Nitrogen charging device for puffed food production and processing

A technology of puffed food and nitrogen tank, which is applied in the direction of packaging food, packaging by pressurization/gasification, packaging, etc., can solve the problems that the automation of nitrogen filling cannot be realized, and achieve the goal of improving practicability, improving efficiency, and simplifying the operation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

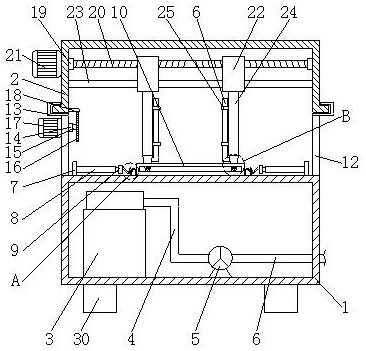

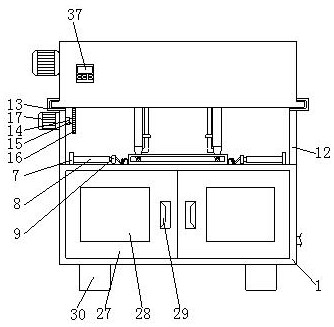

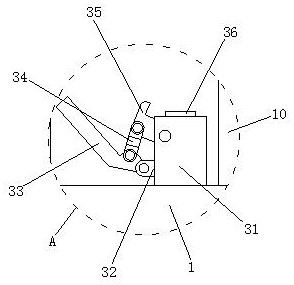

[0027] Embodiment: put one side of the food bag on the backing plate 36, by pulling the pull rod 33, the pull rod 33 drives the spring leaf 34 to move, the spring leaf 34 is compressed at the same time, and the spring leaf 34 drives the hook 35 to move, when the pull rod 33 moves to When in the vertical direction, under the elastic force of the spring leaf 34, the hook 35 compresses the food bag on the backing plate 36, and by controlling the work of the air pump 5, the nitrogen gas is drawn out from the nitrogen tank 3 and passed through the air-inducing head 26. It is said that by controlling the electric push rod 8 to work with the sealing machine 9, the electric push rod 8 drives the sealing machine 9 to move toward each other. While the sealing machine 9 is sealing the food bag, by controlling the second motor 21 to work, the second motor 21 Drive the threaded rod 20 to rotate, the threaded rod 20 drives the transmission body 22 to move towards each other, the transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com