Pressure stabilizing system for detecting internal leakage amount of valve

A technology for testing valves and valves. It is applied in the direction of measuring the increase and decrease rate of fluid, measuring devices, and liquid tightness measurement by using liquid/vacuum degree. , to achieve the effect of increasing pipeline pressure and increasing buffer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

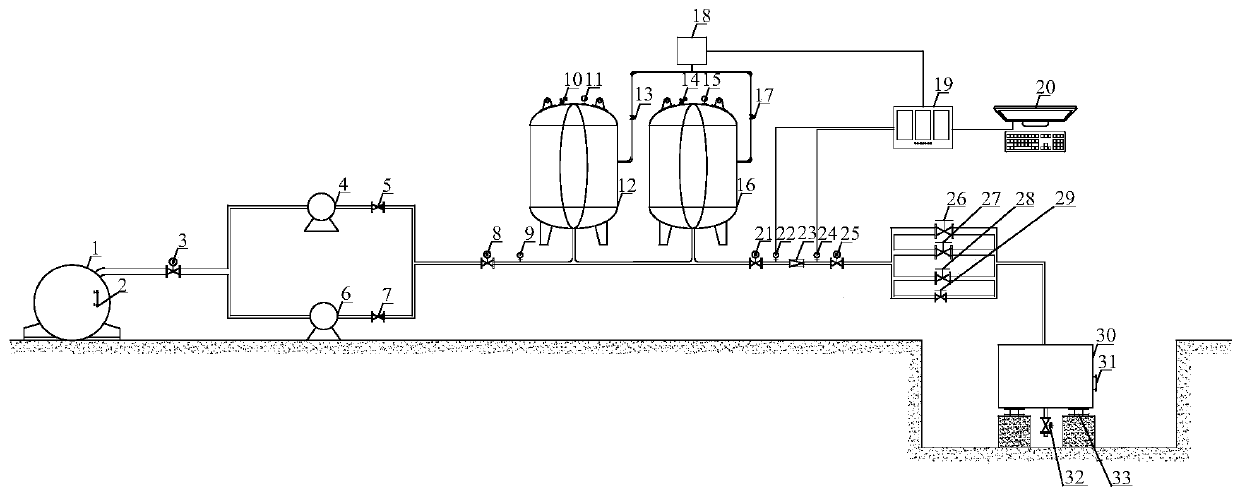

[0032] Such as figure 1 As shown, the pressure stabilizing system for detecting internal leakage of the valve according to the present invention includes a water tank 1, a first electric valve 3, a plunger pump 4, a centrifugal pump 6, a first check valve 5, and a second check valve. Valve 7, the first airbag type surge tank 12, the second airbag type surge tank 16, the compressor 18, the pressure controller 19, the pilot pressure reducing valve 23, the first test valve 26, the second test valve 27, the first Three test valves 28, a fourth test valve 29 and a collection device 30. The outlet of the water tank 1 is connected with the first electric valve 3, and the outlet of the first electric valve 3 is divided into two routes, one of which is connected with the plunger ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com