Friction-resistant brake pad for high-speed train and preparation method thereof

A high-speed train, friction-resistant technology, applied in the direction of friction linings, mechanical equipment, gear transmission mechanisms, etc., can solve the problem that the friction heat cannot be quickly transmitted to the graphite layer and copper base, weaken the heat transfer rate of the wear-resistant layer, and affect the use Life and other issues, to achieve the effect of improving thermal conductivity, excellent wear resistance, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be described in further detail below in conjunction with the accompanying drawings.

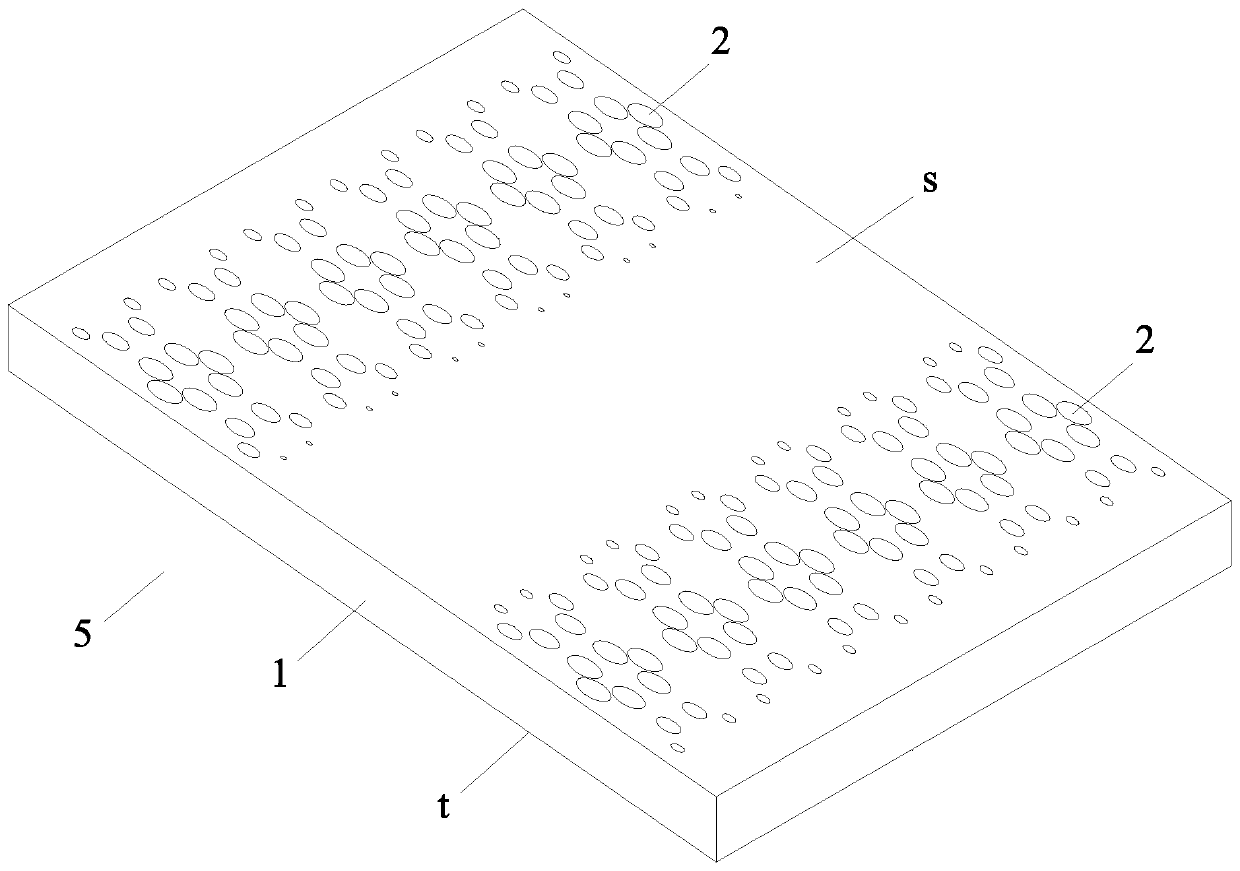

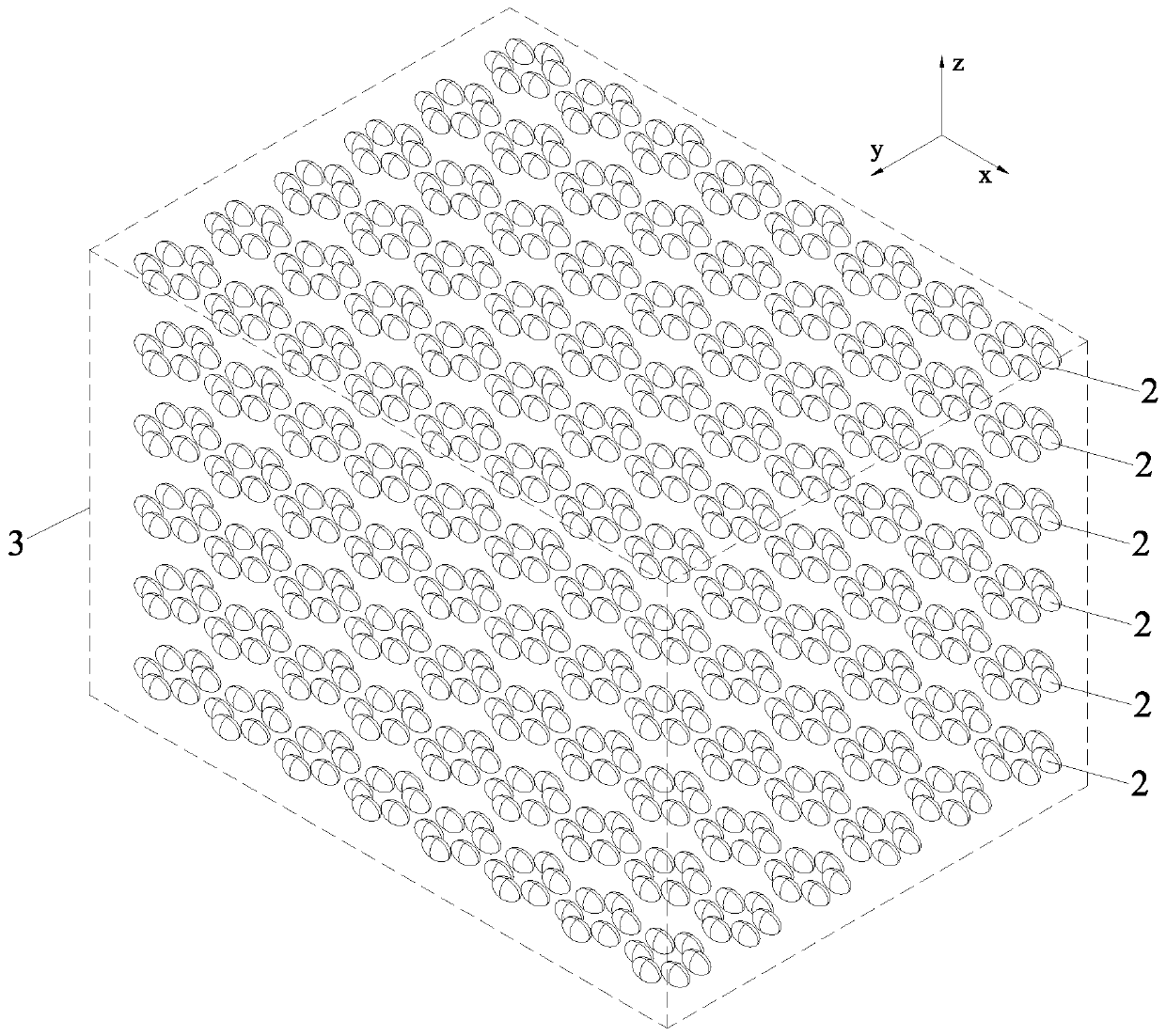

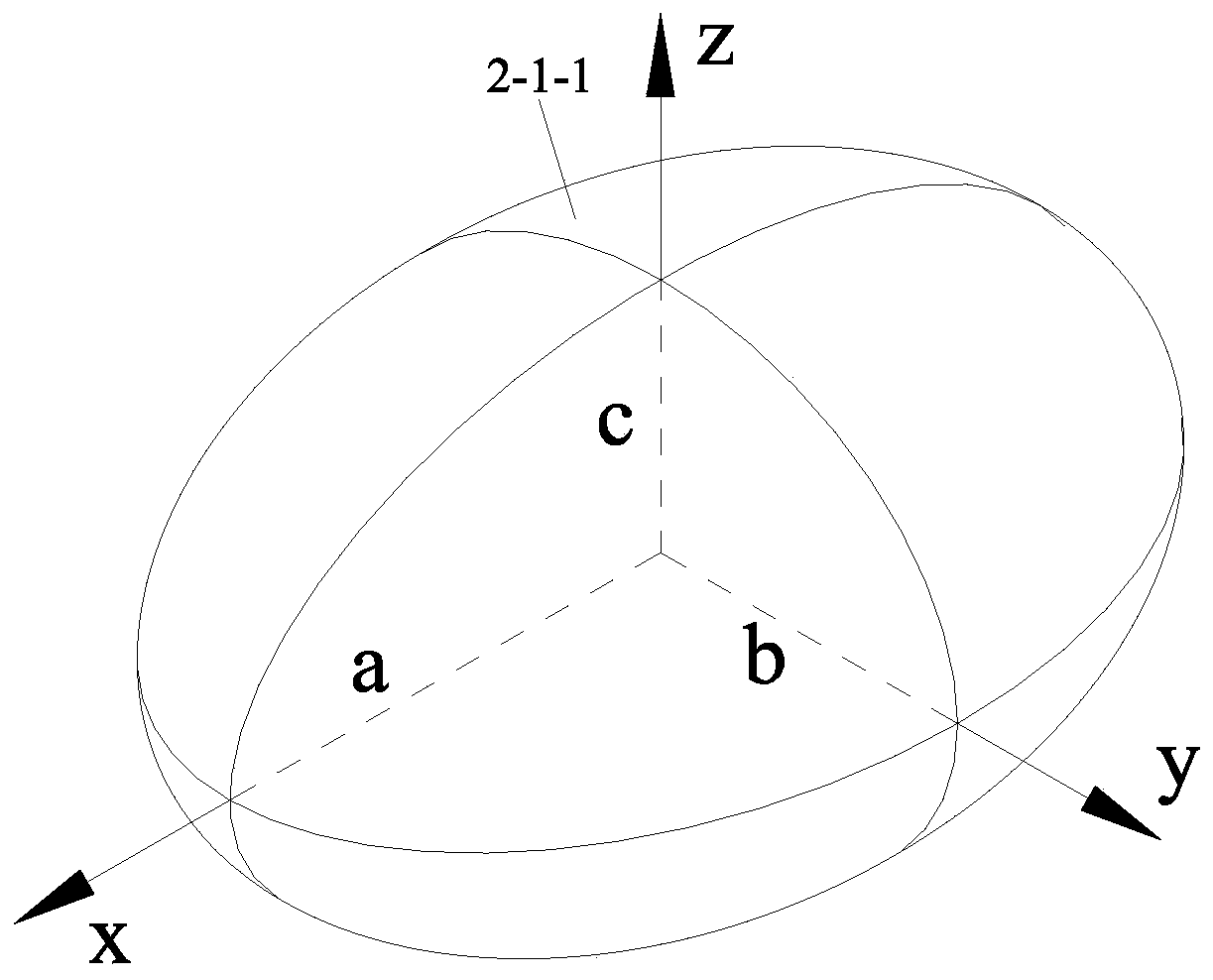

[0067] Such as Figure 1 to Figure 6 As shown, the anti-friction brake pad 5 of the present invention includes a base material lubricating heat conductor 1 and a plurality of wear-resistant body crystal block array layers 2 distributed therein, and a plurality of wear-resistant body crystal block array layers 2 are arranged at a distance H Arranged in layers, each wear-resistant crystal block array layer 2 is formed by a square array with a side length L of a plurality of hexagonal grinding ball agglomerates 2-1;

[0068] The substrate lubricated heat conductor 1 is cut from the substrate lubricated heat conductor rectangular prism blank 3, the upper and lower end surfaces of the substrate lubricated heat conductor 1 are the upper end surface s of the heat conductor and the lower end surface t of the heat conductor parallel to each other, and the wear-resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com