Construction method of three-dimensional rigid foundation pit supporting structure

A technology of foundation pit support and three-dimensional rigidity, which is applied in basic structure engineering, excavation, sheet pile wall, etc., can solve the problems of difficult construction, complicated procedures and high construction cost, and achieve the effect of shortening construction period, increasing work efficiency and reducing construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

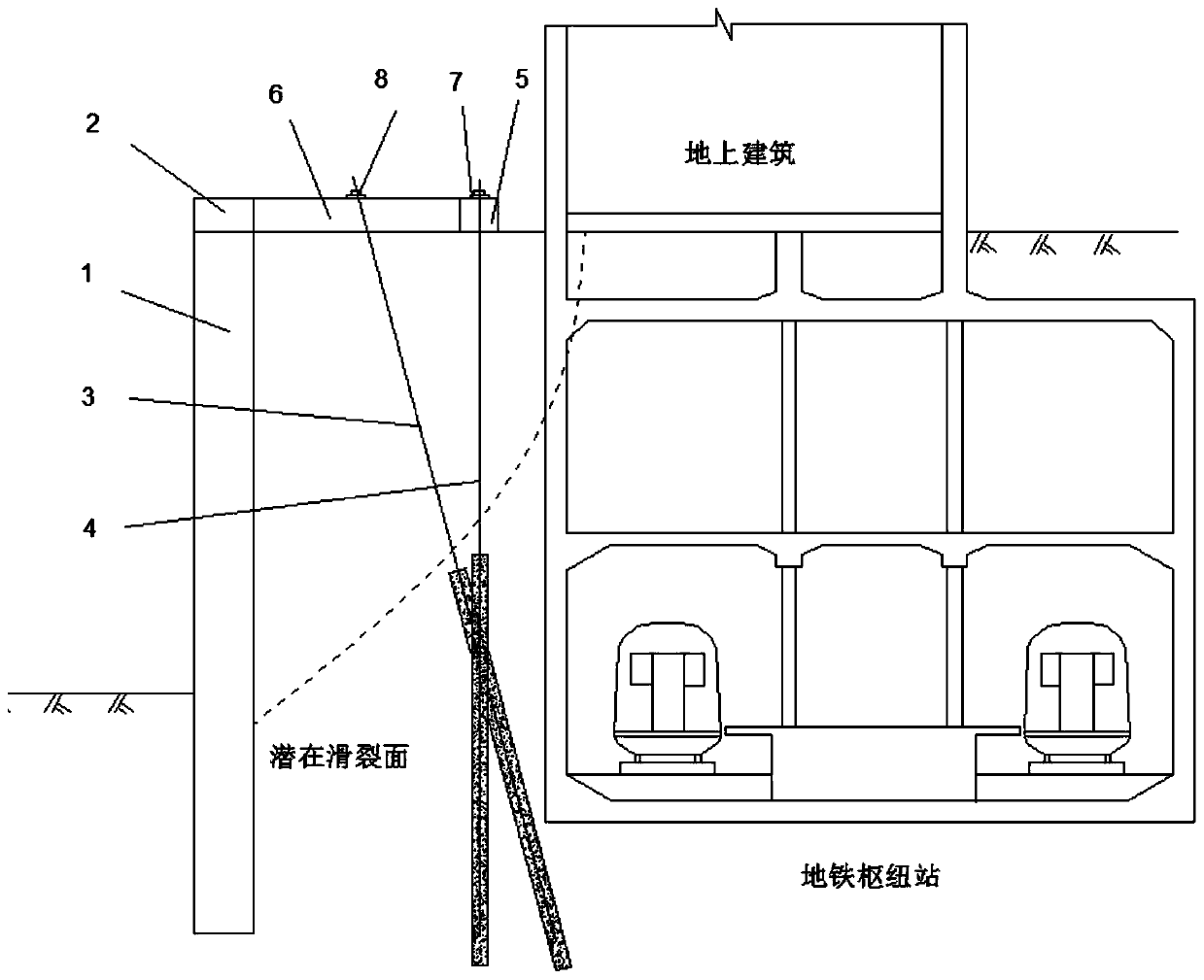

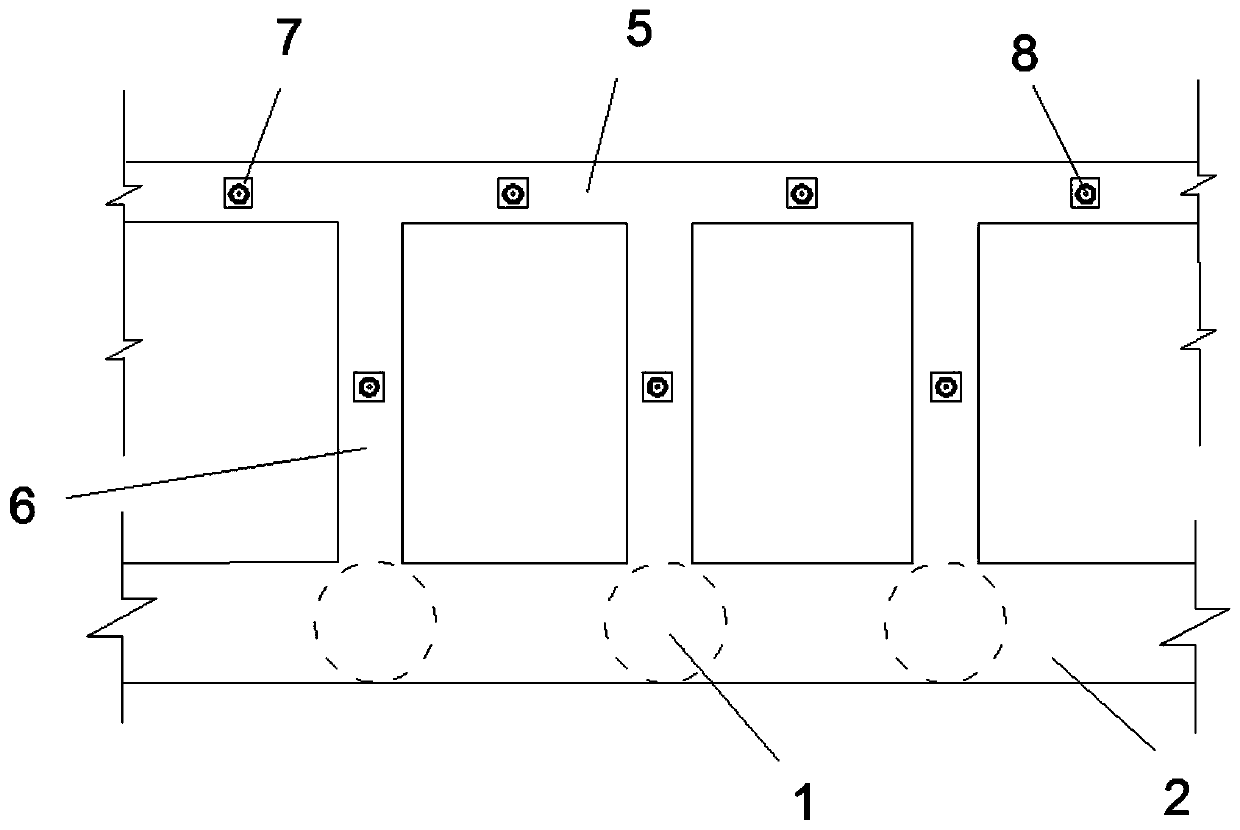

[0034] Such as Figure 1-2 As shown, a three-dimensional rigid foundation pit support structure includes the front row of retaining piles 1, the middle row of oblique prestressed anchor rods 3 and the rear row of vertical prestressed anchor rods 4, and the front row of retaining piles 1 is set in the foundation pit At the wall, the rear row of vertical prestressed anchor rods 4 are distributed longitudinally parallel to the front row of retaining piles 1, the top of the front row of retaining piles 1 is connected with the front row of retaining pile crown beams 2, and the upper part of the rear row of vertical prestressed anchor rods 4 The vertical anchor longitudinal beam 5 of the rear row is connected, and the cantilever beam 6 is connected between the crown beam 2 of the front row retaining pile and the vertical anchor longitudinal beam 5 of the rear row, and the crown beam 2 of the front row retaining pile, the vertical anchor longitudinal beam 5 of the rear row and The ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com