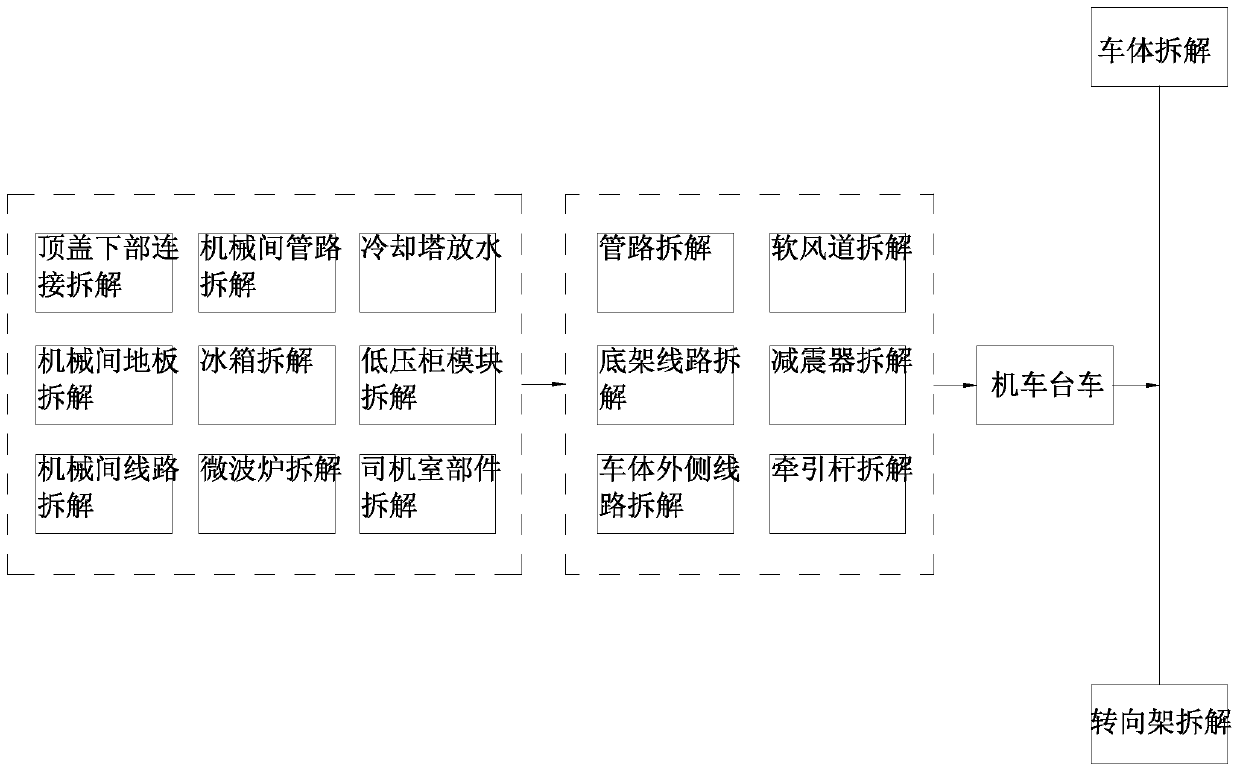

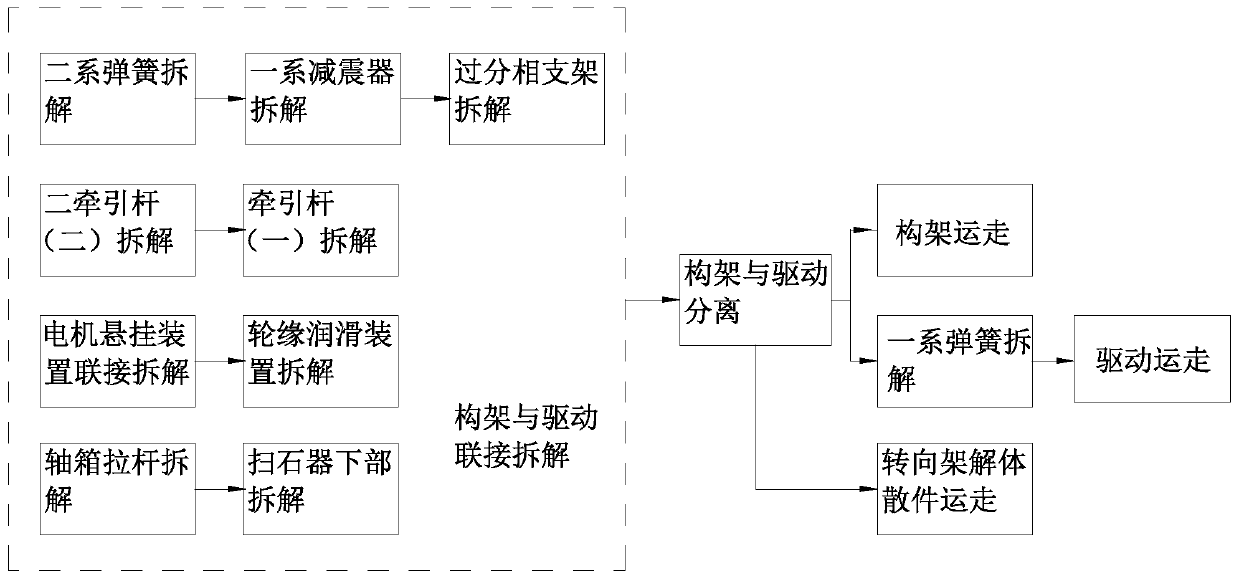

Locomotive primary disassembling process line

A technology for process lines and locomotives, applied in the direction of manufacturing tools, hand-held tools, etc., can solve problems such as the influence of production organization, poor hygiene, and difficult workshop management, and achieve the effect of improving the working environment, eliminating the bottleneck process, and reasonably and effectively controlling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

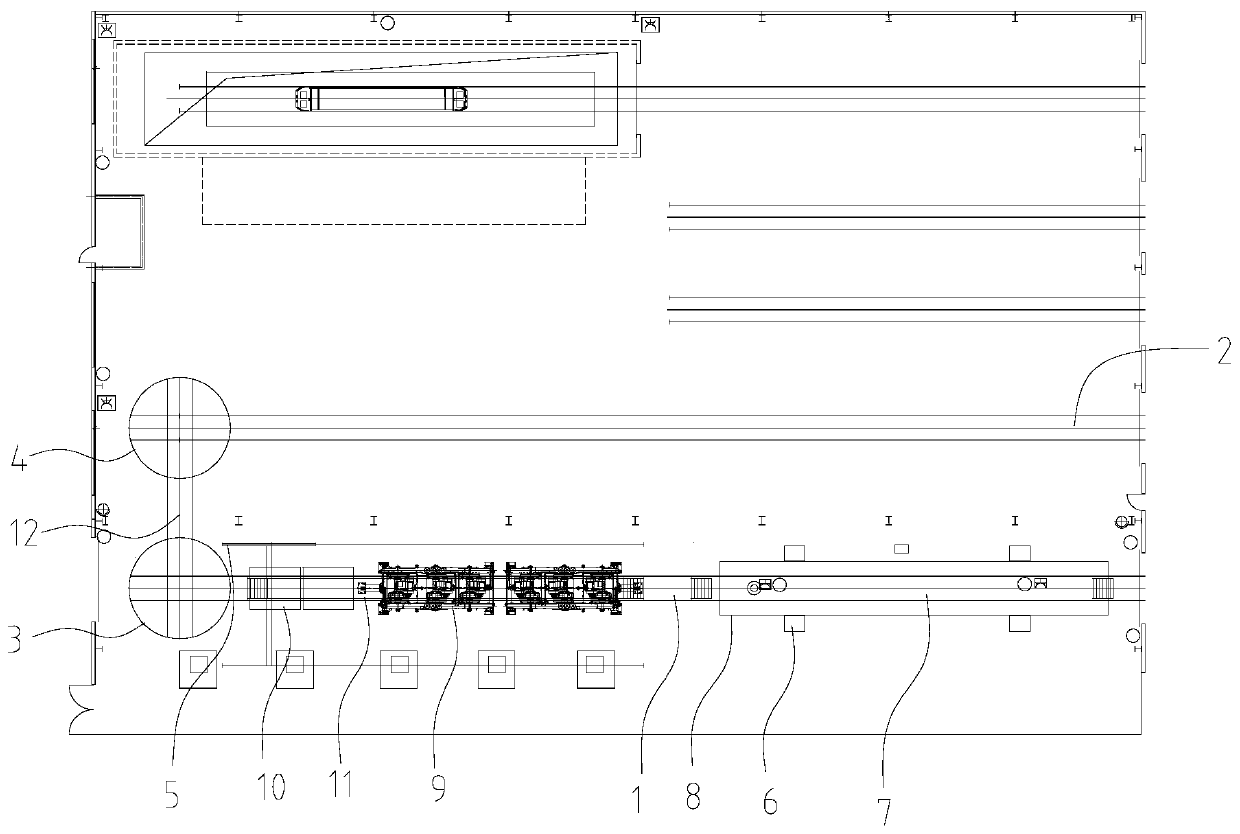

[0030] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0031] Such as image 3 As shown, a primary dismantling process line for a locomotive is used in the first-level dismantling area where the car body 8 and the bogie 9 are disassembled and separated, and the first trench 7 located in the first-level dismantling area is used for dismantling the bogie. 9’s secondary dismantling area, the second trench 11 located in the secondary dismantling area, the first track 1 running through the first trench 7 and the second trench 11, the crown block 5 arranged above the first track 1, and The second track 2 that the first track 1 is arranged in parallel and the transfer device used to connect the first track 1 and the second track 2; the transfer device includes a first turntable 3 arranged at the end of the first track 1, and The second turntable 4 at the end of the second track 2, the third track 12 between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com