Pruner

A technology of pruning machine and power mechanism, which is applied in the field of pruning machines, can solve problems such as the research difficulties of external rotor motors and electric pruning machines that have not been studied in detail, and reduce the use time, so as to improve energy utilization efficiency, generate less heat, and The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

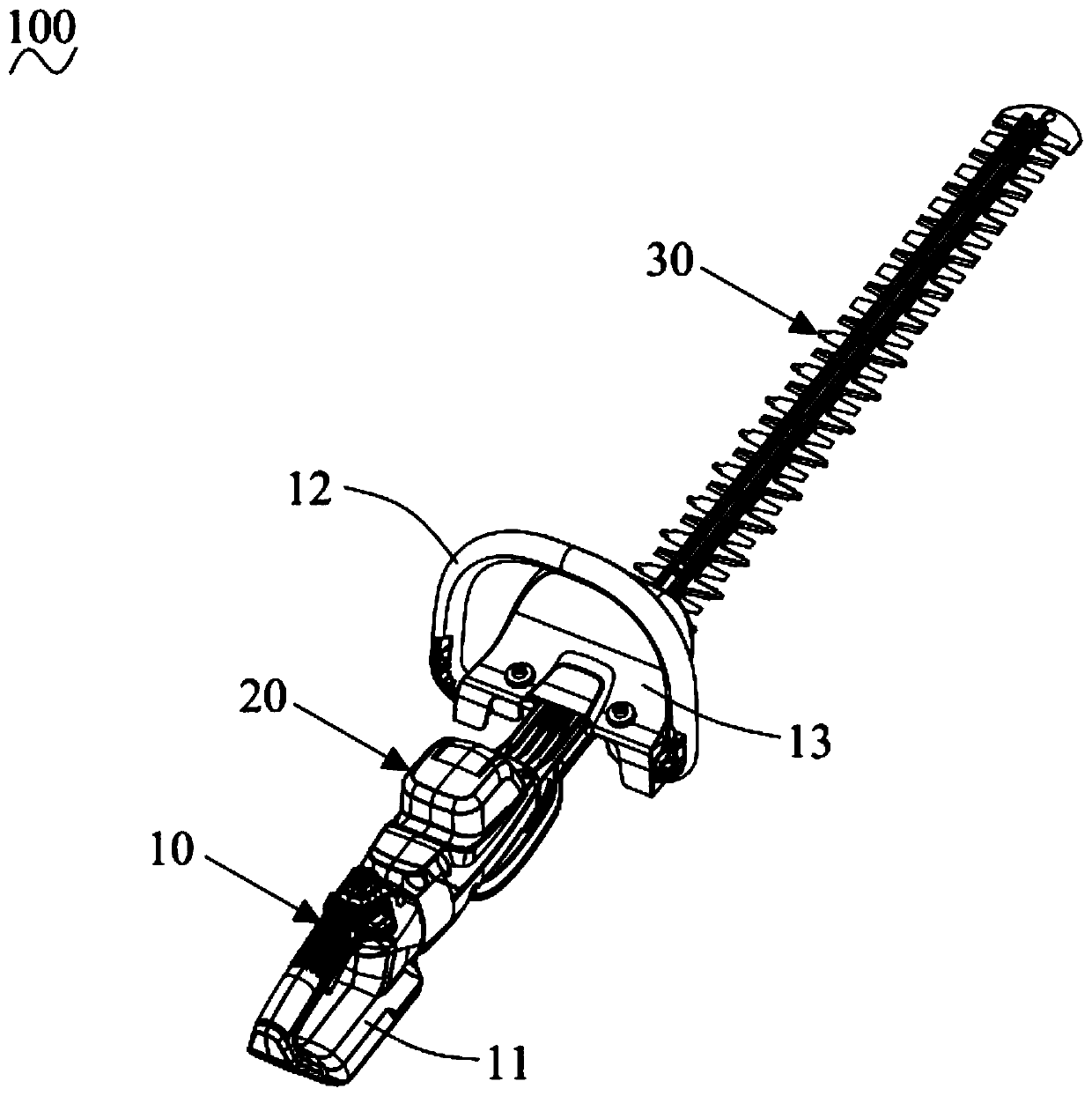

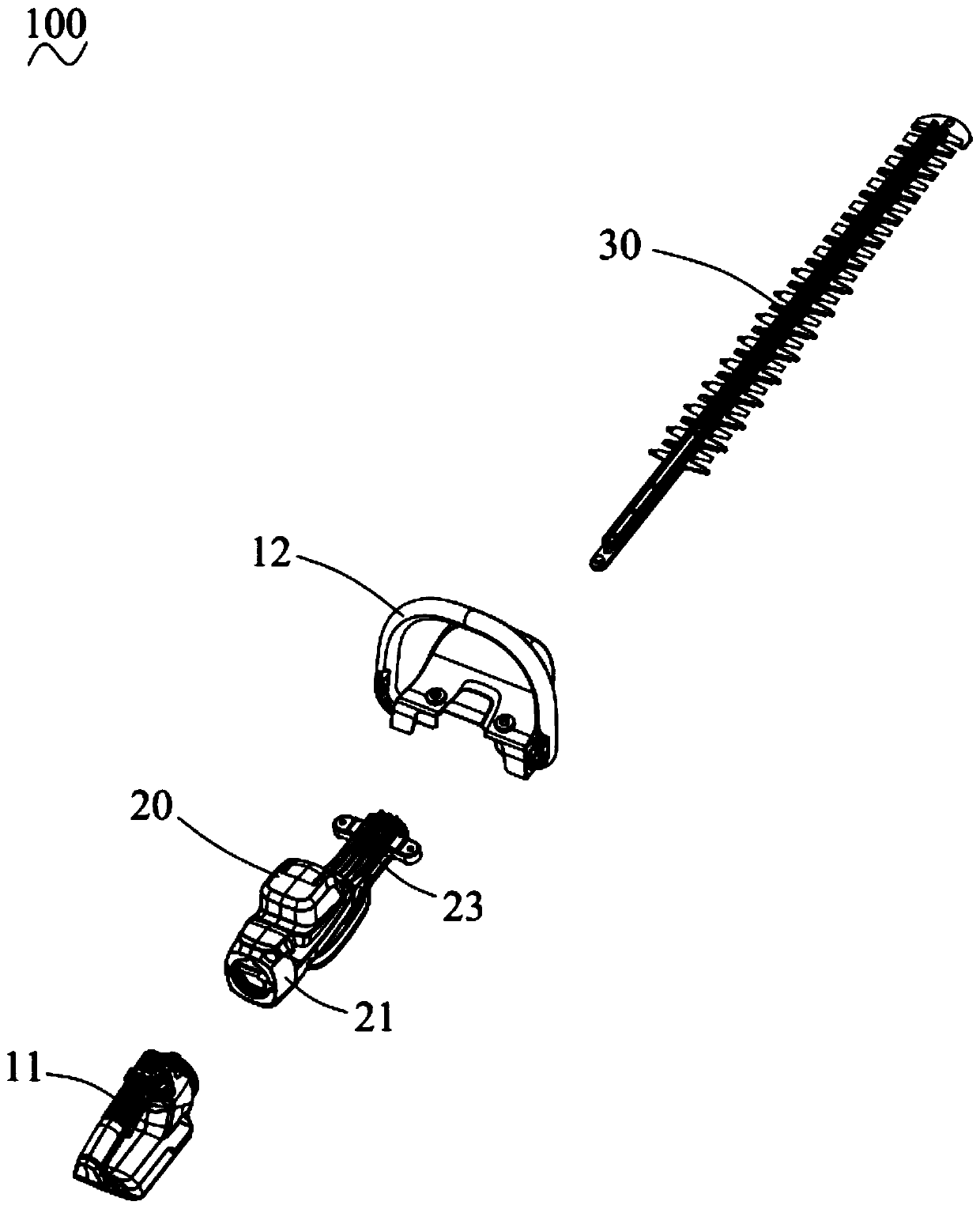

[0028] see figure 1 and figure 2 As shown, the present invention discloses a pruning machine 100 , including a handle assembly 10 , a power mechanism 20 installed at one end of the handle assembly 10 , and a blade assembly 30 connected to the power mechanism 20 .

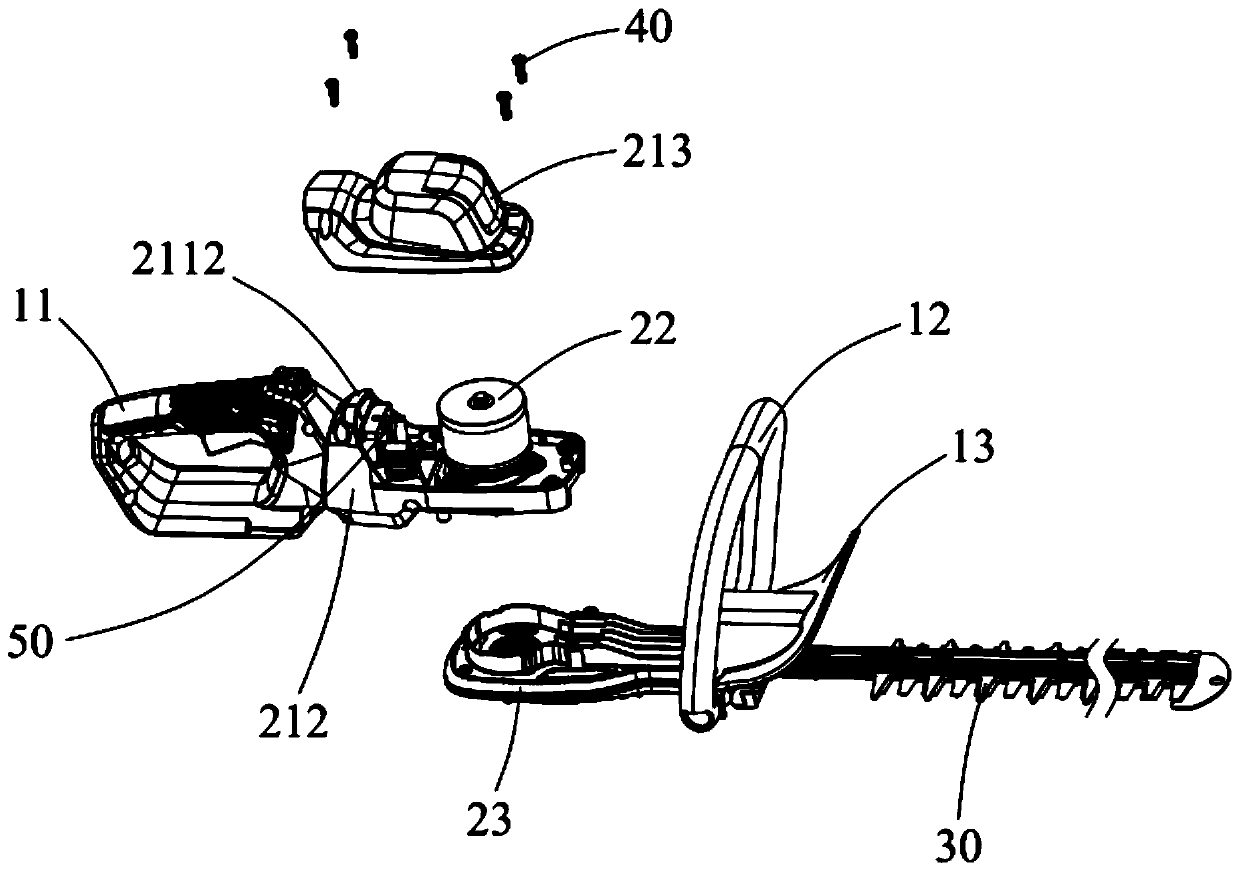

[0029] see image 3 and Figure 4 As shown, the handle assembly 10 includes a main handle 11, a secondary handle 12 and a protective plate 13. The main handle 11 is a grippable handle structure with a cavity, and the main knife switch and the speed control switch are all arranged on the on the main handle 11 for user operation. The main handle 11 and the auxiliary handle 12 are respectively arranged at two ends of the power mechanism 20, and the auxiliary handle 12 is arranged clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com