Front cabin arrangement structure of pure electric automobile

A pure electric vehicle and layout structure technology, which is applied in the field of front cabin layout structure of pure electric vehicles, can solve the problem that the natural cooling battery pack cannot meet the requirements of charging and discharging safety and efficiency, the parts are connected with complex high-voltage wiring harnesses, and the space utilization rate is not good. Advanced problems, to avoid excessive displacement of the electric drive, facilitate assembly and maintenance, and improve the efficiency of final assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

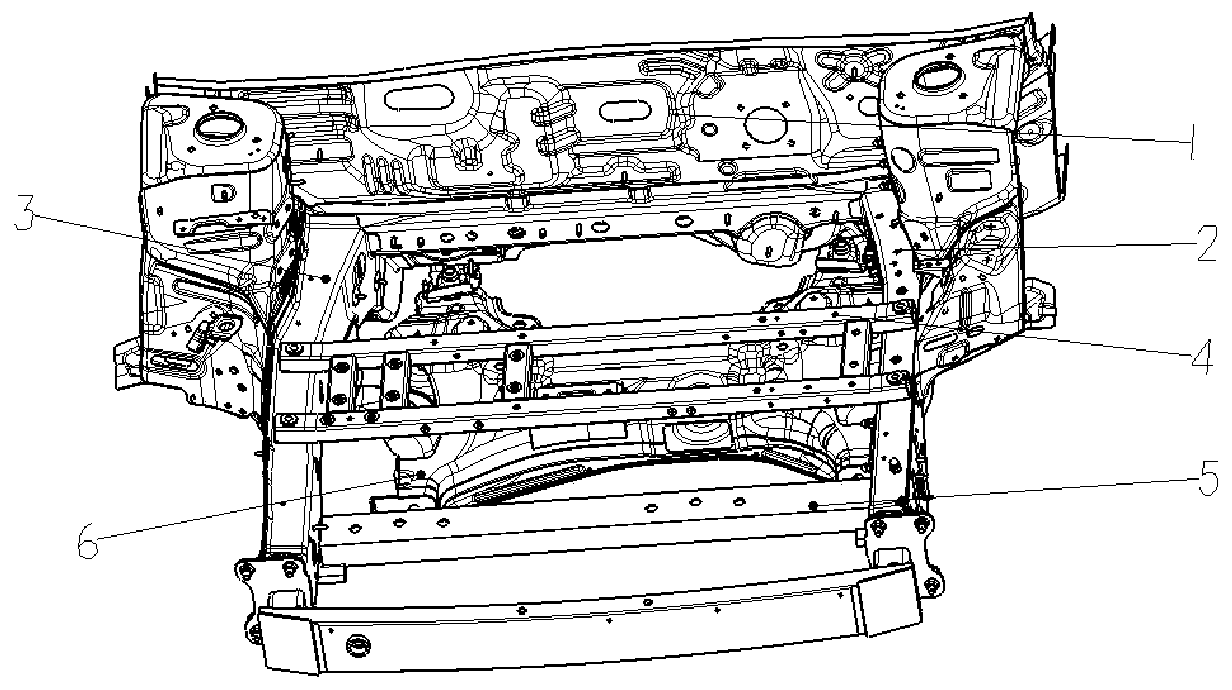

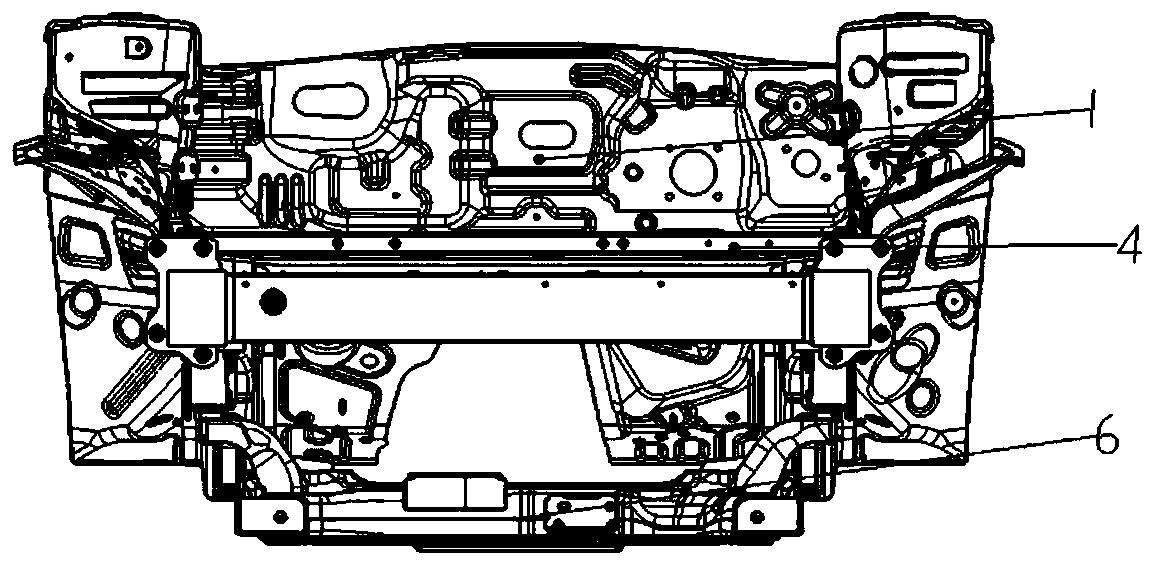

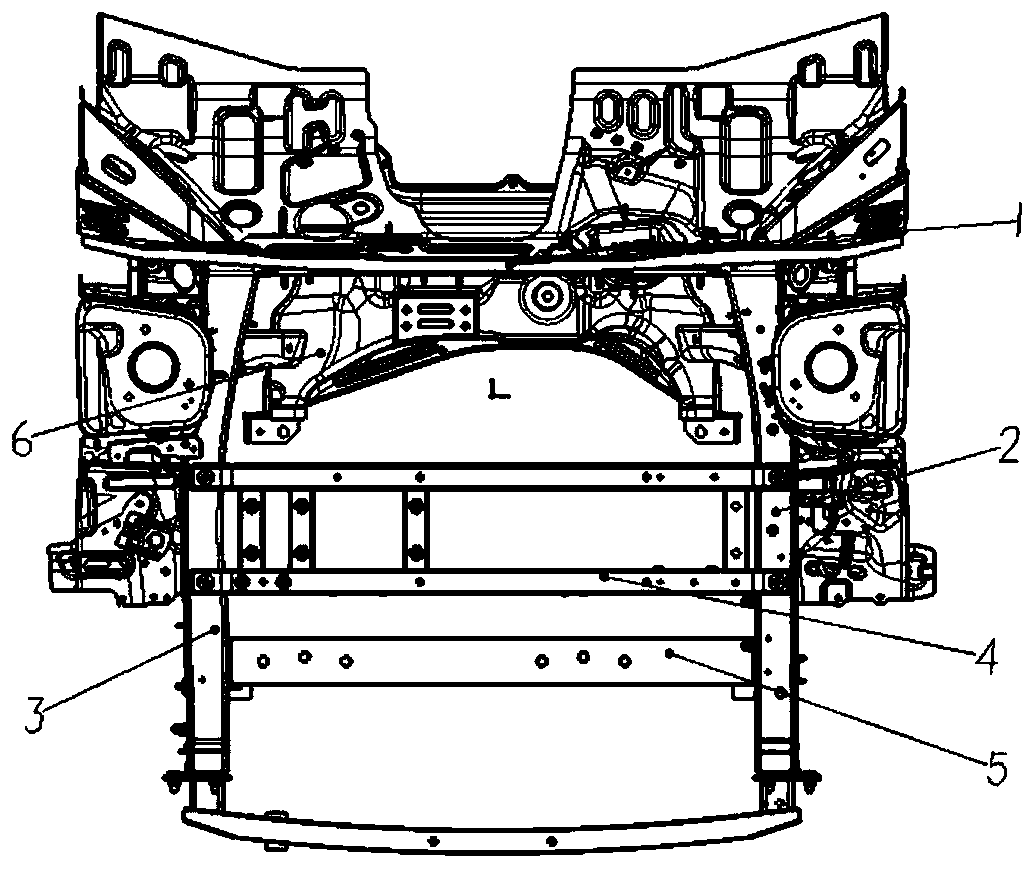

[0032] Such as Figure 1 to Figure 10 As shown, the layout structure of the front cabin of the pure electric vehicle includes the front cabin body 1, left longitudinal beam 2, right longitudinal beam 3, cross beam, electric drive assembly, vacuum system, power supply system, low-voltage electrical components, and thermal management system And subframe 6; crossbeam comprises upper crossbeam assembly 4 and lower crossbeam 5, and the two ends of upper crossbeam assembly are connected with the upper surface of left and right crossbeam respectively, and the two ends of lower crossbeam are respectively connected with the lower surface of left and right crossbeam The front part of the electric drive assembly is connected to the lower beam, the rear part of the electric drive assembly is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com