Yarn winding mechanism of roving frame and roving frame production line having the same

A technology of roving frame and frame, which is applied in the direction of spinning machine, continuous winding spinning machine, textile and paper making, etc. It can solve the problems of high labor cost and high degree of labor participation, so as to save labor cost and reduce The effect of work intensity and high promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

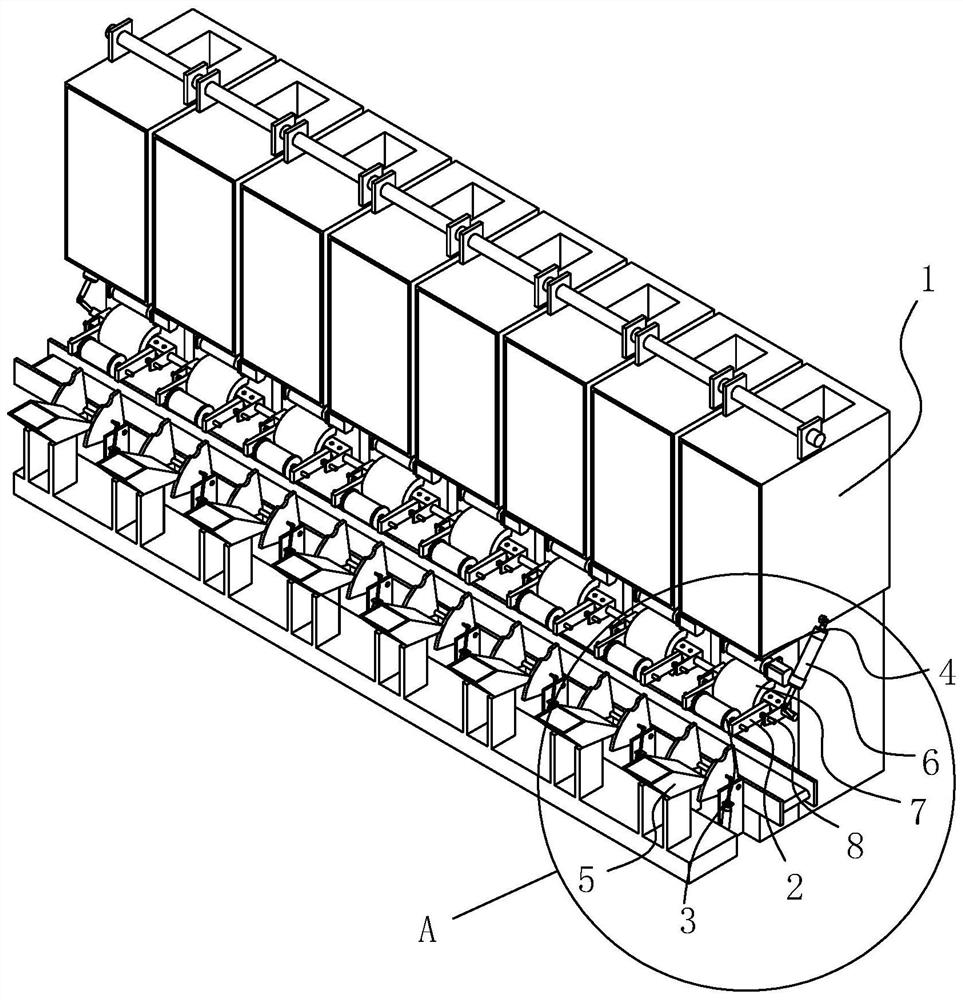

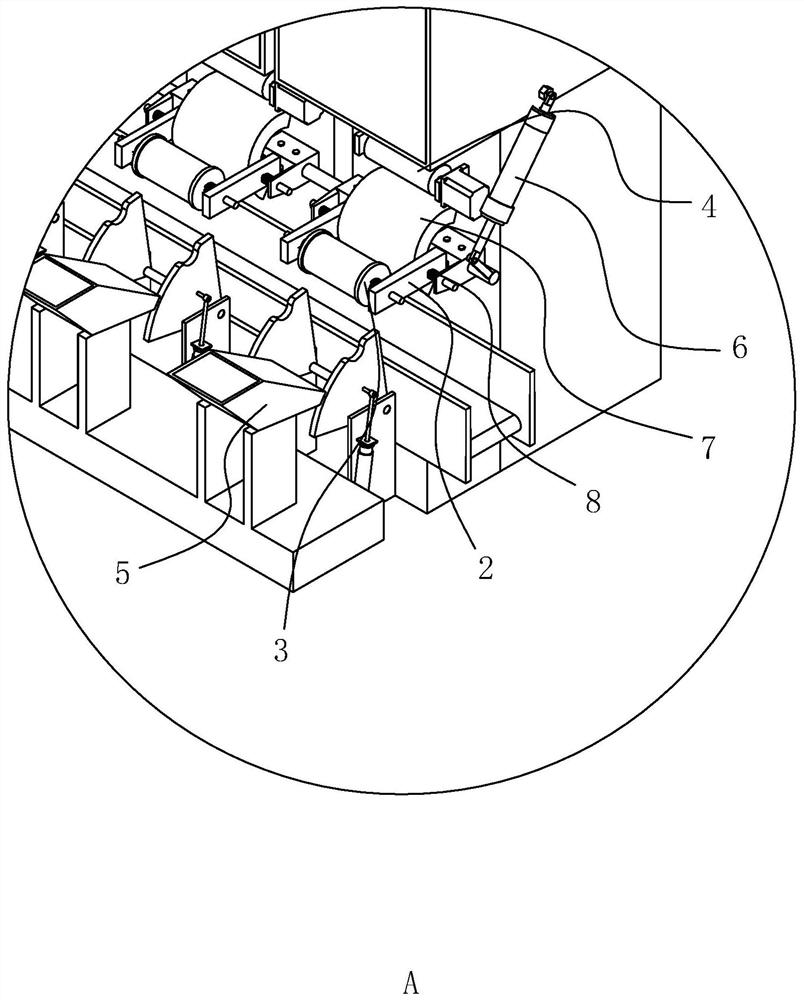

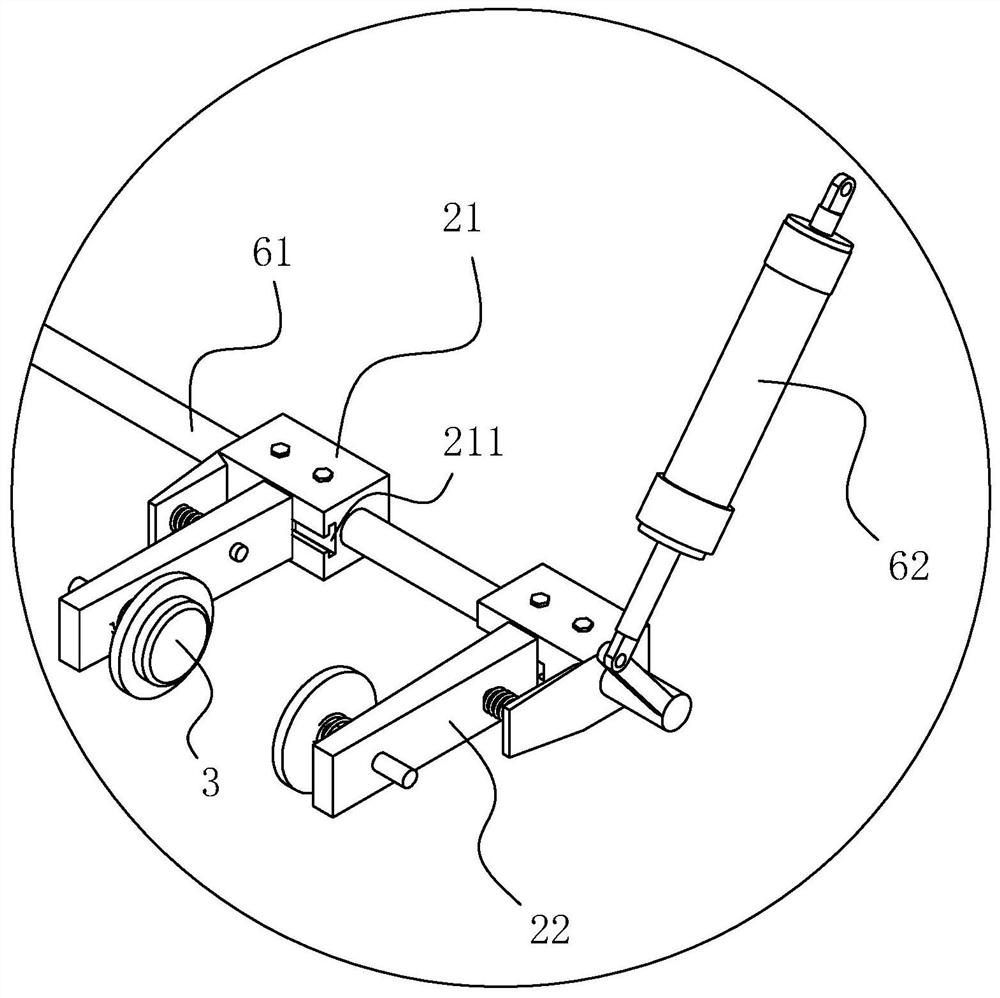

[0050] A slubbing frame winding mechanism, combined with figure 1 and figure 2 As shown, it includes two clamping parts 3 arranged on the frame 1 for respectively clamping the left and right ends of the yarn bobbin, rotatably connected to the frame 1 and rotatably connected with the clamping part 3 for controlling the clamping part 3 Clamping arm assembly 2 for clamping or loosening the bobbin, set on the frame 1 and capable of engaging with the bobbin clamped by the clamping arm assembly 2 for driving the bobbin to rotate itself, the friction roller assembly 4, set on On the frame 1, the can changer assembly 5 for providing new yarn reels for the jig arm assembly 2 is arranged on the frame 1 for driving the jig arm assembly 2 to rotate so that the jig arm assembly 2 can access the cannula changer assembly 5 The rotating shaft mechanism 6 of the ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com