Operating method for automatic transmission of motor vehicle

A technology of automatic transmission and operation method, applied in the direction of brakes, brake components, mechanical equipment, etc., can solve the problems of damage, parts wear and driving comfort, and achieve the effect of reducing parts wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

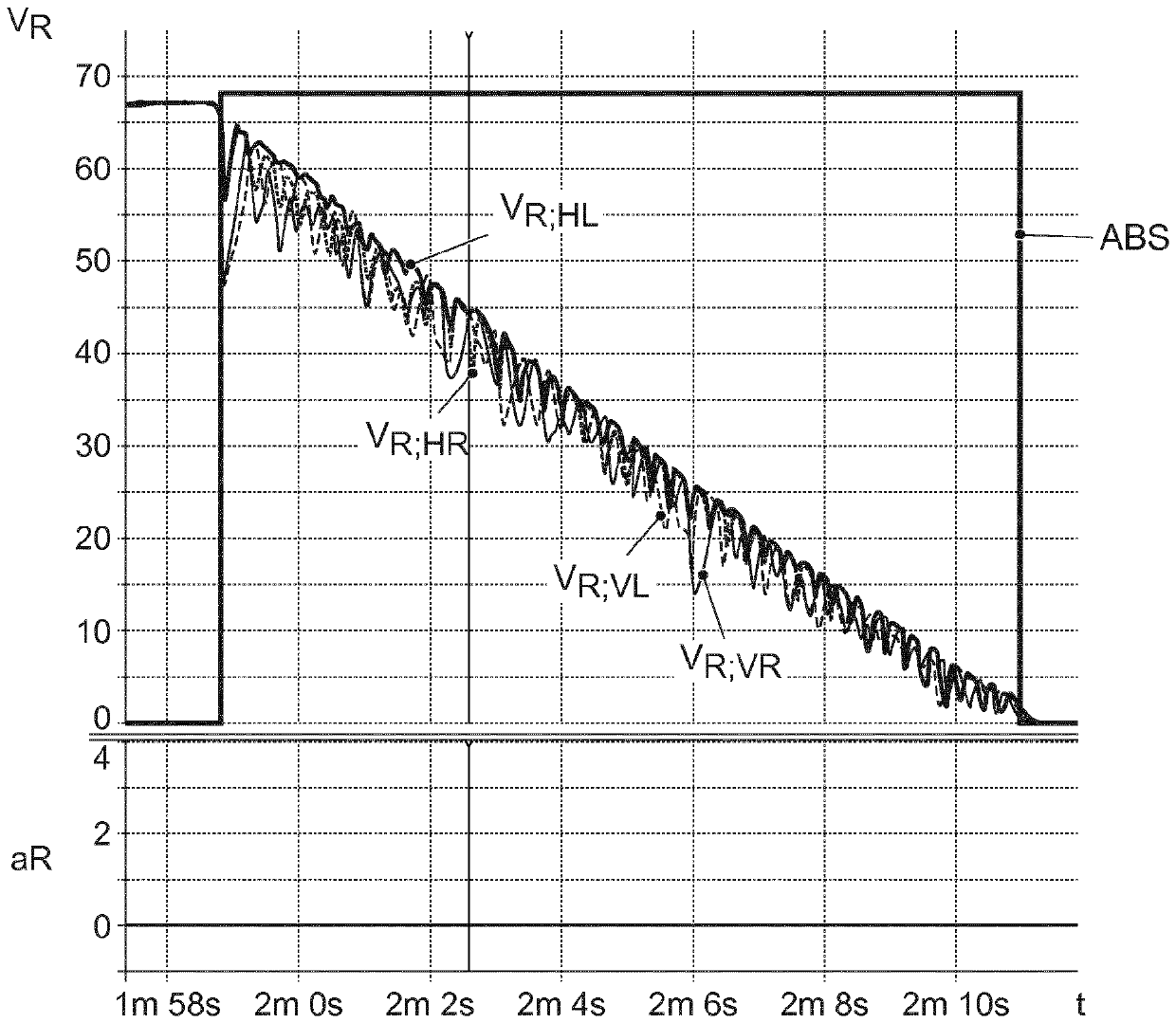

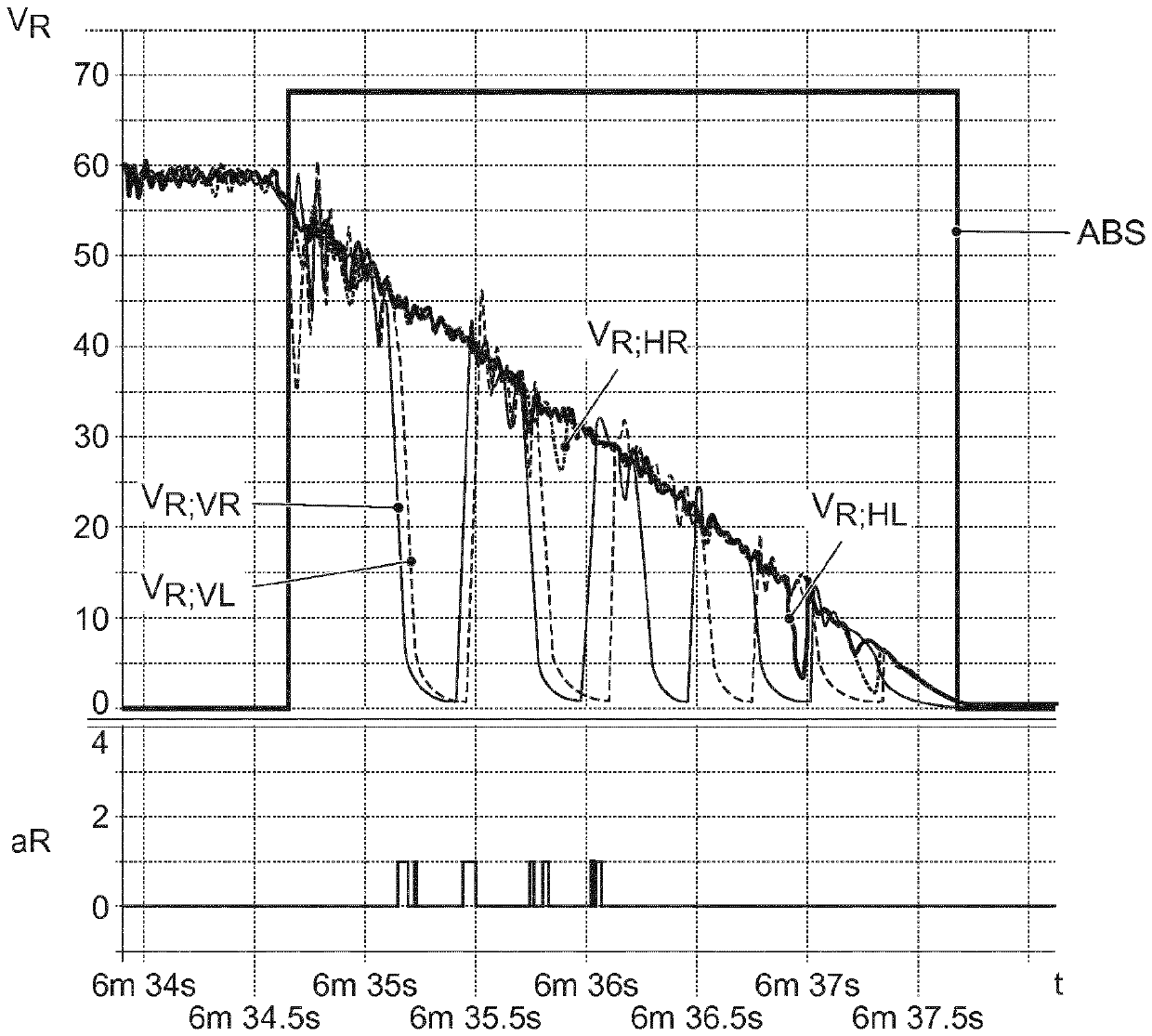

[0049] figure 1 with 2 Correspondingly, in the upper window is shown a diagram for illustrating the wheel speed gradient during braking by means of the active anti-lock braking system ABS, in which the left and right front wheels v of the motor vehicle R,VL ,v R,VR and the left and right rear wheels v R,HL ,v R,HR wheel speed v R, v R,VL ,v R,VR ,v R,HL ,v R,HR Relative time t is plotted.

[0050] In the lower window, figure 1 with 2 Accordingly, there is a diagram in which the state of lift of the driven wheel aR is plotted against time t.

[0051] here, figure 1 ABS braking without wheel lift is shown.

[0052] here, figure 2 is shown in which the driven front wheels on the left and right sides of the vehicle are braked by the ABS of the lane lift and is illustrated as follows, that is, in the case of a lift of the driven wheel aR,

[0053] - its wheel speed v R,VL ,v R,VR At a certain speed value less than, for example, based on the unraised and / or undrive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com