Reverse starting test method and device for traction system

A traction system and test method technology, applied in the field of electric drive vehicle test, can solve the problems of complex test operation, high test cost, inconvenient timely adjustment, etc., to achieve the effect of ensuring performance and saving test resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

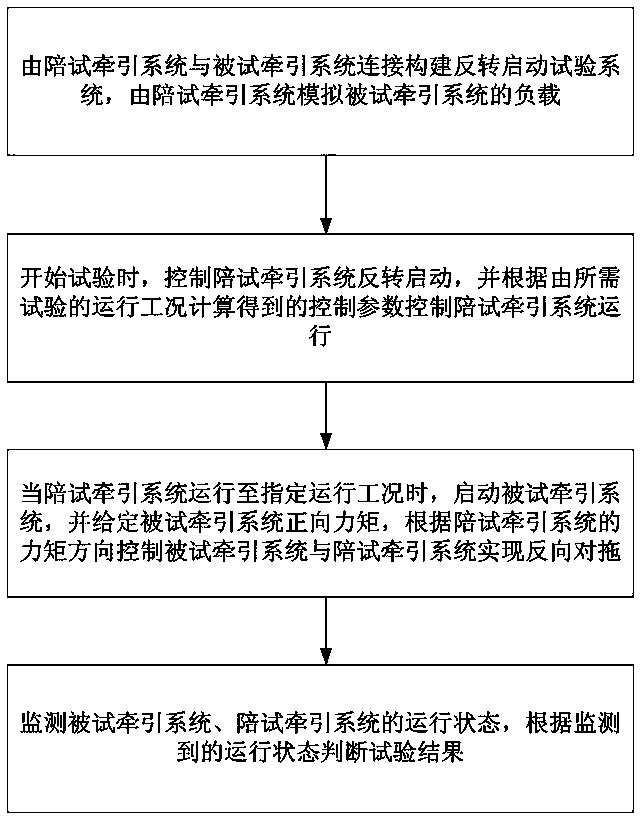

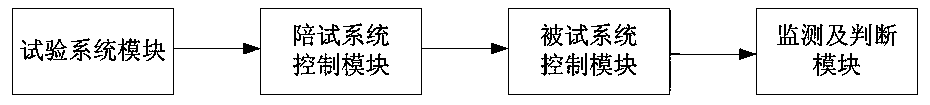

[0047] Such as figure 1 As shown, the steps of the test method for reverse start of the traction system in this embodiment include:

[0048] S1. Construct a reverse start test system by connecting the traction system under test with the traction system under test, in which the traction system under test simulates the load of the traction system under test;

[0049] S2. When starting the test, control the traction system of the accompanying test to start in reverse, and control the operation of the traction system of the accompanying test according to the control parameters calculated from the operating conditions of the required test;

[0050] S3. When the traction system under test runs to the specified operating condition, start the traction system under test, and give the positive torque of the traction system under test, and control the distance between the traction system and the traction system under test according to the torque direction of the traction system under tes...

Embodiment 2

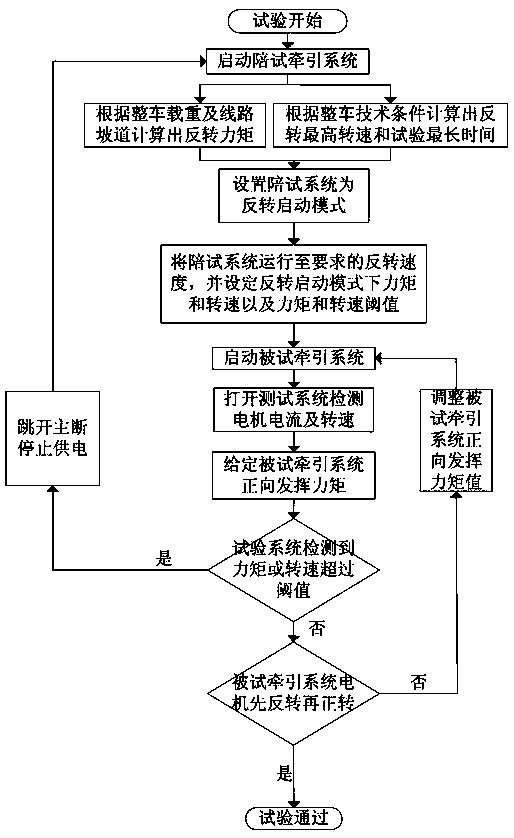

[0084] Such as Figure 4 As shown, the process of implementing the reverse start test by applying the method of Embodiment 1 in this embodiment is as follows:

[0085] ①Start the test traction system, and the simulation software of the control computer of the test traction system calculates the reverse torque according to the load of the vehicle and the slope of the line, and calculates the maximum reverse speed and the longest start time according to the technical requirements;

[0086] ② Input the reverse torque and maximum speed conditions into the test traction system, and run the test traction system in the constant torque mode, and the test system is in the reverse idling state at this time;

[0087] ③ Run the accompanying test system to the required reverse speed, and set the torque and speed and the threshold of torque and speed in the above mode to ensure the safe operation of the test system; open the test bench test system to monitor the motor current and speed;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com