High-pressure water jet double-slit coupling rock breaking tunnel boring machine

A high-pressure water jet and roadheader technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of slow driving speed, accelerated hob wear rate, low hob penetration, etc., to achieve rapid construction, improve Longevity and wear-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In view of this, the core of the present invention is to disclose a high-pressure water jet double-slit coupling rock-breaking tunneling machine, which reduces the wear of the hob.

[0036] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

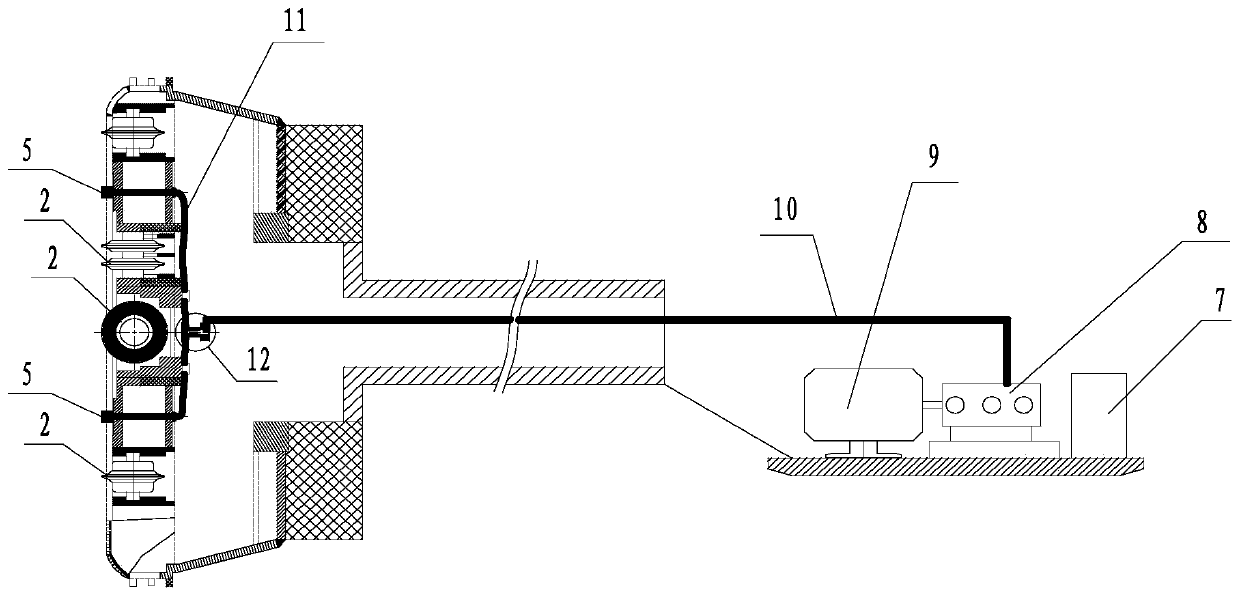

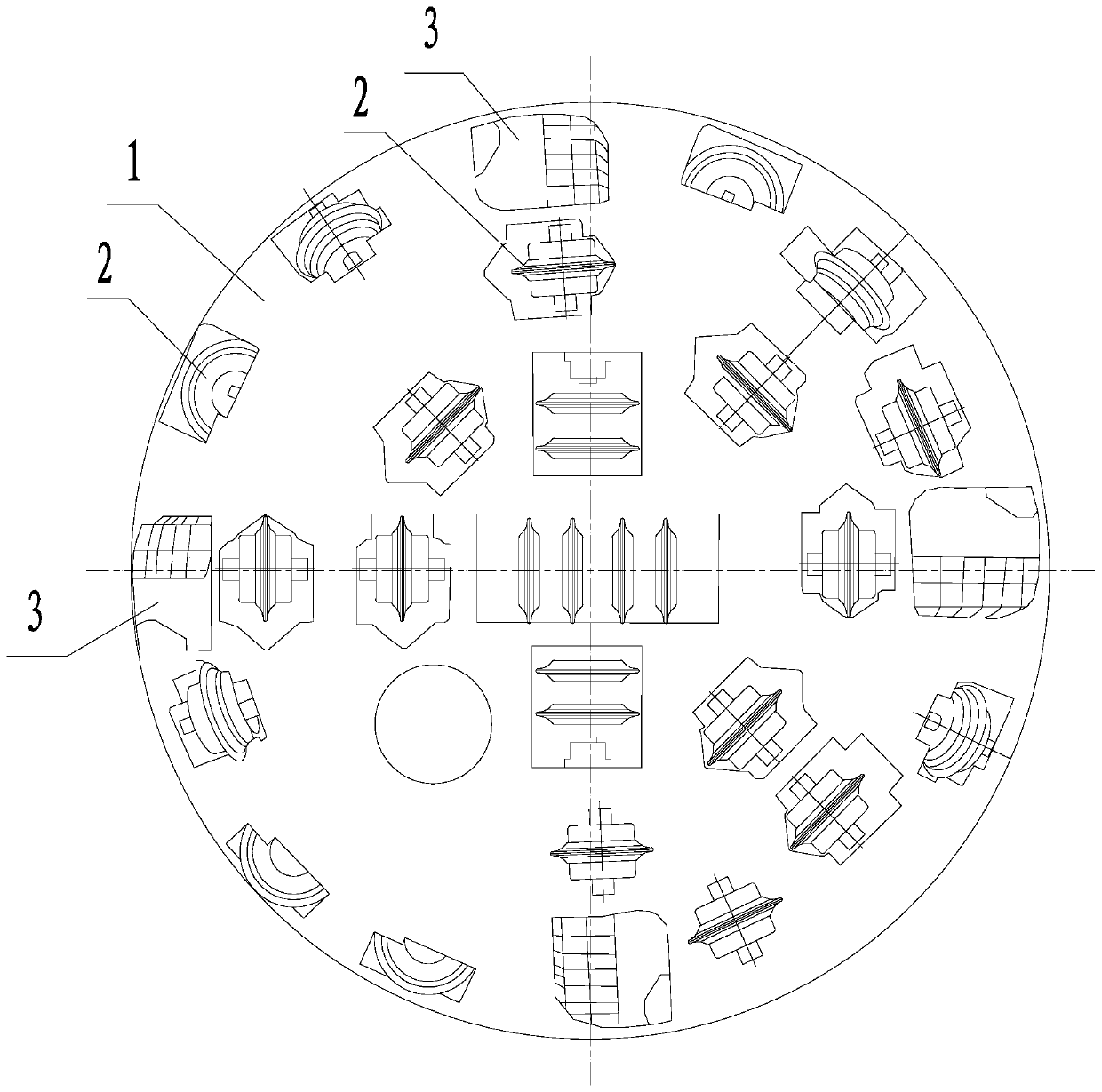

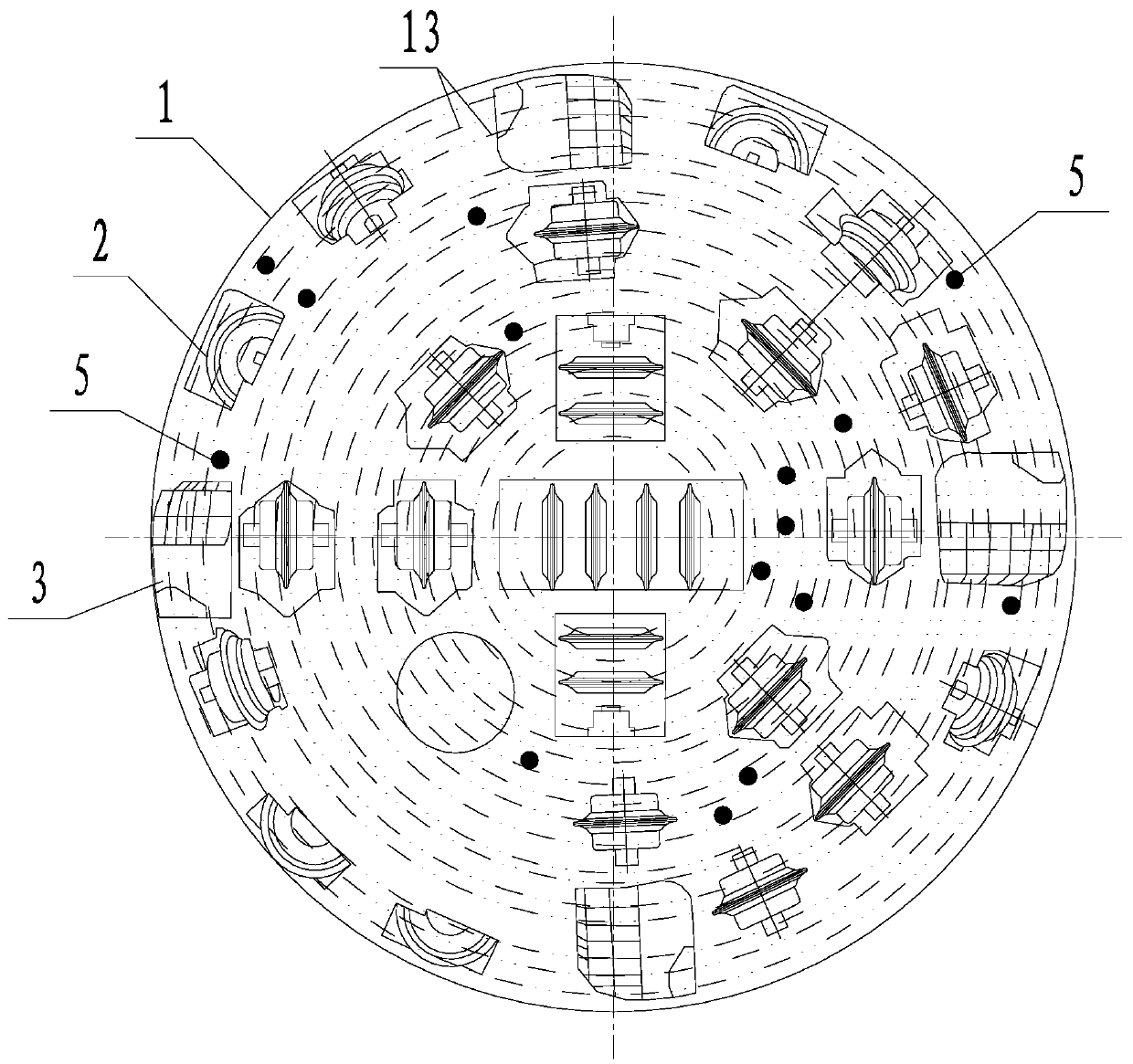

[0037] Such as Figure 1-Figure 5 As shown, the present invention discloses a high-pressure water jet double-slit coupled rock-breaking tunneling machine, which includes a cutter head 1, a spraying device and a high-pressure water generating device. Wherein, the hob 2 is installed on the first side of the cutterhead 1, and the hob 2 is a cutter for breaking rocks. In practice, multiple hobs 2 may be installed on the cutterhead 1, and the installation positions will be along the The circumferential arrangement of the disk 1; in order to reduce th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap