Fluent-based multi-way valve simulation analysis and structure optimization method

A technology of simulation analysis and optimization method, applied in the direction of design optimization/simulation, geometric CAD, etc., can solve the high cost of valve core and valve body design and manufacturing, cannot simulate the flow field in the valve realistically, and is difficult to optimize the analysis of the component structure and experimental issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific examples.

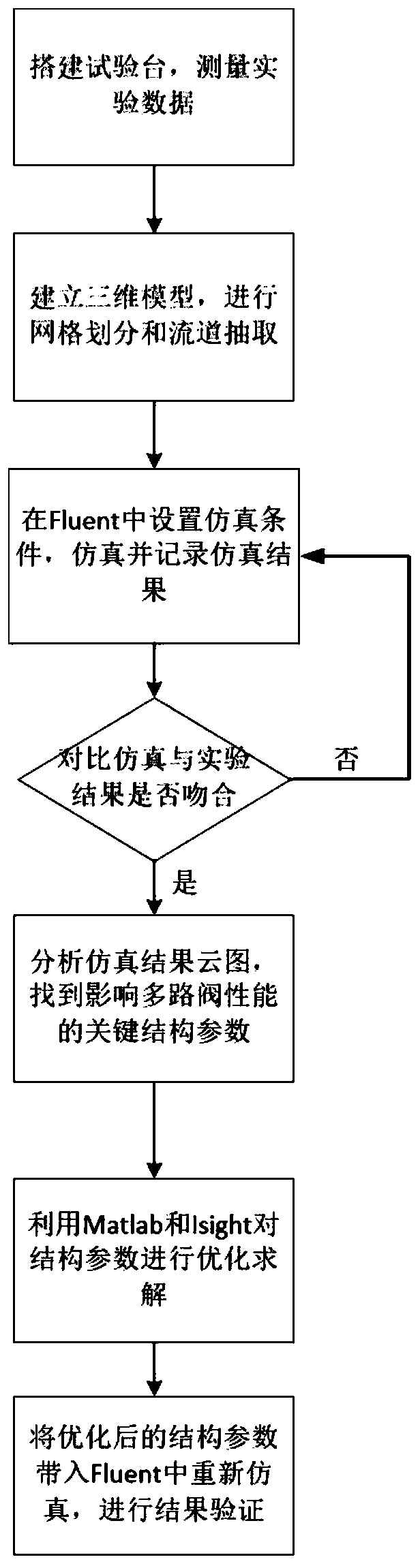

[0025] A Fluent-based multi-way valve simulation analysis and structural optimization method, including the following steps:

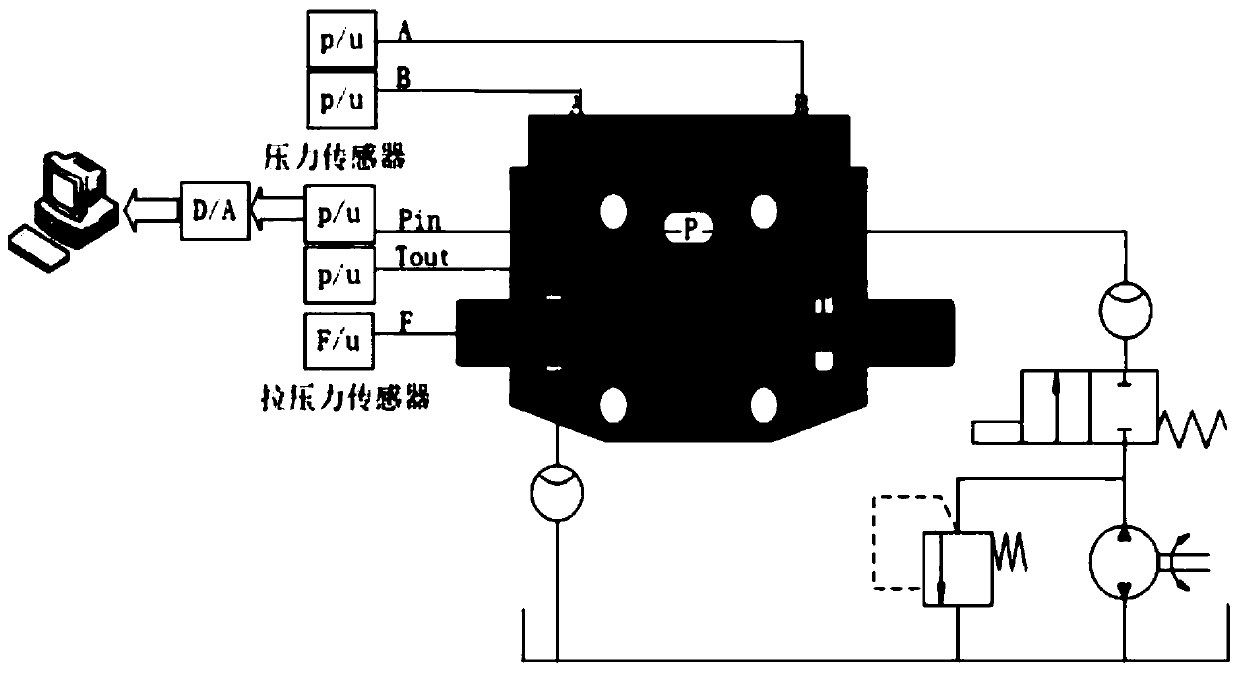

[0026] Step 1: Conduct experimental tests on the hydraulic power and pressure loss of the multi-way valve

[0027] Build a hydraulic test circuit on the multi-way valve test bench. The equipment needed in the experiment is multi-way valve, tension pressure sensor, power source, connecting pipeline, turbine flowmeter, and pressure sensor. A total of four pressure measuring points were set up in the experiment, and the pressure conditions at the four positions of the valves P, T, A, and B were measured respectively. During the experiment, a no-load connection is adopted between A and B. The pull pressure sensor is directly connected with the spool and fixed, adjusts and fixes the opening of the valve port by means of screw feed, and measures the hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com