A steel plate with excellent low-temperature toughness for explosive compounding and its production method

A technology of low temperature toughness and production method, applied in the field of metallurgy, can solve the problems of decreased plastic toughness and increased dislocation density of steel substrate grains, and achieves the effects of internal compactness, excellent mechanical properties, and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

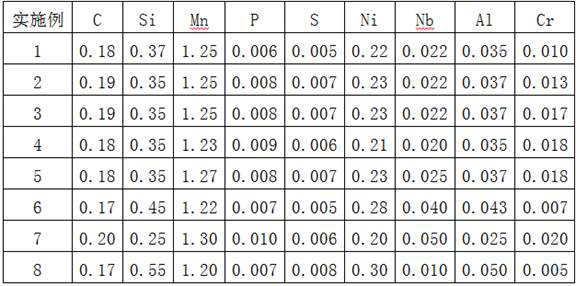

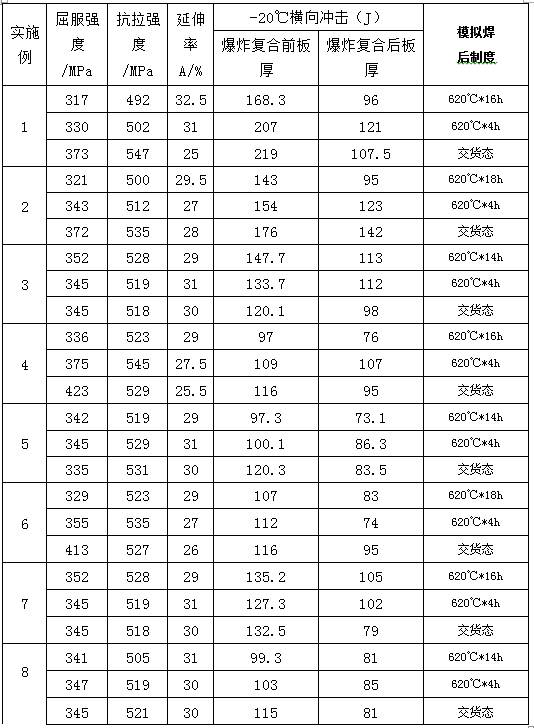

[0022] The thickness of the steel plate with excellent low-temperature toughness used for explosive compounding in this embodiment is 60 mm, and the chemical composition and mass percentage of the steel plate are shown in Table 1.

[0023] The production method of the steel plate with excellent low-temperature toughness for explosive compounding in this embodiment includes smelting, continuous casting, heating, rolling, cooling after rolling, and heat treatment processes. The specific process steps are as follows:

[0024] (1) The smelting process: including primary smelting, LF furnace refining, VD furnace vacuum treatment:

[0025] A. Primary smelting: high-quality materials are first selected for smelting in electric furnaces, and the conditions for tapping steel in primary smelting furnaces: P: 0.008%;

[0026] B. Refining in LF furnace: Put the initial molten steel into the LF furnace for refining, adjust the composition of each element, the total refining time is 65 minu...

Embodiment 2

[0035] The thickness of the steel plate with excellent low-temperature toughness used for explosive compounding in this embodiment is 90 mm, and the chemical composition and mass percentage of the steel plate are shown in Table 1.

[0036] The production method of the steel plate with excellent low-temperature toughness for explosive compounding in this embodiment includes smelting, continuous casting, heating, rolling, cooling after rolling, and heat treatment processes. The specific process steps are as follows:

[0037] (1) The smelting process: including primary smelting, LF furnace refining, VD furnace vacuum treatment:

[0038] A. Primary smelting: high-quality materials are first selected for smelting in electric furnaces, and the conditions for tapping steel in primary smelting furnaces: P: 0.007%;

[0039] B. Refining in LF furnace: put the initial molten steel into the LF furnace for refining, adjust the composition of each element, the total refining time is 62 minu...

Embodiment 3

[0048] The thickness of the steel plate with excellent low-temperature toughness used for explosive compounding in this embodiment is 120 mm. The chemical composition and mass percentage of the steel plate are shown in Table 1.

[0049] The production method of the steel plate with excellent low-temperature toughness for explosive compounding in this embodiment includes smelting, die casting, heating, rolling, post-rolling cooling, and heat treatment processes. The specific process steps are as follows:

[0050] (1) The smelting process: including primary smelting, LF furnace refining, VD furnace vacuum treatment:

[0051] A. Primary smelting: high-quality materials are first selected for smelting in electric furnaces, and the conditions for tapping steel in primary smelting furnaces: P: 0.006%;

[0052] B. Refining in LF furnace: Put the initial molten steel into the LF furnace for refining, adjust the composition of each element, the total refining time is 61 minutes, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com