Method for determining critical desorption pressure of coal bed gas

A critical desorption and coalbed methane technology, which is applied in earthwork drilling, wellbore/well components, measurement, etc., can solve the problems that have not been considered, and have not considered the extra pressure drop and consumption of nanopore desorption gas production, and achieve the goal of optimizing the development plan Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in combination with specific embodiments.

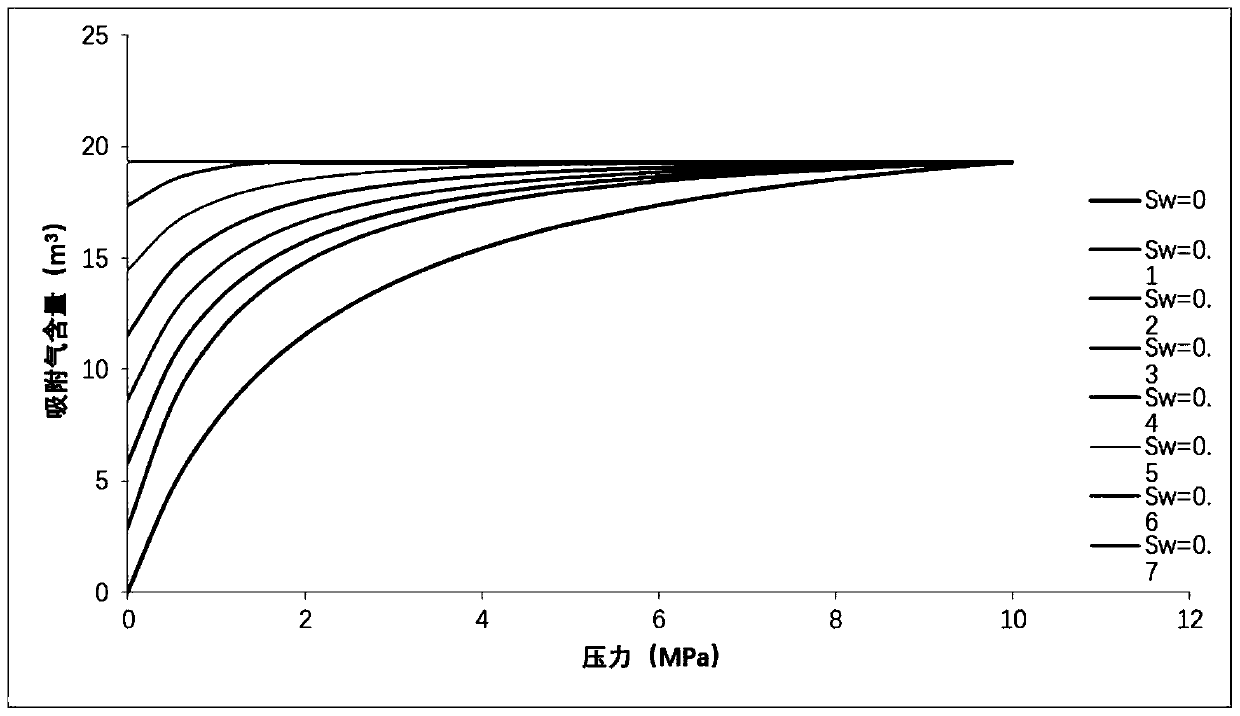

[0048] The technical concept of the present invention includes: According to the process of methane production in coal reservoirs, it can be divided into three stages: the stage of desorption of methane gas from the matrix, the stage of channeling from matrix pores to cleats, and the stage of channeling from cleats to fracturing fractures / wellbore. West seepage stage; determine the desorption curve considering the influence of water according to the first stage, and then determine the corrected desorption pressure after considering the pressure drop of the second and third stages respectively.

[0049] The embodiment of the present invention discloses a method for determining the critical desorption pressure of a coalbed methane well, including the following steps:

[0050] Step 1. Collect and test the basic parameters for calculating the critical desorption pressure of C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com