Low-temperature sealing machine for biodegradable film

A biodegradable film and sealing machine technology, applied in packaging sealing/fastening, external support, transportation packaging, etc., can solve the problems of biodegradable film failure and no heat dissipation function, and achieve the effect of avoiding failure and facilitating sealing work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

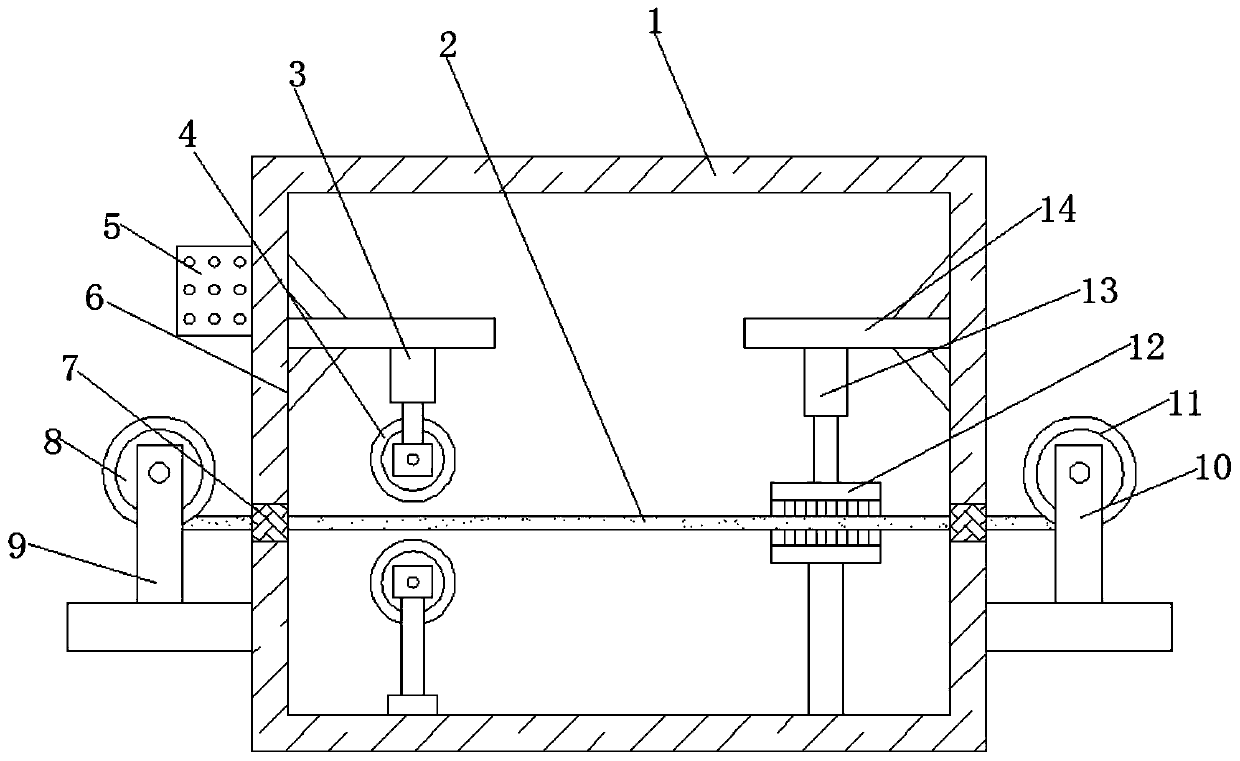

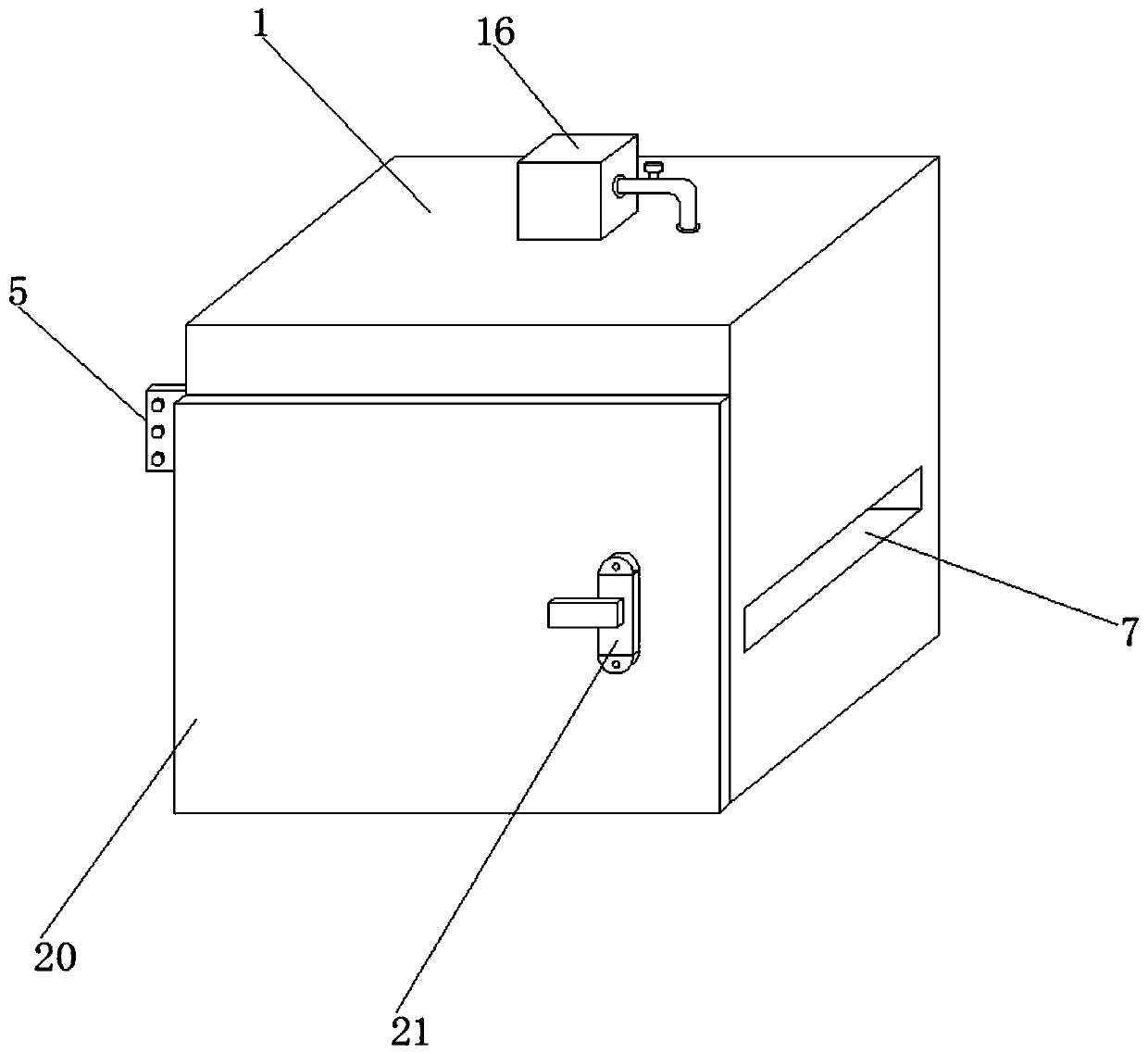

[0026] refer to Figure 1-2 , a low-temperature sealing machine for biodegradable films, comprising a box body 1, a first mounting plate is connected to one side outer wall of the box body 1 by bolts, and a first fixing rod 9 is connected to the top outer wall of the first mounting plate by bolts, One side outer wall of the first fixed rod 9 is rotatably connected with an unwinding roller 8, and the peripheral outer wall of the unwinding roller 8 is wound with a biodegradable film 2, and one side outer wall of the casing 1 is connected with a second connecting plate by bolts, and the second connecting plate The bottom outer wall of the second connecting plate is connected with the first electric push rod 3 by bolts, the one side outer wall of the second connecting plate is welded with a reinforcing rod 6, and the outer wall of one end of the first electric push rod 3 is connected with a fixed block by bolts, and the fixed block A pressure roller 4 is rotatably connected to one...

Embodiment 2

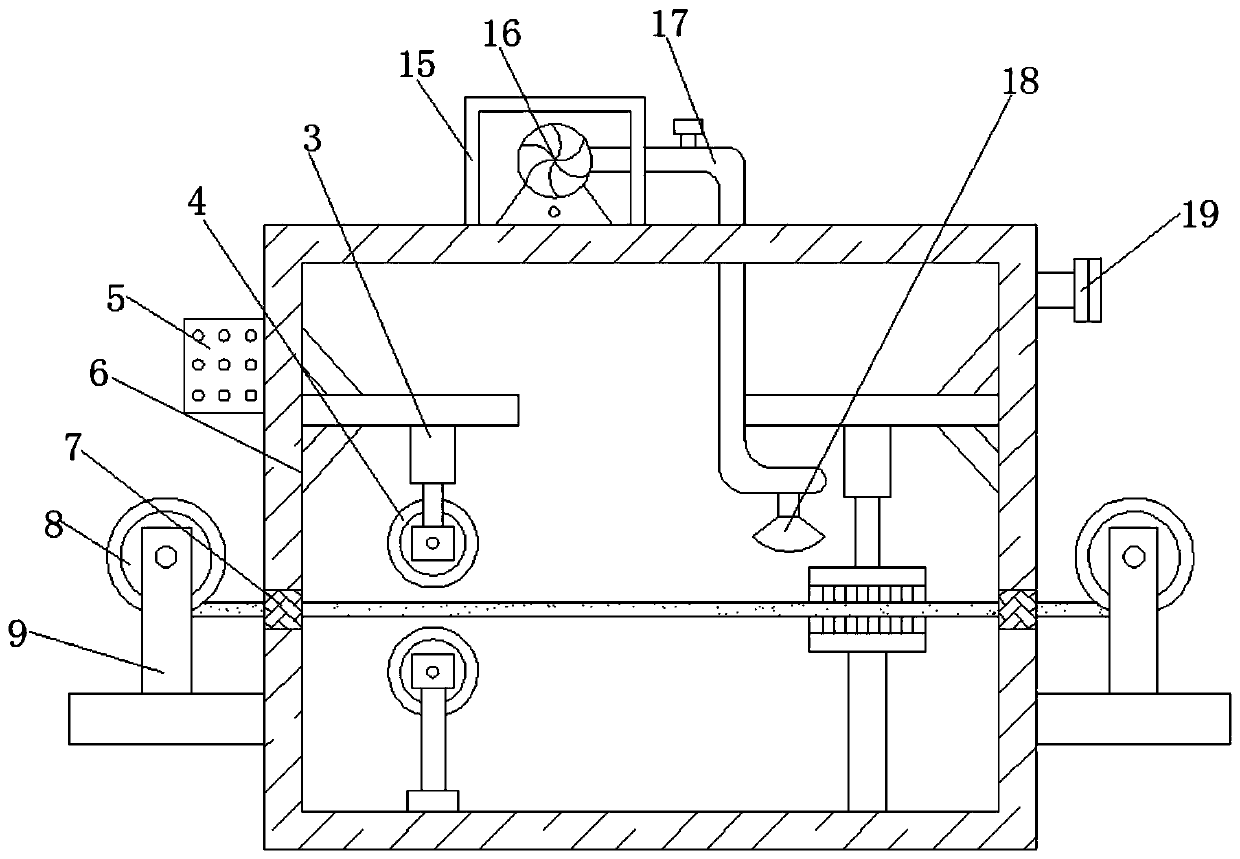

[0030] refer to image 3 , a low-temperature sealing machine for biodegradable films. Compared with Embodiment 1, the top outer wall of the box body 1 is connected with a protective shell 15 by bolts, and the bottom inner wall of the protective shell 15 is connected with a blower 16 by bolts. The blower One side outer wall of 16 is plugged with air guide pipe 17 , the bottom outer wall of air guide pipe 17 is plugged with air outlet bucket 18 , one side outer wall of box body 1 is plugged with ventilation pipe 19 .

[0031] Working principle: When in use, the staff passes one end of the biodegradable film 2 through the two through grooves 7 respectively, and at the same time starts the first electric push rod 3 when the biodegradable film 2 is sealed, and the first electric push rod 3 Driving the pressure roller 4 to move up and down can guide the biodegradable film 2, which facilitates the subsequent sealing work. At the same time, the height of the pressure roller 4 driven b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com