Simple calculation method for variable working condition performance of steam extraction heat supply type gas-steam combined cycle unit

A combined cycle unit, steam extraction and heat supply technology, applied in design optimization/simulation, etc., can solve problems such as difficult promotion, incompleteness, large amount of calculation, etc., and achieve the effect of easy promotion, less data, and simple calculation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

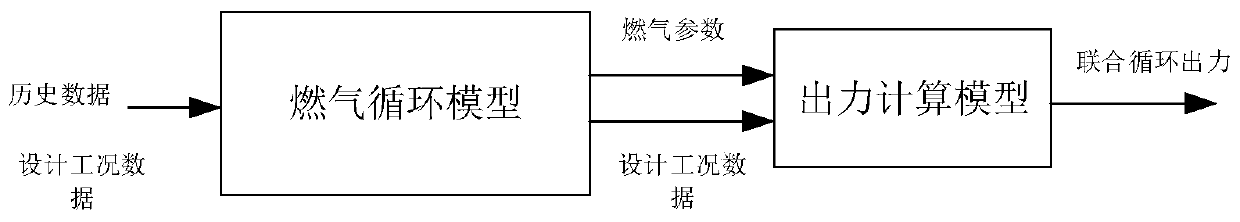

[0047] Such as figure 1 As shown, a simple calculation method for the variable working condition performance of a steam extraction heating type gas-steam combined cycle unit of the present invention comprises the following steps:

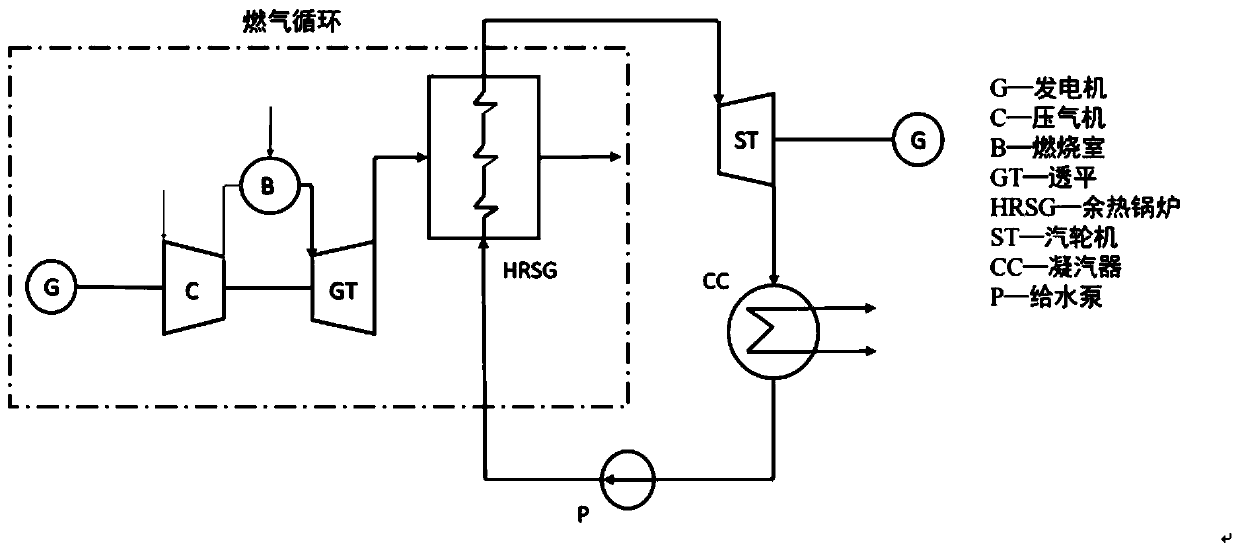

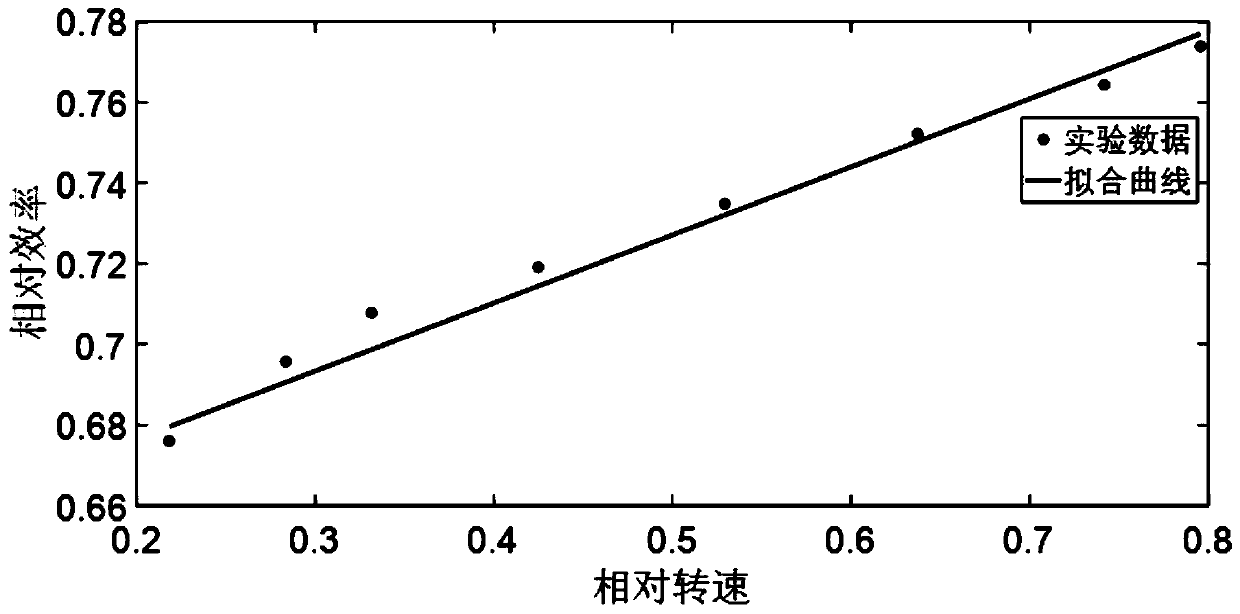

[0048] Step 1: Establish the gas cycle variable working condition model of the combined cycle unit. After the initial conditions (environment temperature, pressure, fuel volume) are given, the gas parameters (gas flow and temperature); as figure 2 As shown, the gas cycle process needs to go through four components: compressor, combustion chamber, gas turbine and waste heat boiler. In the embodiment, different modeling methods are used to model the four components that the gas cycle needs to go through. Among them, the compressor model and the gas turbine model are modeled by combining theoretical derivation and ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com