A kind of waste zipper removal equipment

A zipper and equipment technology, applied in the field of waste zipper removal equipment, can solve the problems of cumbersome removal process, resource waste of plastic chain teeth, easy damage of plastic chain teeth and cloth tape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

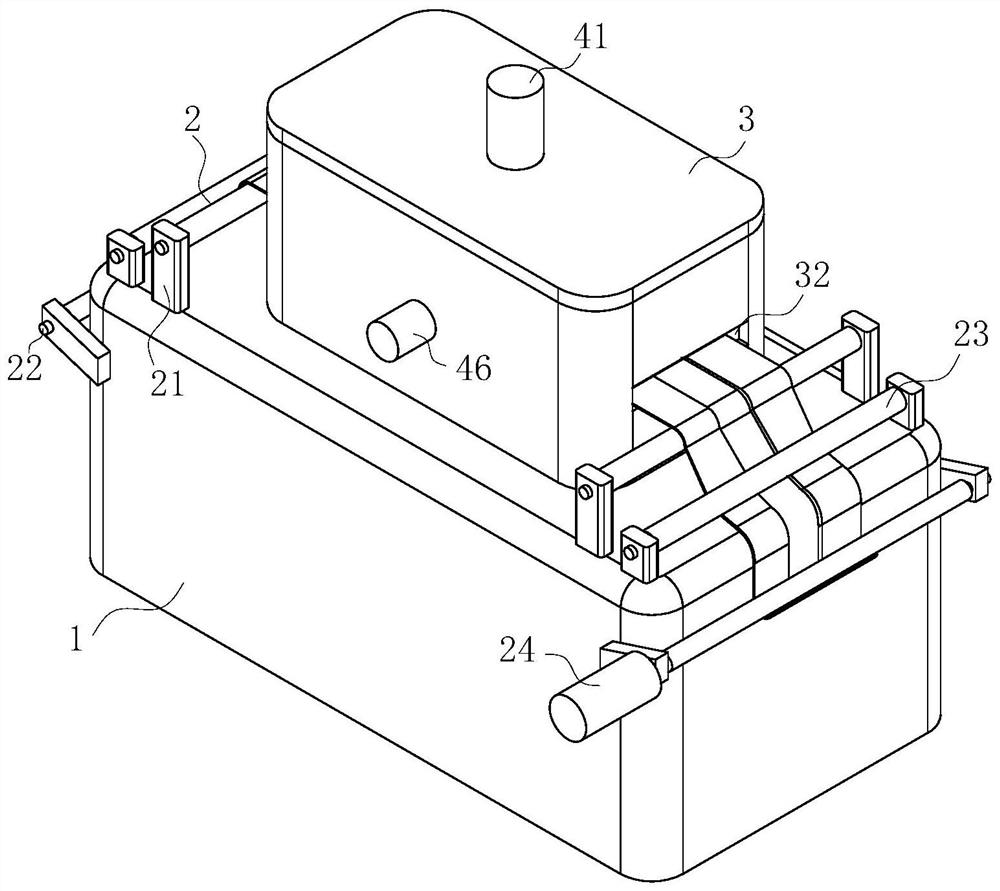

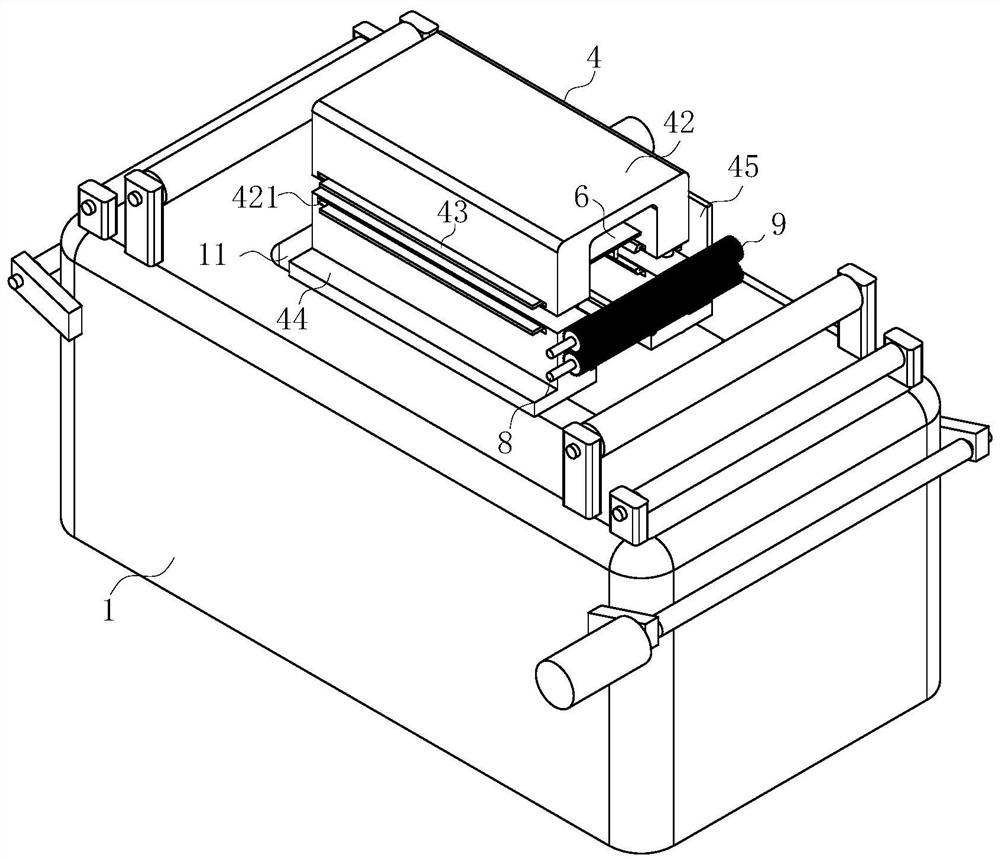

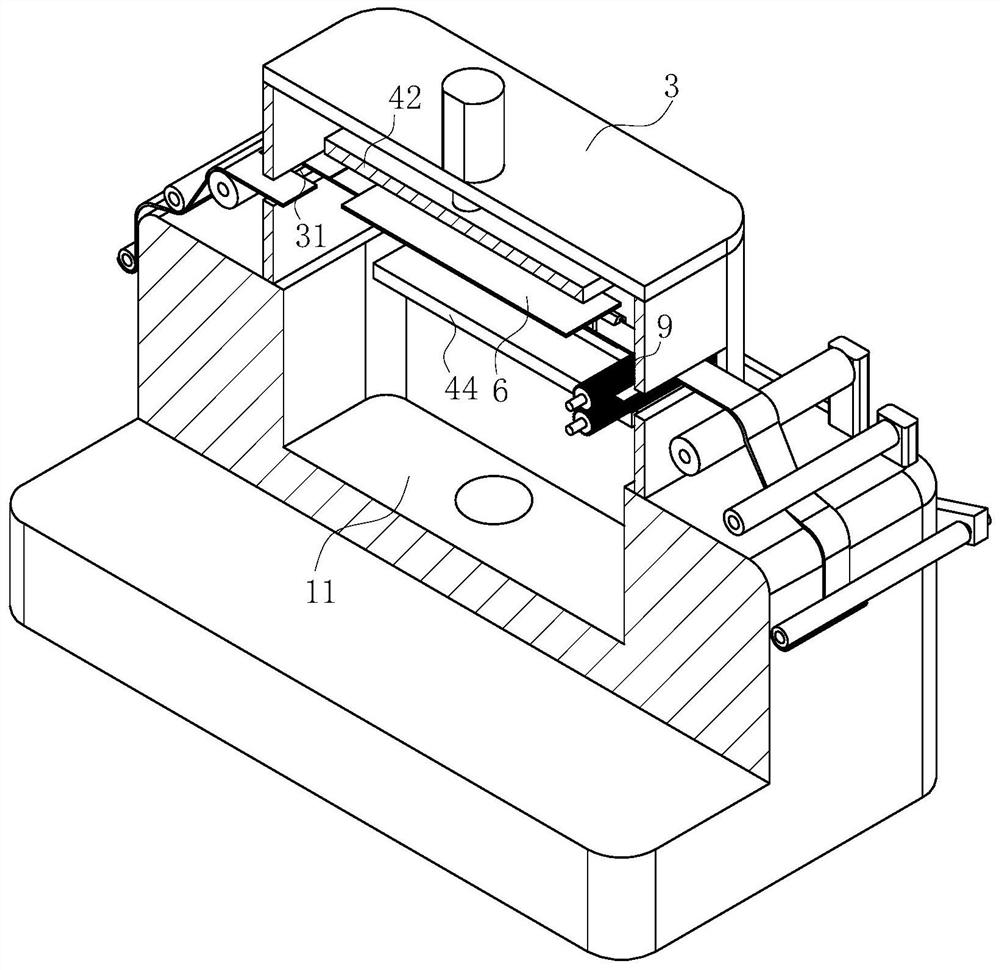

[0029] The chain element removal mechanism 4 includes a pressing cylinder 41, an upper pressing cover 42, a picking blade 43, a lower support platform 44, a guide side plate 45 and a removing hydraulic cylinder 46; the two ends of the installation cover 3 are provided with inlets Guide groove 31 and outlet guide groove 32; described compression cylinder 41 is installed on the installation cover 3, and the telescoping end of compression cylinder 41 passes installation cover 3 and is connected with upper compression cover 42, and upper compression cover 42 is set It is a U-shaped structure; the bottom end walls on both sides of the upper pressing cover 42 are provided with sliding grooves 421, and a picking blade 43 is slidably inserted in the sliding grooves 421; The upper end and the lower supporting platform 44 are also slidably equipped with picking blades 43; The part is slidingly connected; the rejecting hydraulic cylinder 46 is symmetrically installed on the installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com