Compressor fixing assembly and compressor

A technology for fixing components and compressors, applied in the field of compressors, can solve problems such as the limitation of vibration reduction and vibration isolation effects, and achieve the effects of reducing internal stress, improving vibration isolation and vibration reduction effects, and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

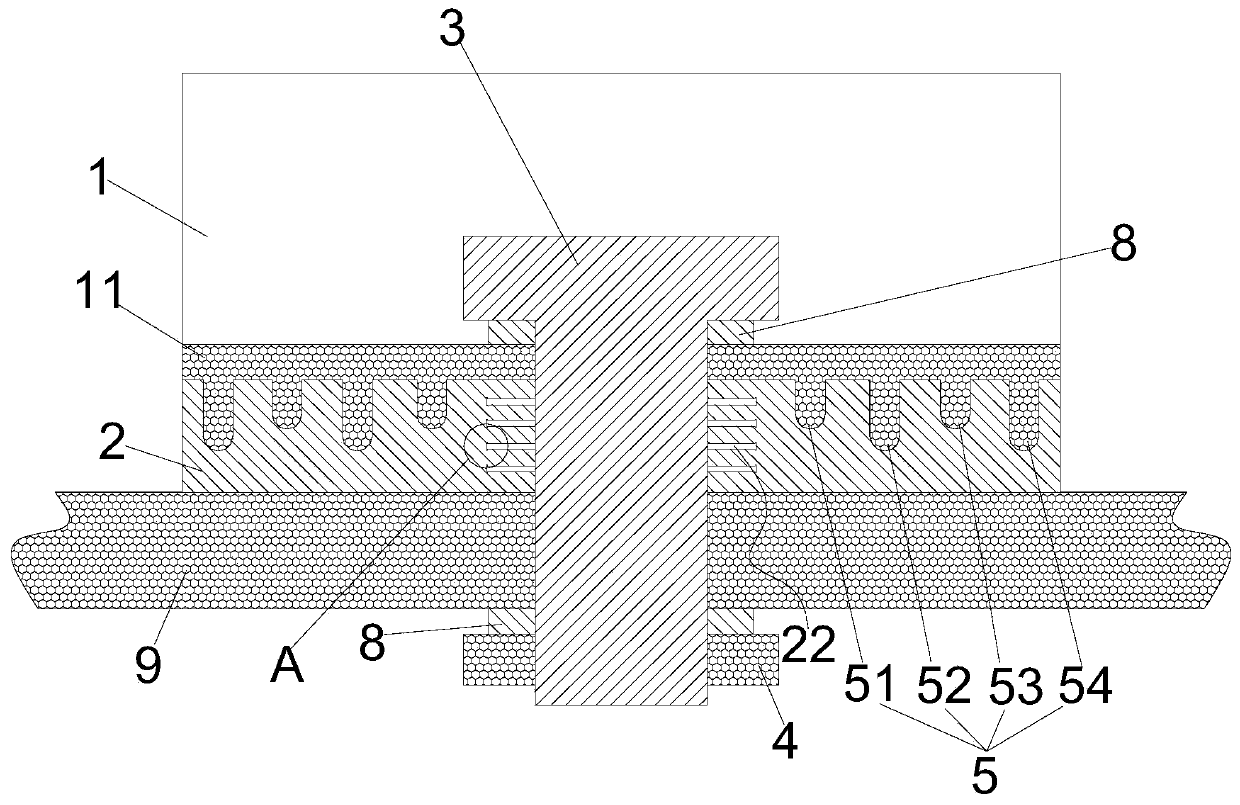

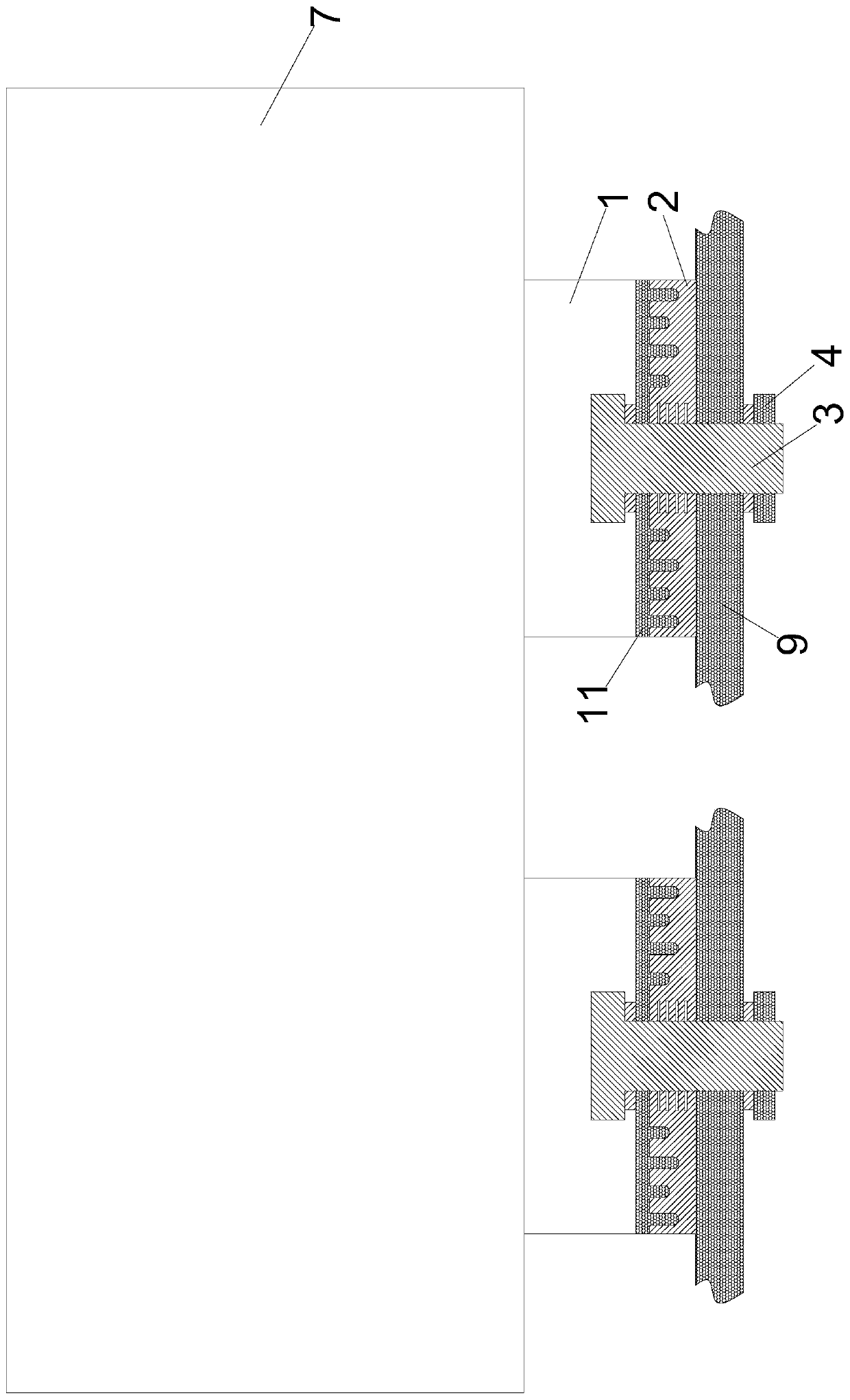

[0037] This embodiment provides a compressor fixing assembly for fixing and installing a compressor, including a foot 1, a rubber pad 2, a screw 3 and a nut 4. The foot 1 is fixed on the body 7 of the compressor and the foot 1 is compatible with The body 7 of the compressor is an integral structure, and the support foot 1 at least includes a flat plate 11, the flat plate 11 is provided with a first through hole 12, and the rubber pad 2 is provided with a second through hole 21, and the rubber pad 2 is in the shape of a square .

[0038] During installation, the above-mentioned plate 11 is overlapped on the rubber pad 2, that is, the rubber pad 2 is placed under the above-mentioned plate 11, and the first through hole 12 and the second through hole 21 are facing each other, and the screws 3 pass through the first through hole in turn. The hole 12 and the second through hole 21 are then screwed to the nut 4 . More preferably, a washer 8 is provided between the nut 4 and the rubb...

Embodiment 2

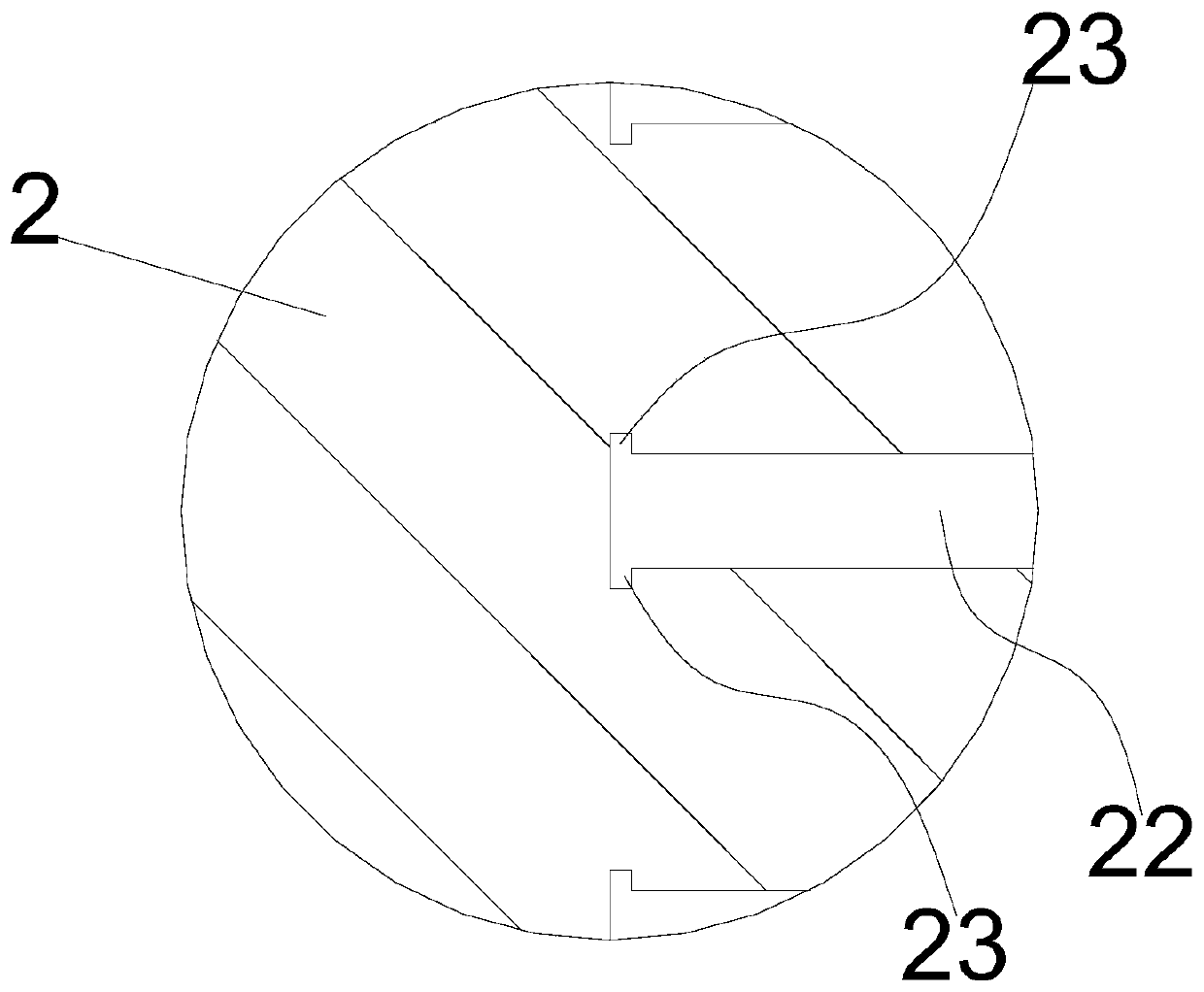

[0042] This embodiment serves as a specific implementation of Embodiment 1. The several protrusions 5 in the compressor fixing assembly provided by this embodiment are divided into an inner group and an outer group, and the inner group has a plurality of protrusions 5 Sector-shaped protrusions, a plurality of sector-shaped protrusions are equidistantly distributed and surround a first ring 51, and the first ring 51 is coaxial with the first through hole 12. Optimally, the number of the above-mentioned sector-shaped protrusions is four , the central angle of each fan-shaped bump is 45°.

[0043] The ravine 6 on the above-mentioned rubber pad 2 includes a first groove adapted to the above-mentioned first ring 51, the first groove includes four fan-shaped grooves, and the four fan-shaped protrusions of the above-mentioned first ring 51 are respectively embedded in four In the fan-shaped groove, in this way, the vibration of the support foot 1 can be transmitted to the first groov...

Embodiment 3

[0046] This embodiment is a best implementation mode of the above-mentioned embodiment. In this embodiment, there are also multiple ring-shaped bumps, and the diameters of the multiple ring-shaped bumps increase sequentially from inside to outside. Optimally, the number of the above-mentioned ring-shaped protrusions is three, and the order from inside to outside is the second ring 52, the third ring 53 and the fourth ring 54. The height is a, the height of the second ring 52 is b, the height of the third ring 53 is c, and the height of the fourth ring 54 is d, wherein a=c, b=d, d>c. In this case, the above-mentioned second groove also includes three circular grooves, and the function of each circular groove can also reduce the effect of vibration transmitted along the radial direction of the rubber pad 2 .

[0047] With this structure, all the protrusions 5 form a wave-shaped structure from the outside to the inside, so that when subjected to vibration, each ring is limited by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com