Energy-absorbing highway guardrail and damping elastomer

A technology of road guardrails and elastic bodies, which is applied in the direction of roads, roads, road safety devices, etc., can solve problems such as bending or loosening of columns, high manpower and material costs, and vehicle damage, so as to improve safety performance, enhance protection performance, Good energy absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

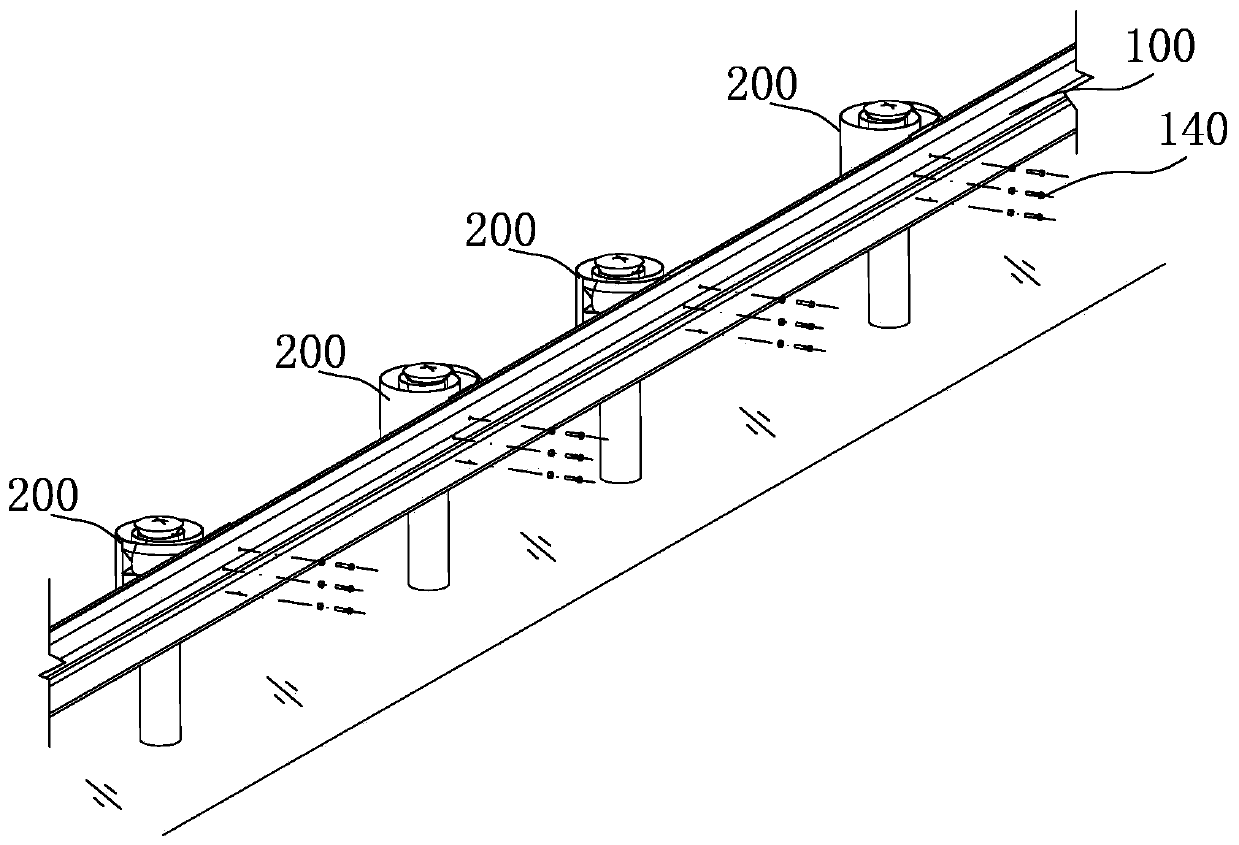

[0071] Embodiment one, such as Figure 2 to Figure 5 As shown, in this embodiment, without special description, each crash barrier unit includes a double wave corrugated plate, at least two uprights, at least two damping elastic bodies, and several pull bolt assemblies and bolt assemblies, wherein the pull bolt assemblies or Bolt assemblies or screws are collectively referred to as fasteners. In the actual implementation process, it is clear to choose the appropriate fasteners according to the different connection occasions.

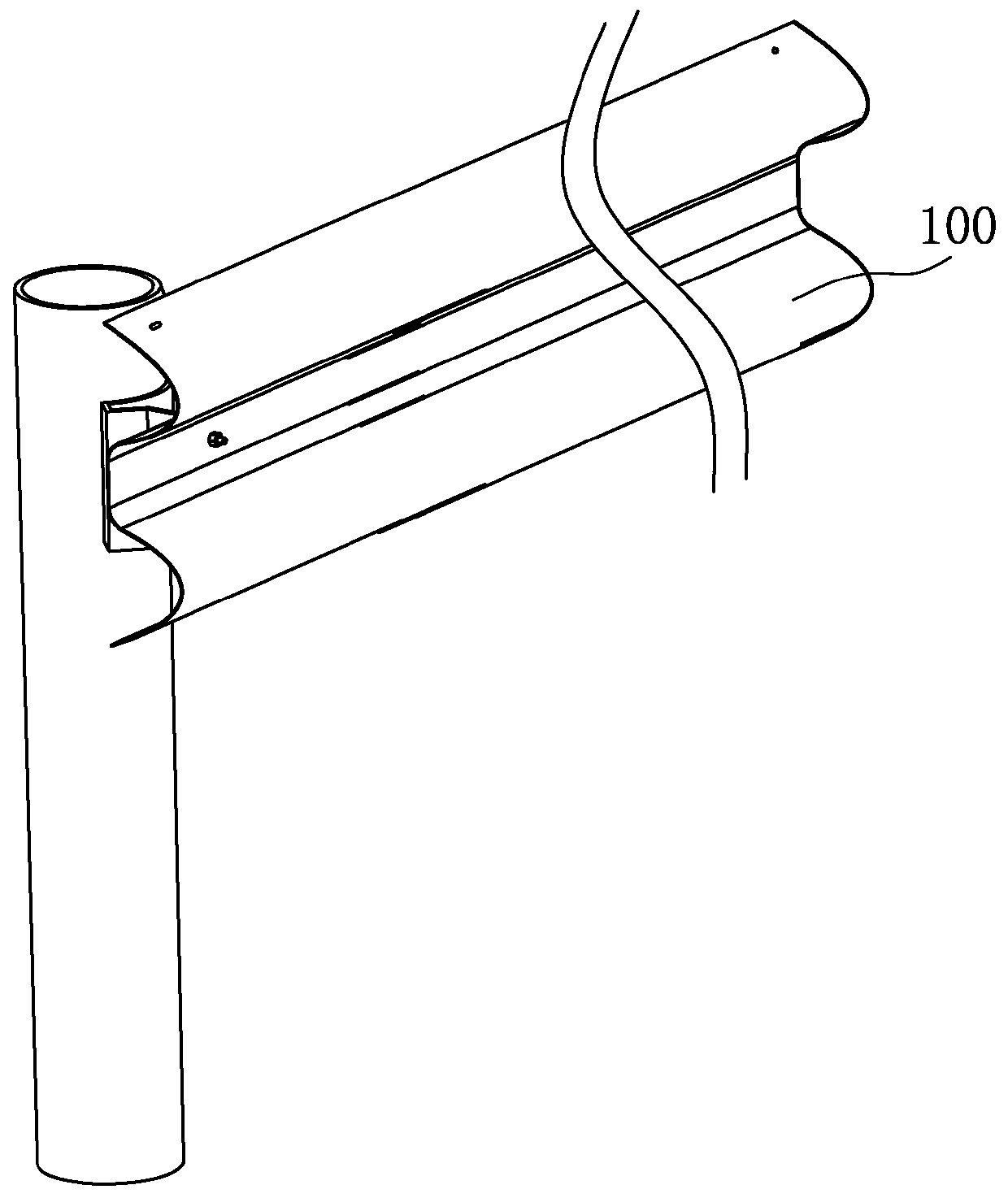

[0072] refer to Figure 27 , the corrugated plate 100, as a preferred method, the most common one is a W-shaped double-wave corrugated plate, and a mounting part is arranged in the center, which is made of a steel plate after 5 mm, and is formed by multiple pressure rolls. And the surface is anti-corrosion. A further beneficial design is that an inward flange 110 is provided at the upper and lower edges of the corrugated plate 100, or it is called a be...

Embodiment 2

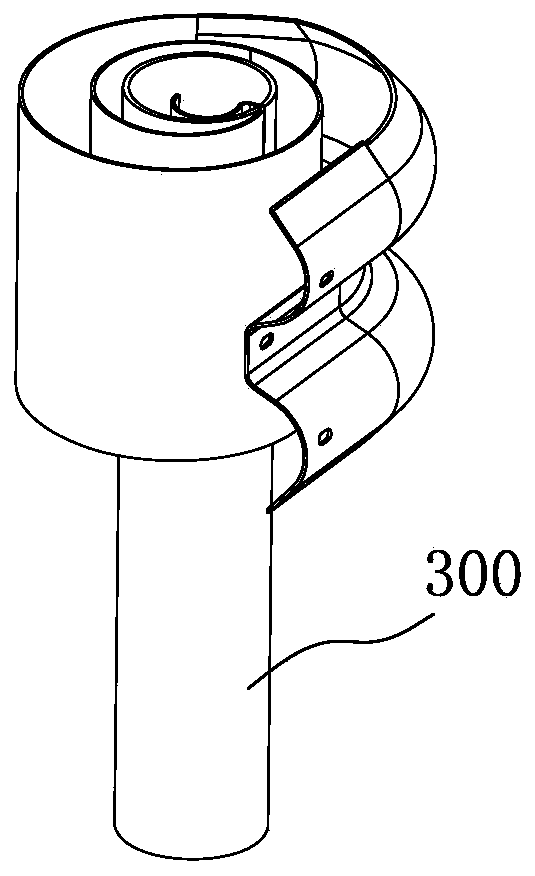

[0096] refer to Figure 16 to Figure 18 , this embodiment improves the structure of the damping elastic member. Specifically, the difference from the first embodiment is that the helical part of the damping elastic member itself is also a helical shape rolled by a corrugated plate, that is, the helical part and the installation The metal sections of the parts are the same, all of which are W-shaped. This structure has better elastic properties, and the impact resistance and energy absorption effects are better than those of the examples. Of course, its manufacturing difficulty and manufacturing cost are relatively high, and it can preferably be applied to accident-prone road sections.

[0097] In this embodiment, elastic fillers, thin-walled steel pipes, etc. used to increase the performance of the damping elastic member are still applicable.

[0098] Further, in this embodiment, reversely bent W-shaped corrugated plates can be filled in the spiral gap 250 to form fillers to ...

Embodiment 3

[0100] refer to Figure 23 , Figure 25 , in this embodiment, the biggest difference from Embodiment 1 is that it is set in pairs. In some accident-prone places, especially heavy-duty truck accident-prone places, traditional columns and guardrails are vulnerable under the impact of heavy trucks, causing vehicles to rush out of the guardrail, which aggravates the occurrence of secondary accidents. In this embodiment, the traditional single column is changed to double column, that is to say, Figure 23 The double uprights are used to replace the traditional one upright. Two uprights are arranged close to each other, and a damping elastic part is installed on the double uprights. The specific style of the damping elastic part is as follows:

[0101] The damping elastic member includes two symmetrically arranged single-screw mechanisms, that is, a helical part 230 and a buckle structure 210 are respectively arranged in each helix, and a corrugated part 220 is formed between the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com