A non-contact high-precision liquid level detection system and its detection method

A liquid level detection, non-contact technology, applied in the direction of displaying liquid level indicator through pressure measurement, can solve the problems of large detection error and inability to work normally in high temperature environment, achieve high precision, wide applicability, guarantee The effect of dispensing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention is further described in conjunction with the following examples.

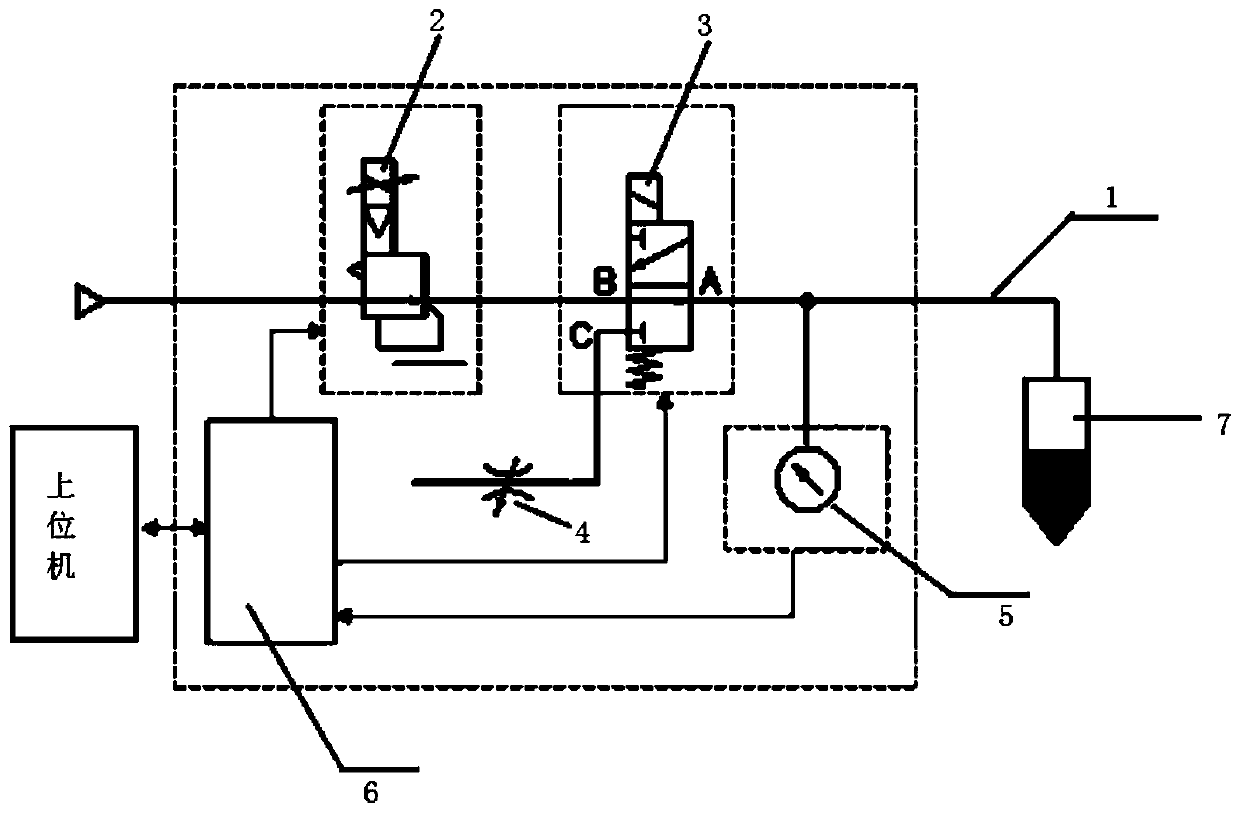

[0050] figure 1 A non-contact high-precision liquid level detection system is shown, the liquid level detection system includes: gas supply pipeline 1 electric proportional valve 2, solenoid valve 3, throttle valve 4, pressure sensing module 5 and processing module 6. Among them, one end of the gas supply pipeline 1 is connected to the airtight container 7 to be tested, and the other end of the gas supply pipeline 1 is connected to the gas source. Set near the side of the air source.

[0051] The processing module 6 is respectively connected with the electric proportional valve 2 , the solenoid valve 3 and the pressure sensing module 5 . The processing module 6 is used to control the energization and de-energization of the coil of the solenoid valve 3, and is also used to control the electric proportional valve 2, so as to realize the regulation of the input air source pressure by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com