Low-temperature gas liquefaction device

A low-temperature gas and liquefaction device technology, applied in liquefaction, refrigeration, liquefaction, solidification, etc., can solve problems such as insufficient utilization of cooling capacity, large heat transfer temperature difference, and difficult production of cylinder heat exchangers, etc., to achieve cooling capacity utilization efficiency High, high liquefaction rate, the effect of avoiding heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

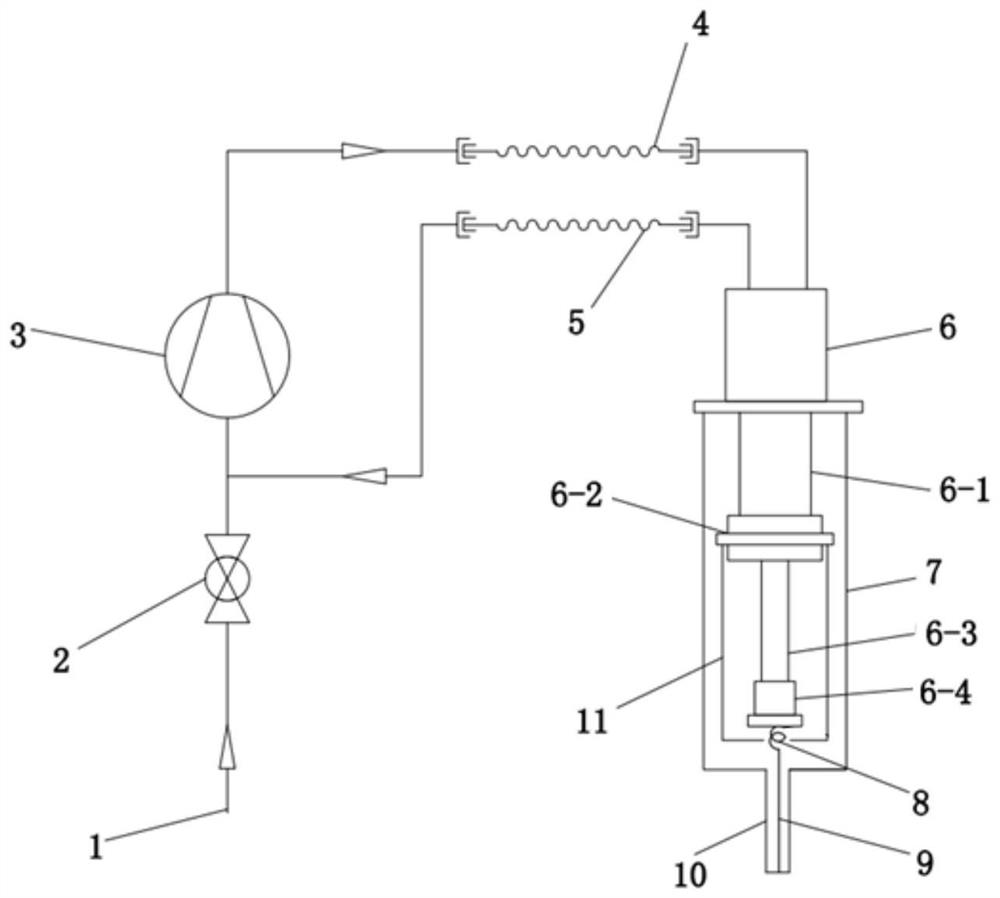

[0020] like figure 1 In the shown low-temperature gas liquefaction device, the refrigerator 6 is a two-stage refrigerator, which is integrated in the vacuum enclosure 7 as a cold source. A cold shield 11 is arranged inside the vacuum cover 7, and the cold shield 11 is connected to the first-stage cold head 6-2 for cooling, so that the temperature of the cold shield 11 is maintained between 20-100K. The bottom of the secondary cylinder 6-3 has holes and is connected with the low temperature throttle device 8. In the liquefaction stage, after the low-temperature gas at the bottom of the secondary cylinder 6-3 is throttled by the low-temperature throttling device 8, the low-temperature liquid is obtained, and is output to the low-temperature liquid storage container through the infusion pipe 9. The vacuum cannula 10 is wrapped. The consumption of the liquefaction process is supplemented by the high-purity gas provided externally, and the high-purity gas is supplemented by the s...

Embodiment 2

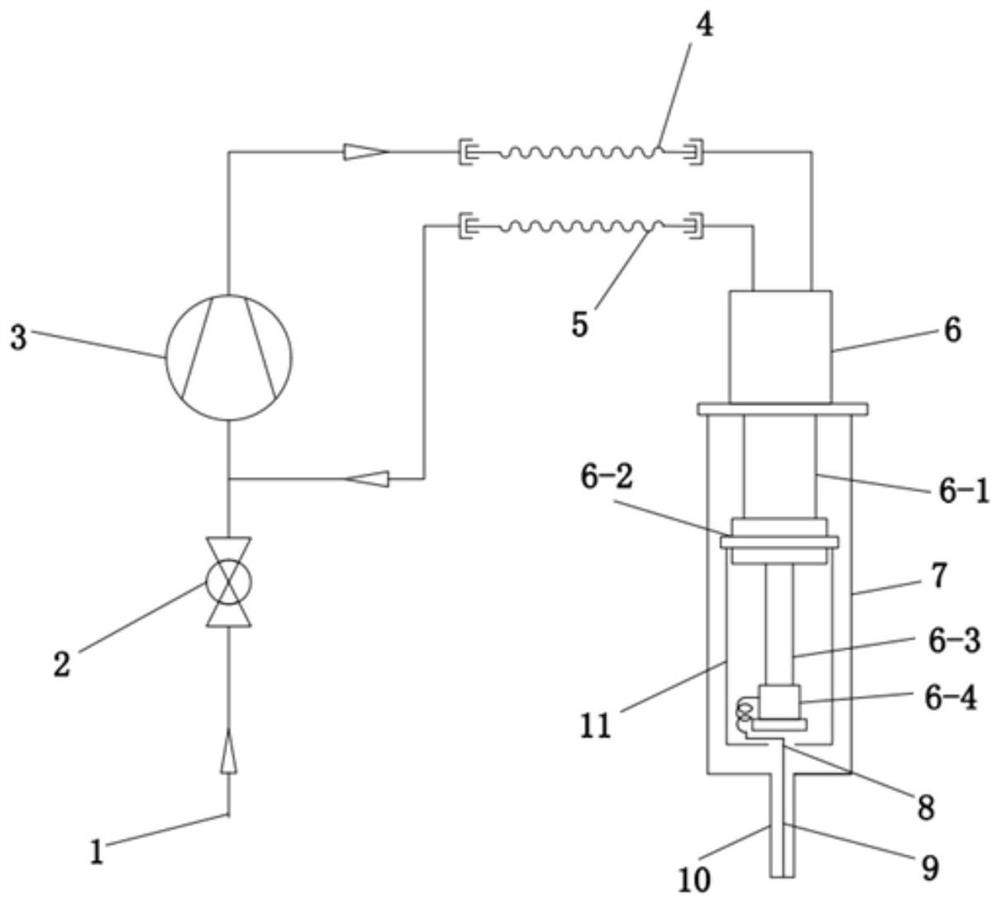

[0022] like figure 2 As shown, the second embodiment is basically the same as the first embodiment, the difference is that a hole is opened in the low temperature part of the secondary cylinder 6-3 near the bottom, and a low temperature throttle device 8 is connected.

Embodiment 3

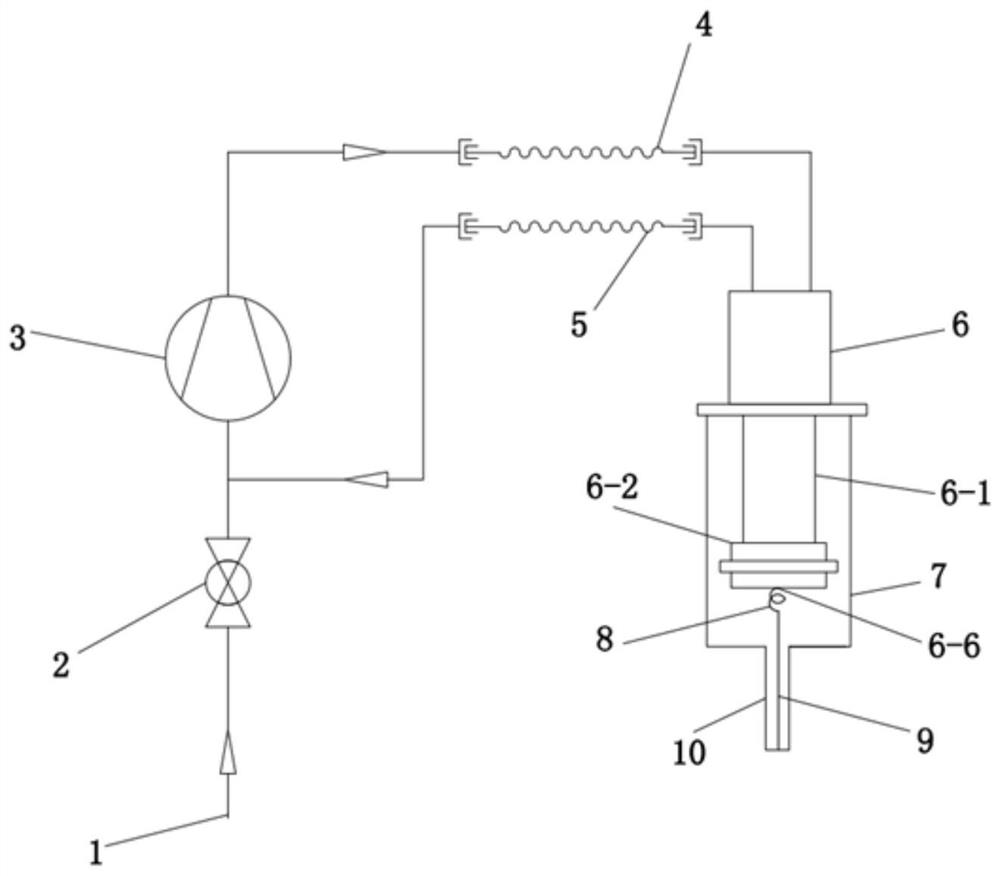

[0024] like image 3 As shown, the third embodiment is basically the same as the first embodiment, except that the refrigerator 6 is a single-stage refrigerator, and the bottom of the first-stage cylinder 6-1 has a hole and is connected to the low-temperature throttling device 8. At the same time, no cold shield 11 is provided in the vacuum hood 7 .

[0025] When the above embodiments are specifically implemented, the refrigerator may be a GM refrigerator, a pulse tube refrigerator, or a Stirling refrigerator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com