Plastic photovoltaic support with intelligent waste heat recovery function

A waste heat recovery, photovoltaic support technology, applied in the support structure of photovoltaic modules, photovoltaic modules, photovoltaic power generation and other directions, can solve the problems of rapid and low-cost installation of photovoltaic projects, power generation efficiency photovoltaic power station migration, long occupation period, power generation efficiency decline, etc. problems, to achieve the effect of saving installation time and labor consumption, saving time and financial resources, and improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

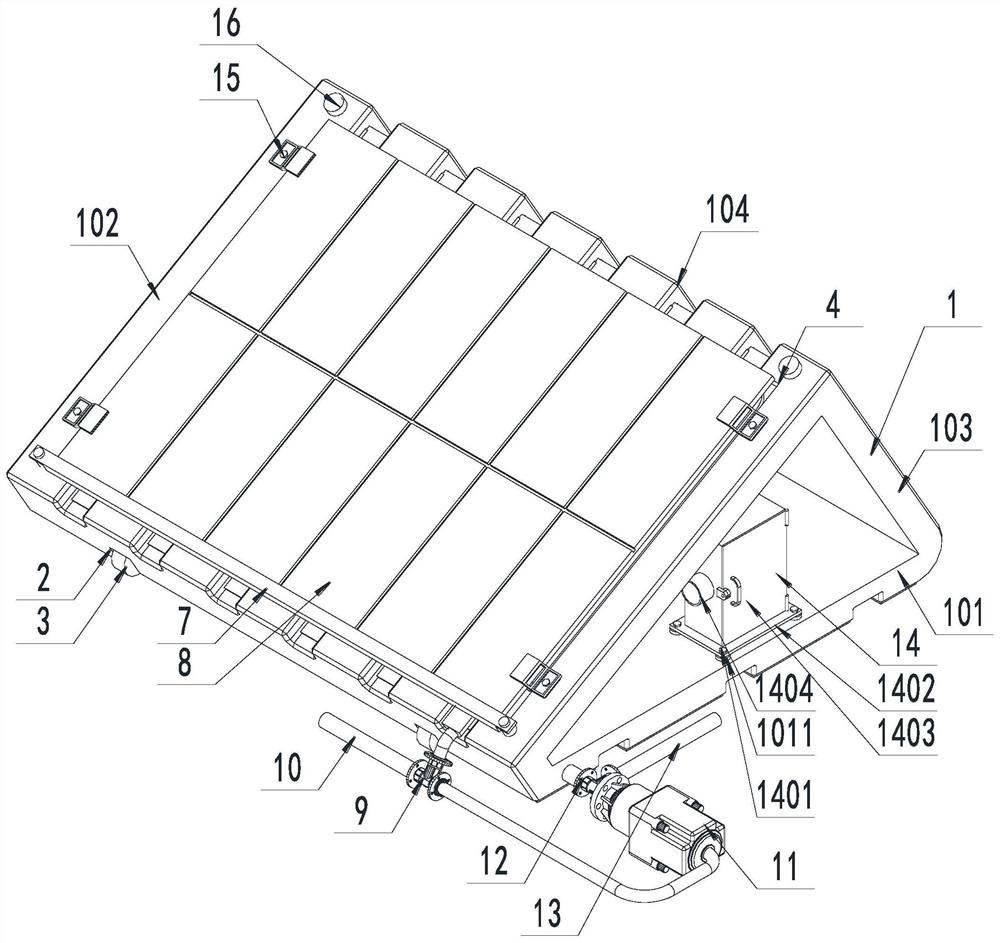

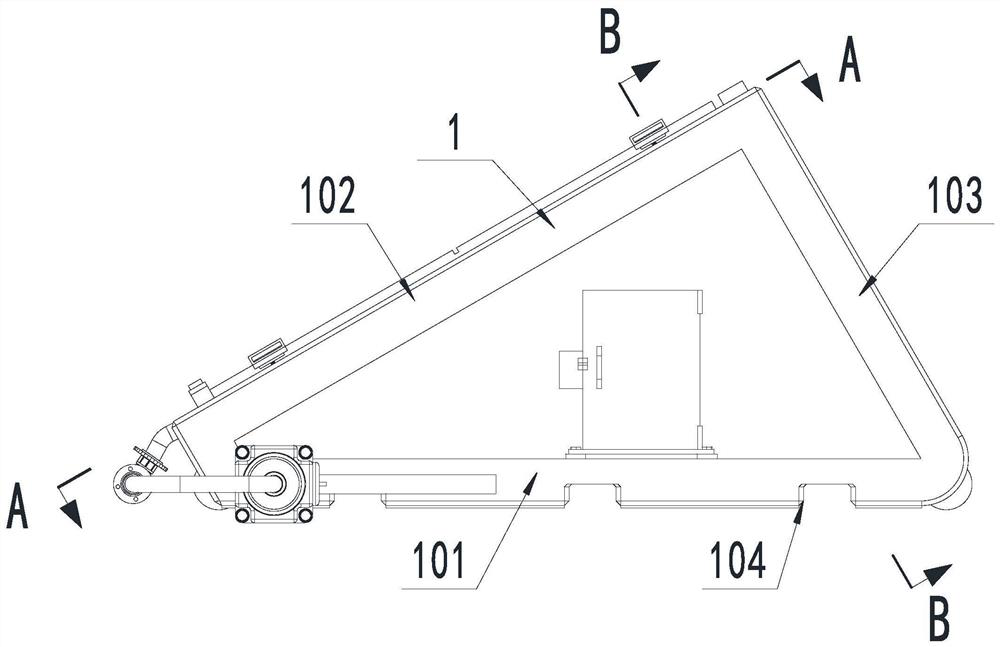

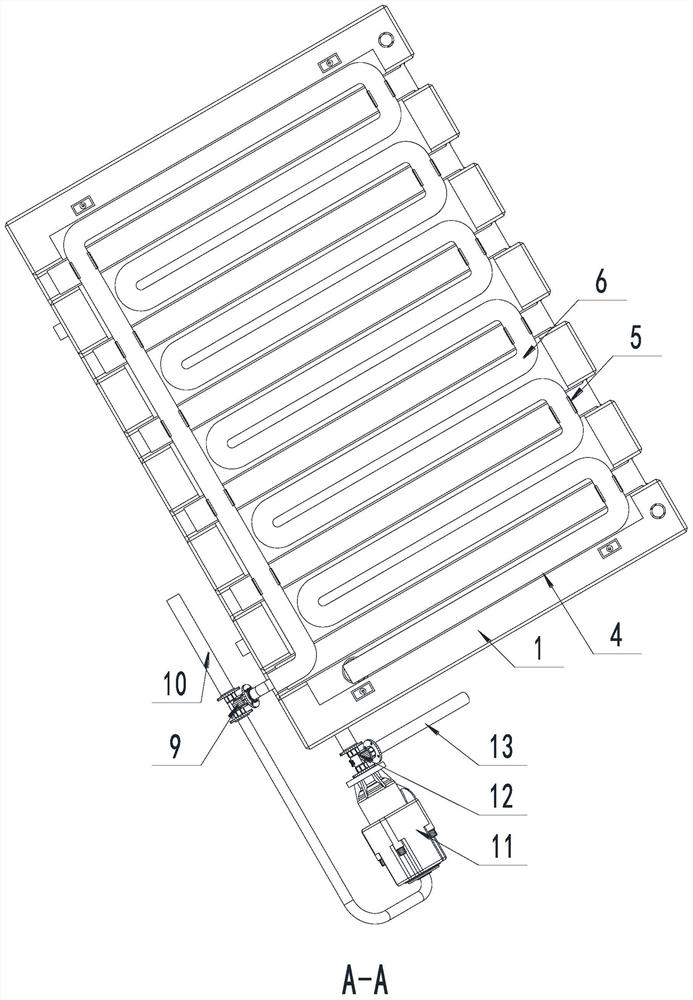

[0038] Such as Figure 1-6As shown, a plastic photovoltaic support with intelligent waste heat recovery function proposed by an embodiment of the present invention includes a triangular water tank support 1. The overall material of the triangular water tank support 1 is plastic material, and its internal structure has a cavity, which can be used The overall weight of the device is adjusted by adding water source. There is no need to add water source during installation. The whole device is light and easy to carry to the roof. There is no need to consider the weather to draw lines and cast molds to install steel brackets, saving installation time and manpower co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com