Pipeline system for directly observing influence of nanoparticles on detonation limit

A technology of nano-particles and pipeline systems, which is applied in the field of detonation tests, can solve the problems of unclear detonation attenuation and achieve good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0015] The invention provides a piping system for directly observing the effect of nanoparticles on the detonation limit.

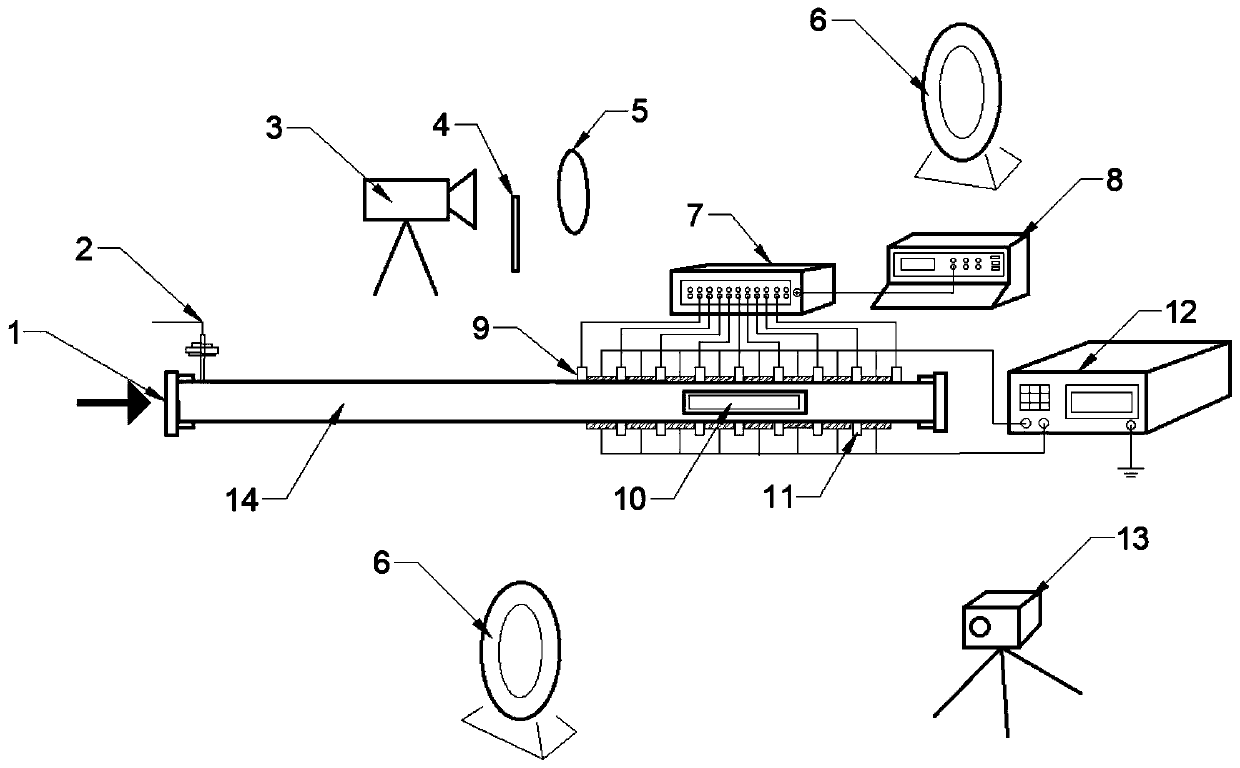

[0016] Such as figure 1 As shown, the system includes a high-voltage ignition system 2, a high-speed camera 3, a shading sheet 4, a convex lens 5, a concave mirror 6, a data box 7, a digital display recorder 8, a sensor 9, an observation window 10, a magnetic bead blowing device 11, A magnetic field generating system 12, a parallel light source 13 and a detonation tube 14, the front end of the detonation tube 14 is a premixed gas inlet 1, a high-voltage ignition system 2 is installed at the premixed gas inlet 1, and a sensor 9 and a sensor 9 are installed on the opening of the detonation tube 14 The data box 7 is connected to the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com