Piezoelectric plate driving nozzle baffle disc pressure servo valve with main valve element hydrodynamic force compensation function

A technology for driving nozzles and hydraulic power, applied in servo motor components, fluid pressure actuation devices, fluid pressure actuation system components, etc., can solve the problems of small displacement of piezoelectric plates and difficult large flow valve actuation mechanism, etc., to achieve Good linearity, avoid complex and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0042] This invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art. In the drawings, components are exaggerated for clarity.

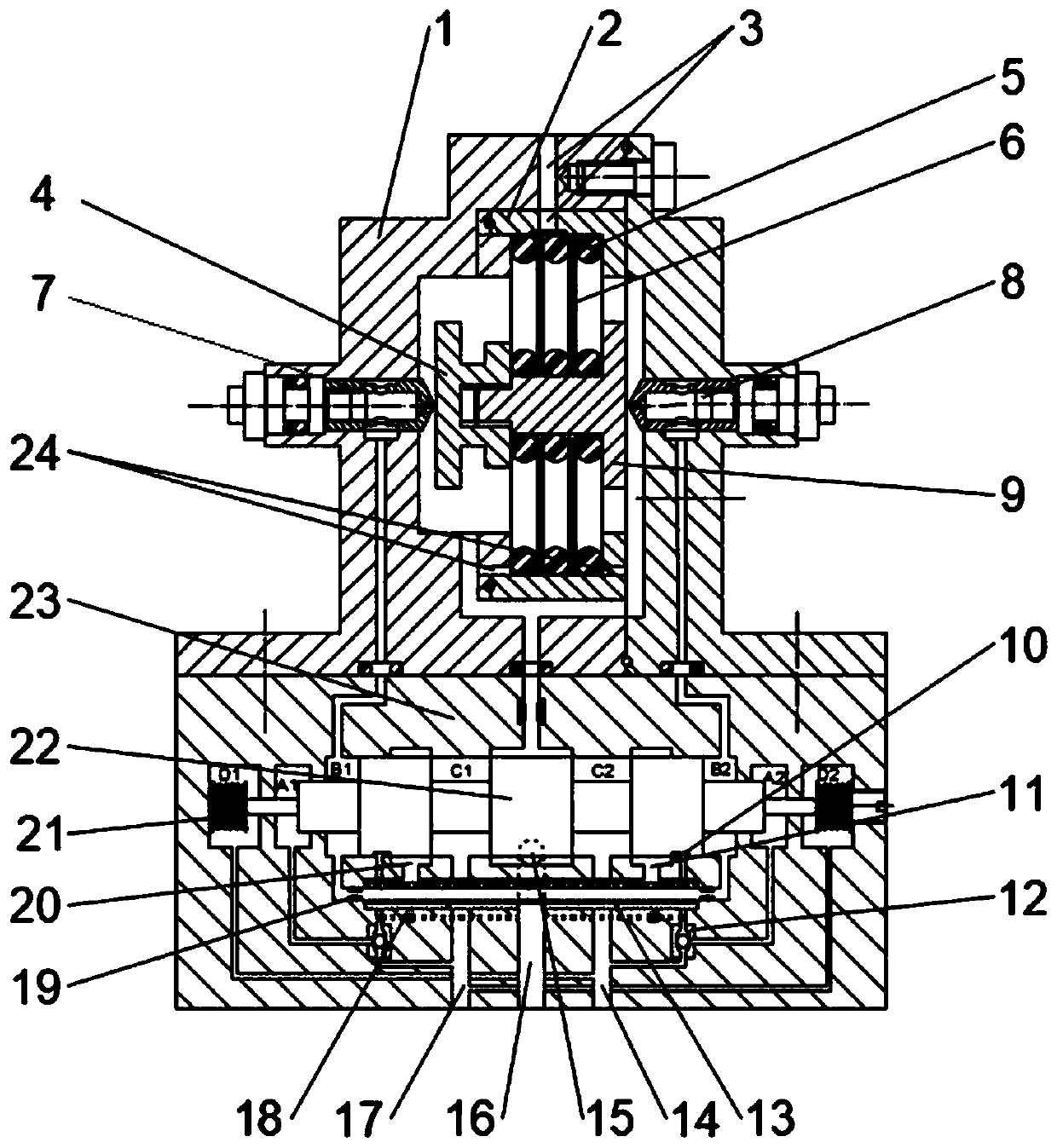

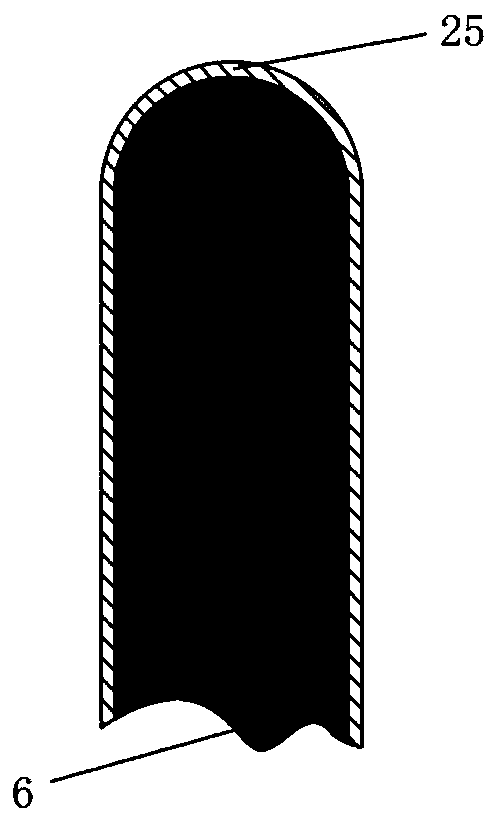

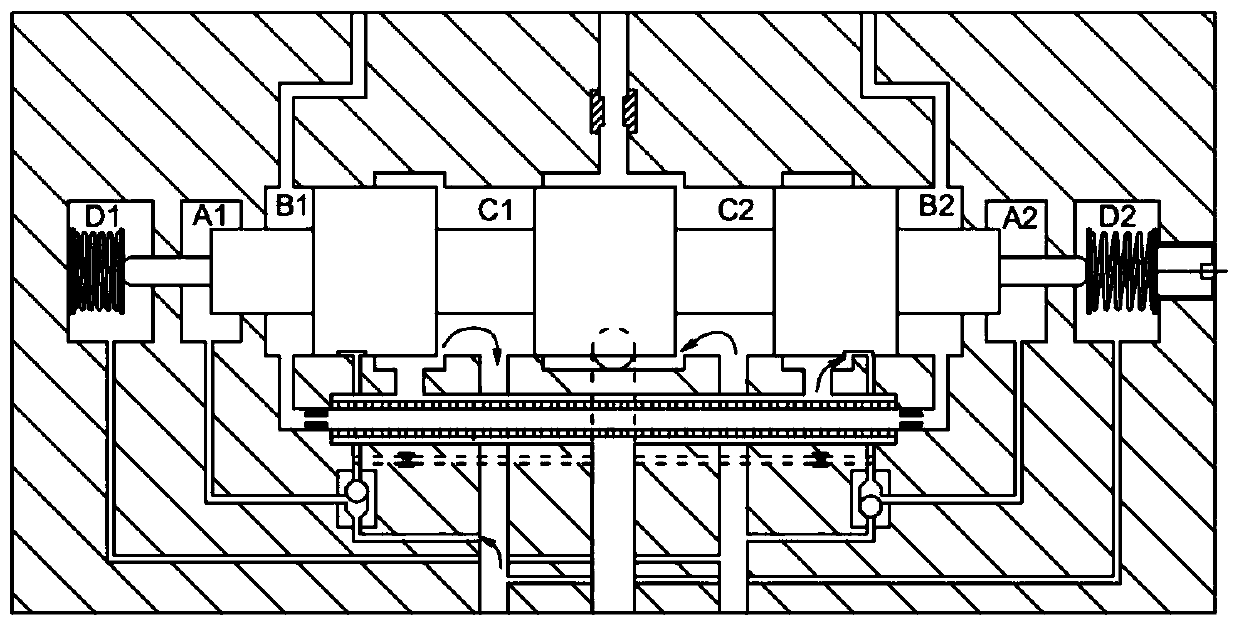

[0043] Such as figure 1 As shown, the present invention discloses a piezoelectric ring driven nozzle retainer pressure servo valve with hydrodynamic compensation of the main spool, including an upper casing, an adjustment assembly, a first nozzle, a second nozzle, a lower casing, and a spool , the first return spring, the second return spring, the oil filter, the first shuttle valve and the second shuttle valve;

[0044] The adjustment assembly includes a fixed cylinder, N annular pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com