step two, first add the benzoantrone, 1-aminoanthraquinone and soda ash weighed in the step 1 to the stirred reactor with sea...

Embodiment 2

[0031] A vat olive T liquid dye, the formula includes: benzothrone, 1-aminoanthraquinone, soda ash, dispersant, anti-coagulation aid and water, and the mass percentages of each component are: benzoxantrone 20 %, 1-aminoanthraquinone 20%, soda ash 3%, dispersant 0.5%, anti-coagulation aid 0.5% and water 56%.

[0032] A manufacturing process of reduced olive T liquid dye, comprising the following steps, step 1, material selection; step 2, making reduced olive T filter cake; step 3, grinding; step 4, grading; step 5, dyeing analysis; step 6, packaging Storage;

[0033] Wherein in the above step 1, according to the mass percentage of each component, they are: 20% benzoantrone, 20% 1-aminoanthraquinone, 3% soda ash, 0.5% dispersant, 0.5% anti-coagulation aid and water 56% weighed;

[0034] In the above step two, first add the benzoantrone, 1-aminoanthraquinone and soda ash weighed in the step 1 to the stirred reactor with sealing function, brominate the benzoantrone, and then mix...

Embodiment 3

[0040] A vat olive T liquid dye, the formula includes: benzothrone, 1-aminoanthraquinone, soda ash, dispersant, anti-coagulation aid and water, and the mass percentages of each component are: benzoxantrone 23 %, 20% of 1-aminoanthraquinone, 5% of soda ash, 1% of dispersant, 1% of anti-coagulation aid and 50% of water.

[0041] A manufacturing process of reduced olive T liquid dye, comprising the following steps, step 1, material selection; step 2, making reduced olive T filter cake; step 3, grinding; step 4, grading; step 5, dyeing analysis; step 6, packaging Storage;

[0042] Wherein in the above step 1, according to the mass percentage of each component, they are: 23% benzoantrone, 20% 1-aminoanthraquinone, 5% soda ash, 1% dispersant, 1% anti-agglomeration aid and water 50% weighed;

[0043] In the above step two, first add the benzoantrone, 1-aminoanthraquinone and soda ash weighed in the step 1 to the stirred reactor with sealing function, brominate the benzoantrone, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com