Three-wave circular tube anti-blocking block submerged-arc welding automatic welding device and method

A technology of automatic welding and anti-blocking block, which is applied in the direction of welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of large occupied workshop area, low space utilization rate, and low work efficiency, and achieves a small footprint and overall The effect of short length and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

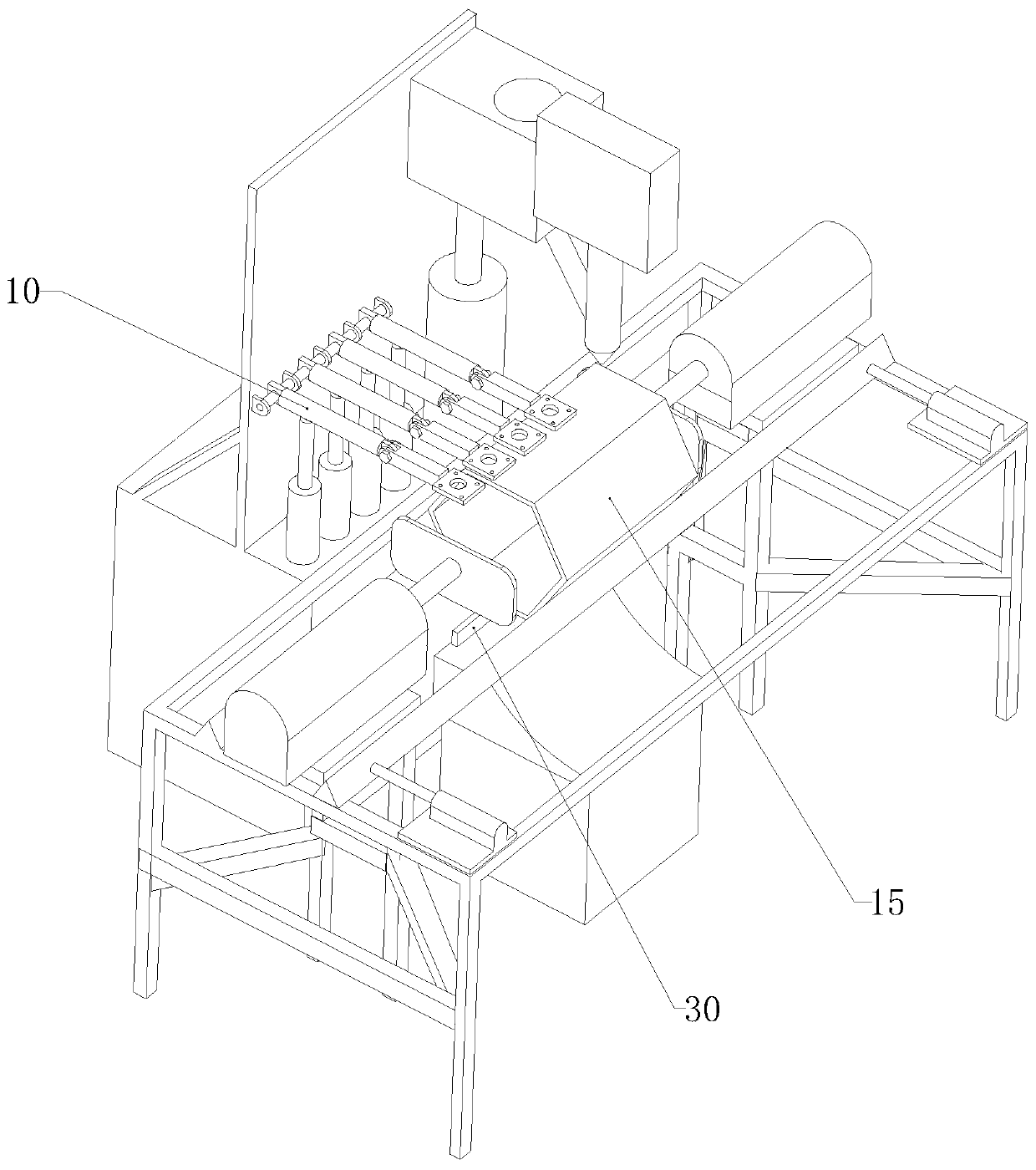

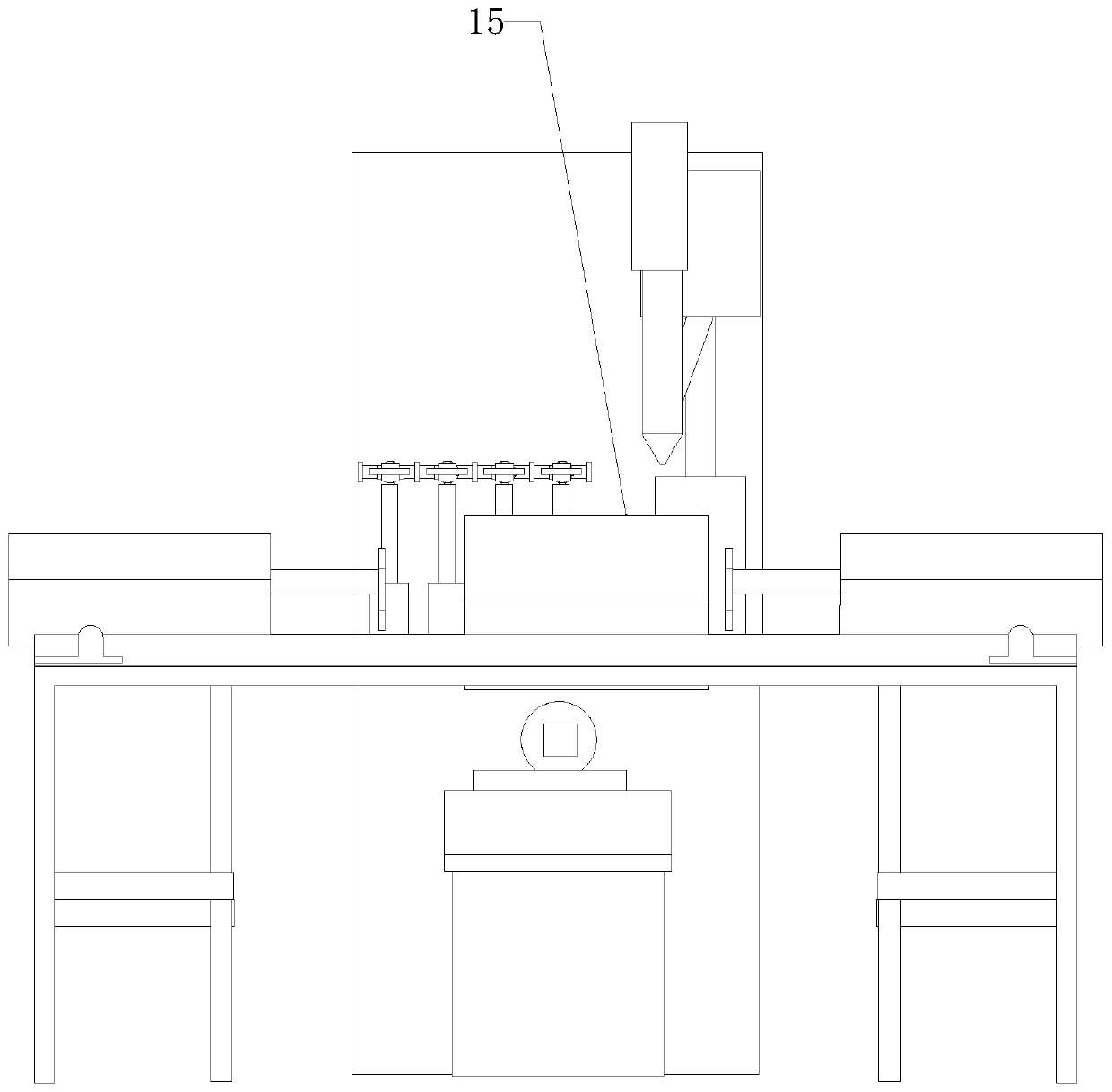

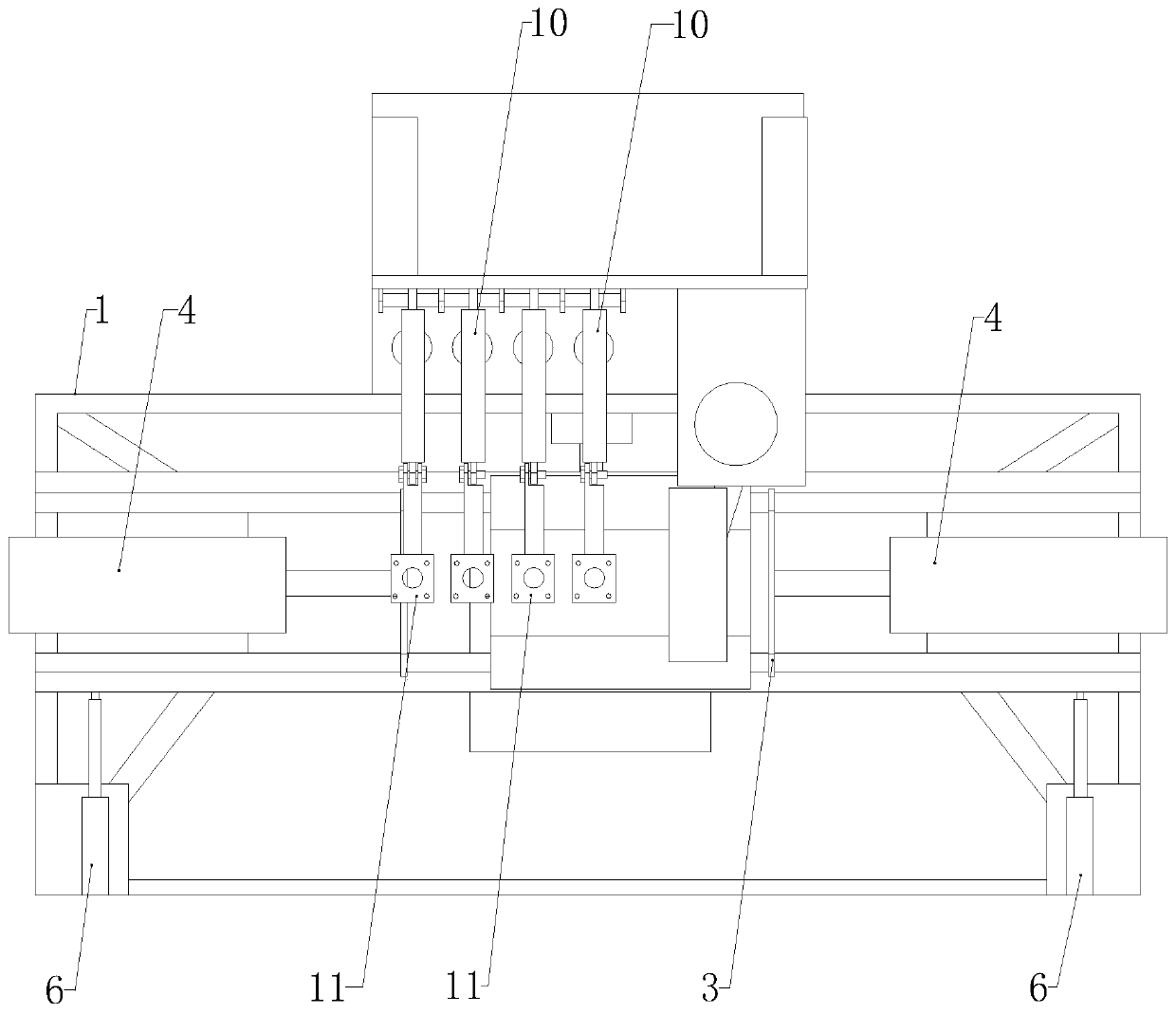

[0044] see Figure 1 to Figure 11 , a preferred embodiment of the present invention is a three-wave circular tube anti-block block submerged arc welding automatic welding device, including anti-block block support bracket and anti-block block welding device, anti-block block support bracket includes frame body 1, is located on the frame The anti-block drive assembly and the anti-block support device on the body, the anti-block drive assembly includes the anti-block push device 2 respectively located at the left and right ends of the frame body, and the anti-block push device includes a push plate 3 and a drive push plate edge The push plate driving device 4 that moves lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com