Diesel oil recovery processing device for diesel generator and method thereof

A diesel generator, recycling technology, applied in separation methods, chemical instruments and methods, filter circuits, etc., can solve the problems of increasing the contact area between filter sand and filter cloth, failing to exert adsorption and removing impurities, and unable to replace them in time. To achieve the effect of quick disassembly and assembly, preventing waste of filter sand, and convenient and rapid replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

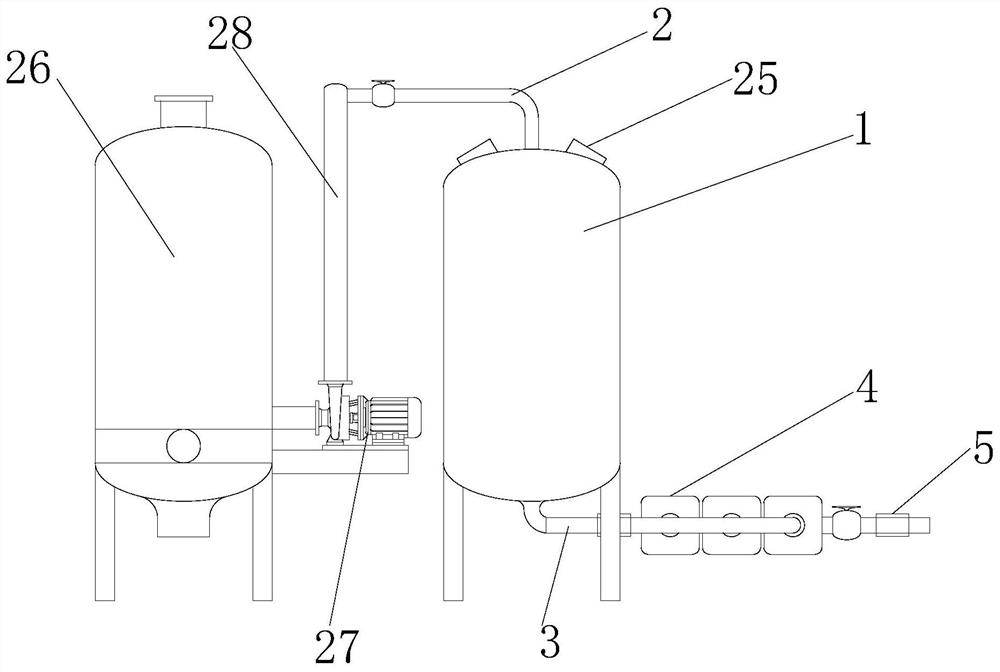

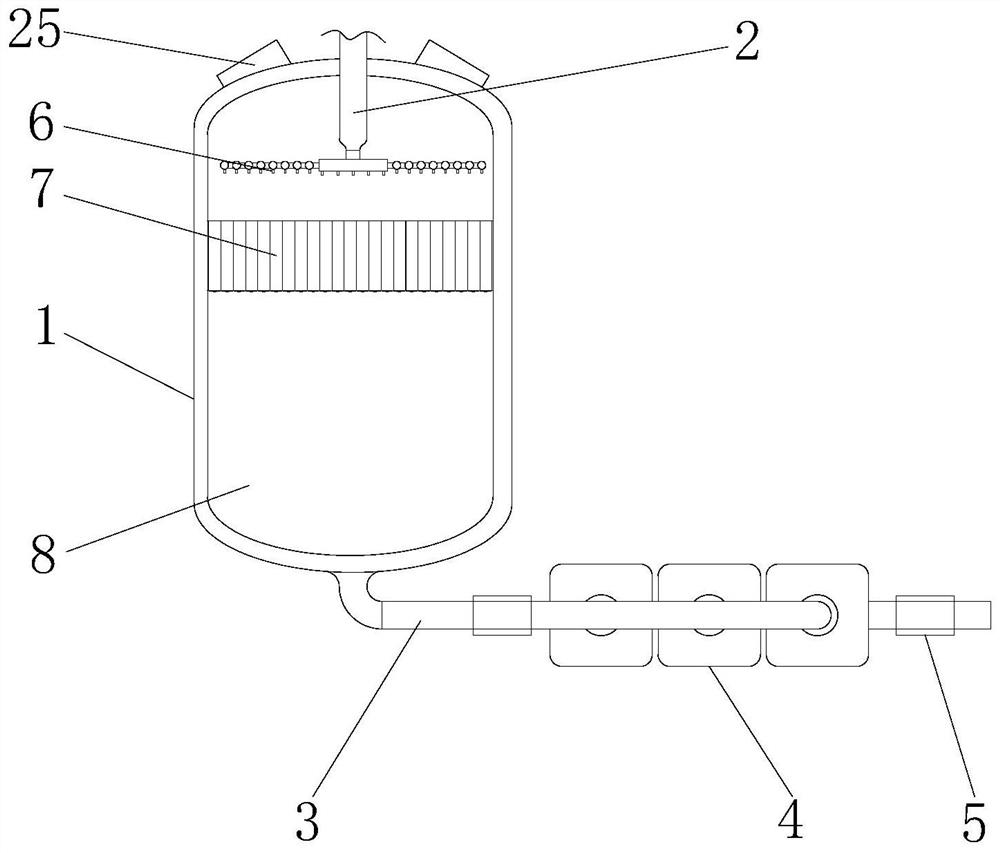

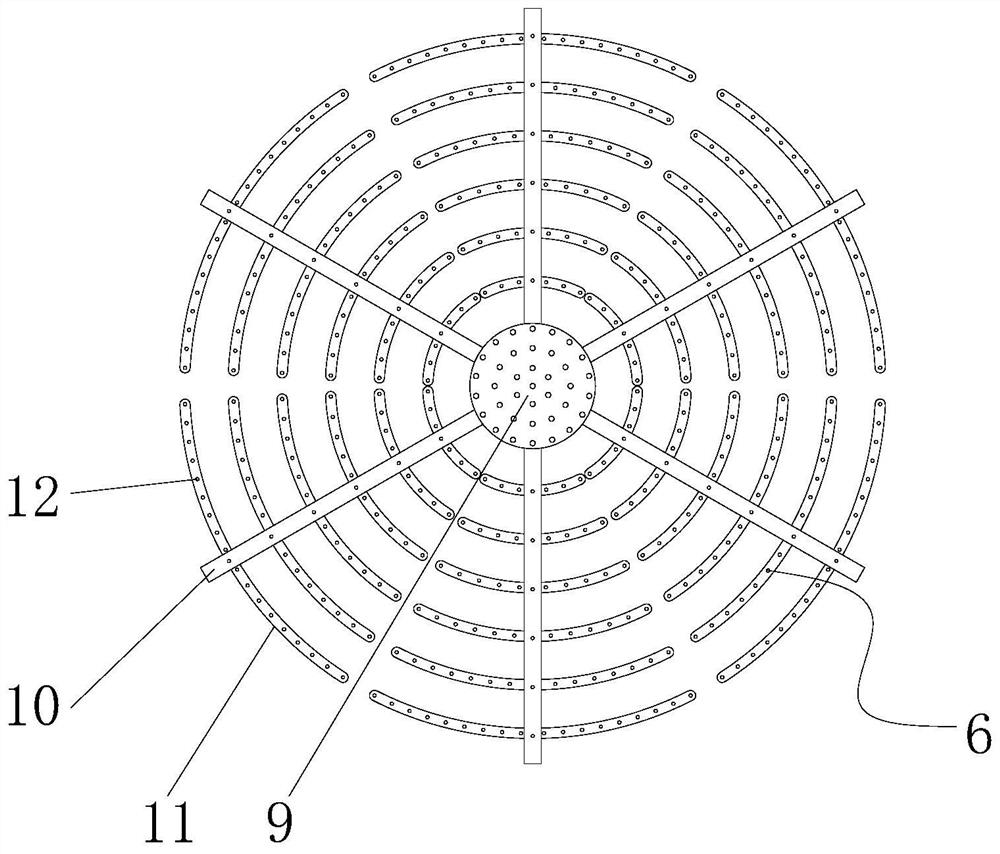

[0035] see Figure 1-6 Shown: a diesel oil recovery and treatment device for diesel generators, including a recovery tank 1, the top of the recovery tank 1 is pierced with an oil inlet pipe 2, the lower end of the oil inlet pipe 2 is installed with a fuel injector 6, and the inner upper part of the recovery tank 1 is installed There is a hole plate 7, the hole plate 7 is located directly below the fuel injector 6, the inner middle and lower part of the recovery tank 1 are filled with filter sand 8, and each straight hole of the hole plate 7 is also filled with filter sand 8, the recovery tank 1 The lower end of the oil discharge pipe 3 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com