Mold core with ultrasonic vibration device

A vibrating device and ultrasonic technology, applied in cores, casting molding equipment, casting molds, etc., can solve problems such as poor exhaust, reduced production capacity and pass rate, pinhole residue, etc., to improve exhaust speed and exhaust The effect of speed, speed up filling and forming, and refinement of crystal grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners in this application will be further described below in conjunction with the accompanying drawings.

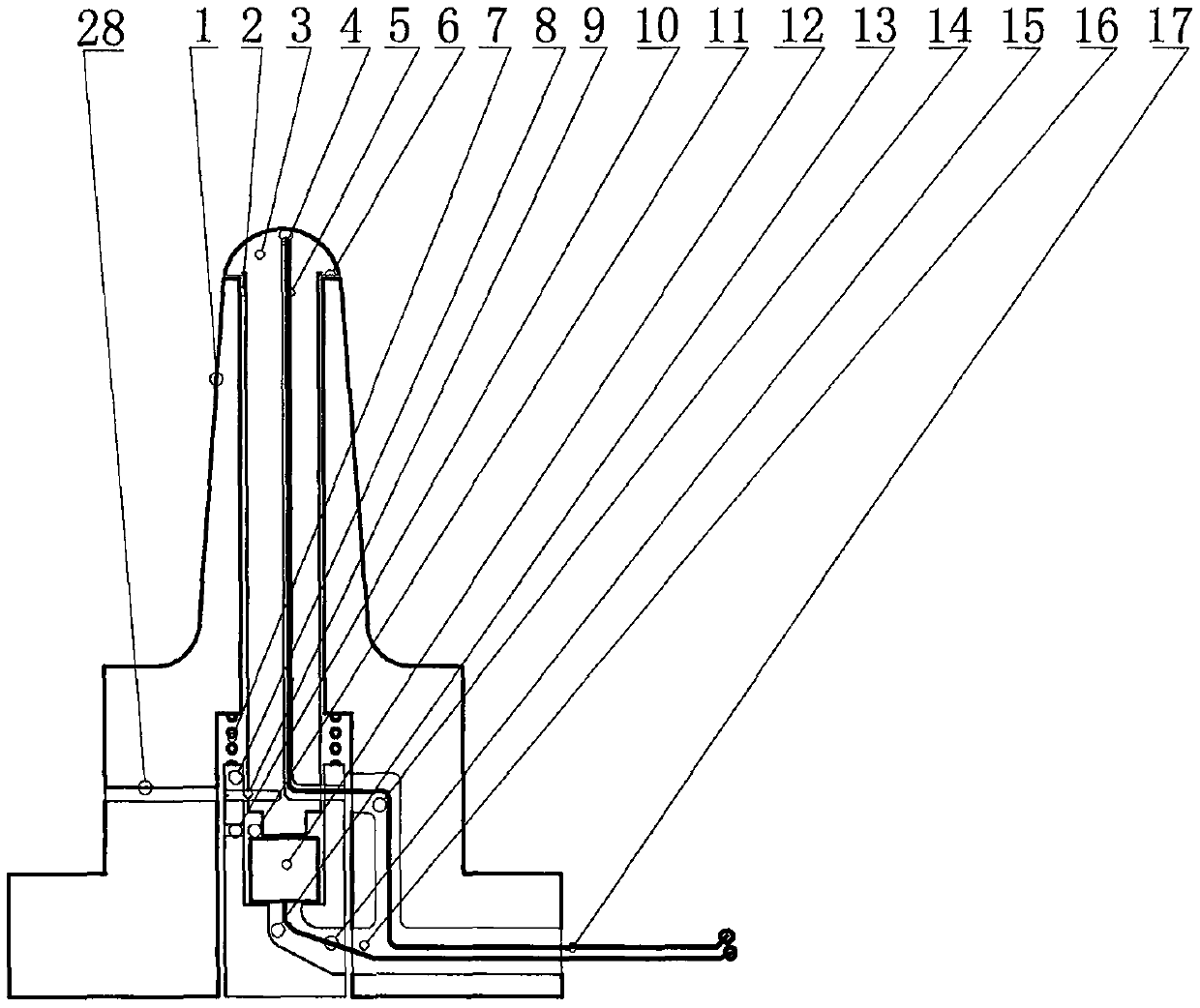

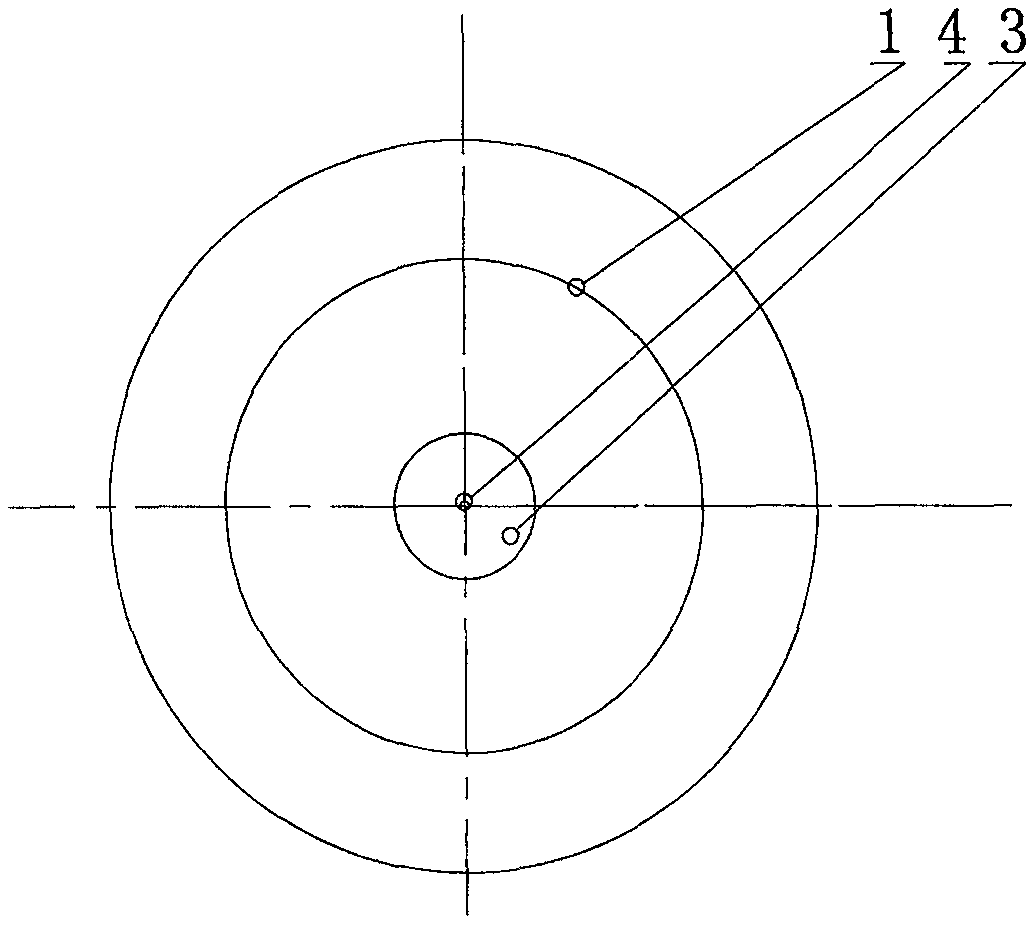

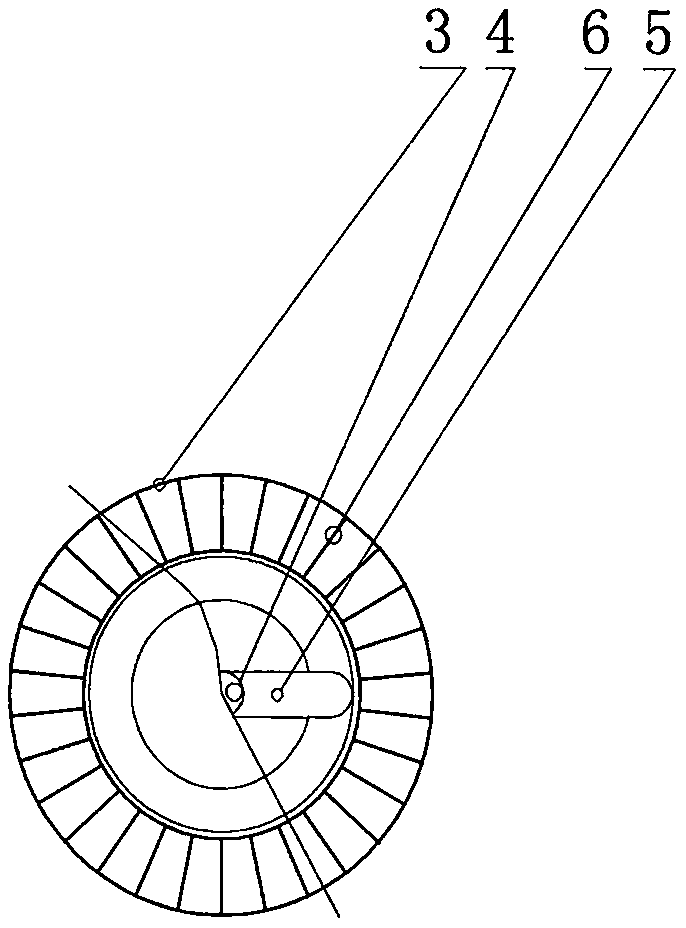

[0032] In the figure, it includes the mold core (1), the mold core hole (2), the mold core head (3), the thermocouple (4), the hole for the temperature measuring line (5), the embossed exhaust channel (6), the compression spring (7), transducer chamber (8), connecting pin (9), cooling outlet duct (10), transducer cavity (11), transducer (12), wire inlet duct (13), cooling duct (14), transducer wire (15), composite channel (16), temperature measuring line (17), compressor shell product (18), upper mold (19), mold heating pipe (20), ejector rod (21 ), lower mold composite channel (22), lower mold (23), compressor casing product runner (24), sprue cup (25), gate (26), composite channel interface (27), connecting pin installation hole (28), the top plate (29) etc. that push rod and back-moving spring are housed.

[0033] figure 1 Shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com