Flat-jet fuel injector for an aircraft turbine engine

A technology of turbine engine and fuel injector, which is applied in the directions of injection device, liquid injection device, burner, etc., can solve the problem of expensive micro-catheter, and achieve the effects of simplifying manufacturing, improving manufacturability, and simplifying manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

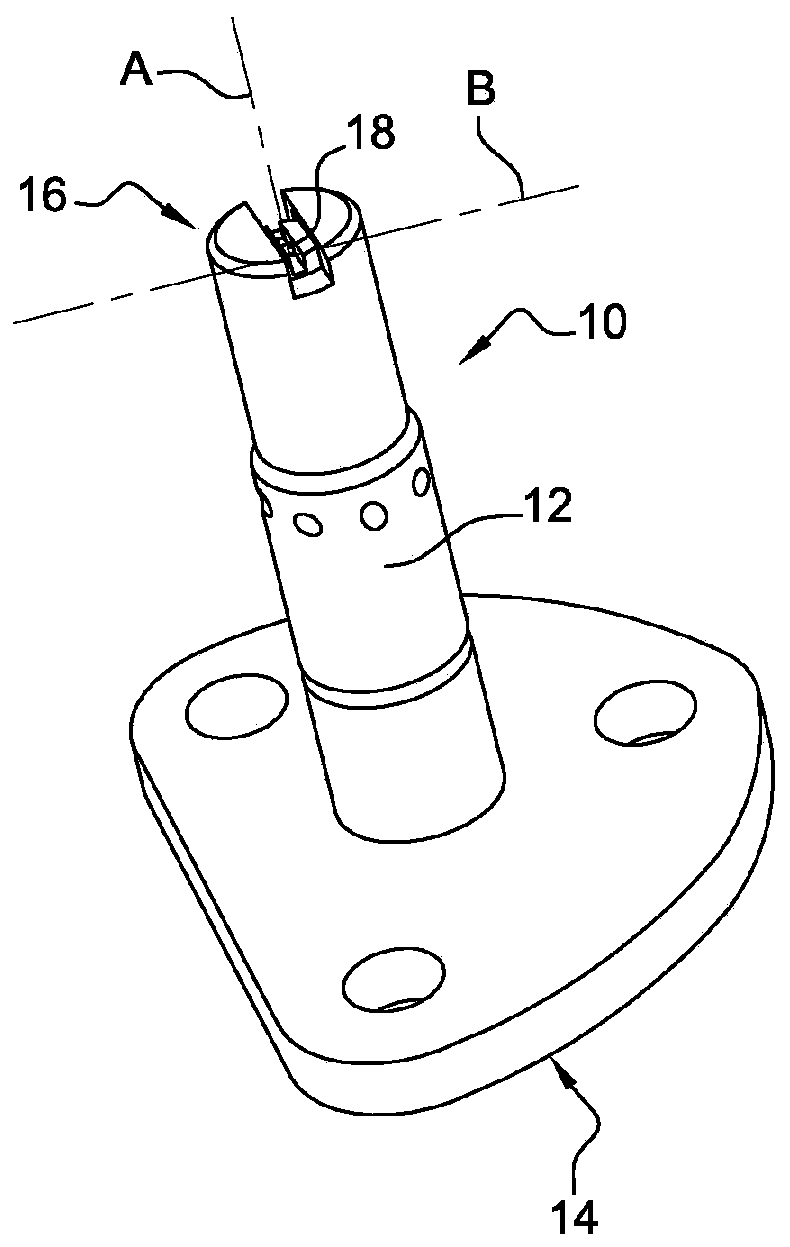

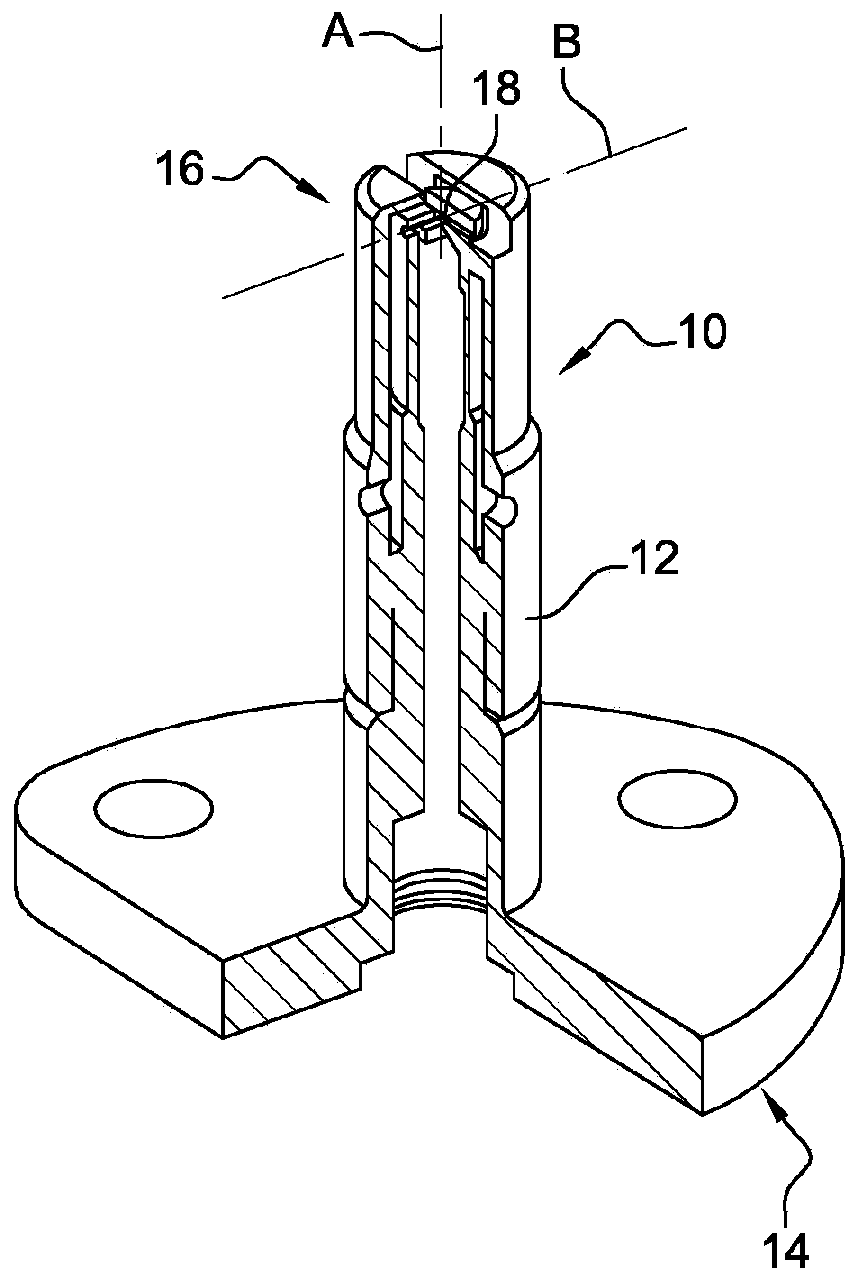

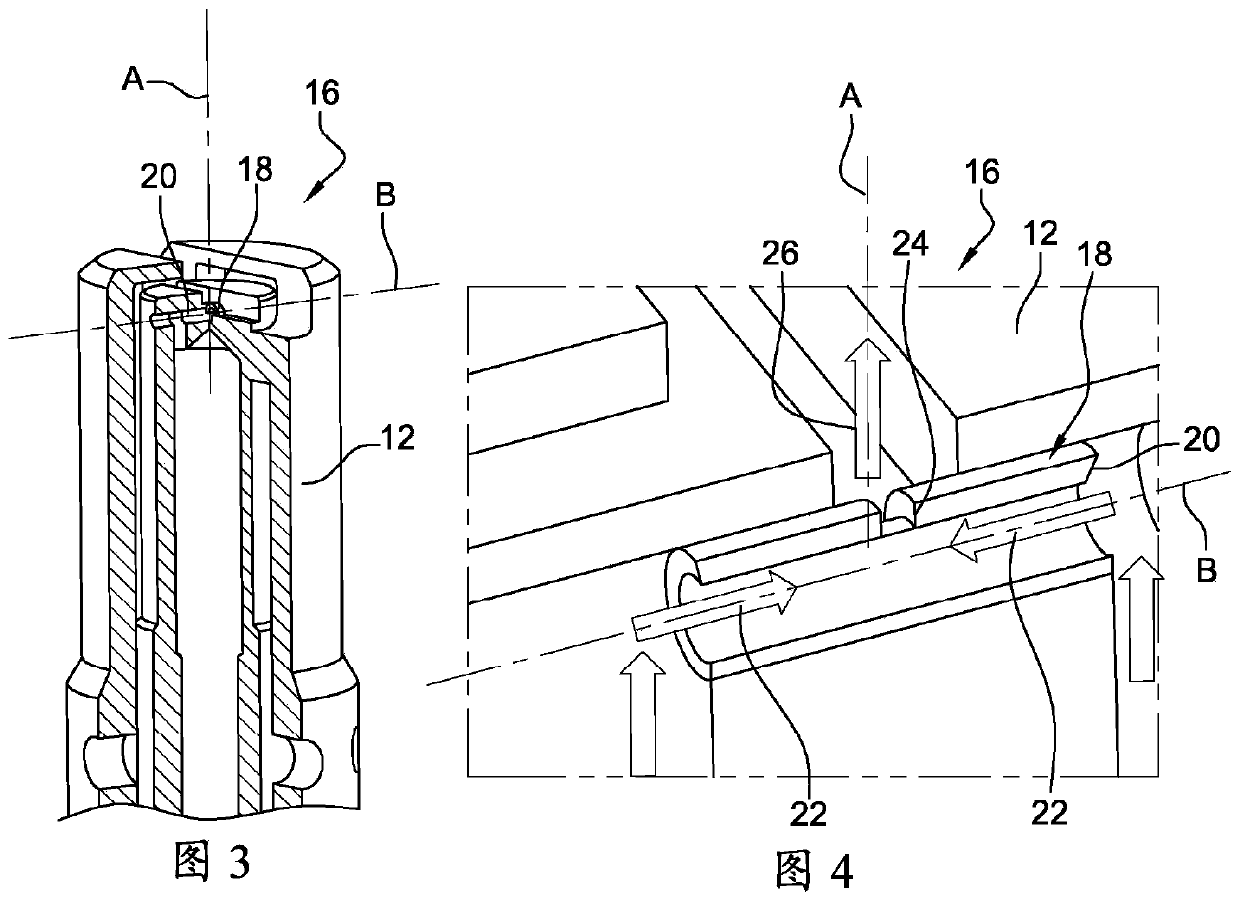

[0032] Figure 1 to Figure 4 What has been described above can of course be used to better understand the invention.

[0033] Figure 5 An environment in which flat jet fuel injector 110 may be used is shown. This is the combustion module of a turbine engine of an aircraft, such as a helicopter, which module includes a combustion chamber 130 .

[0034] A combustion chamber 130 is located within a casing 132 of the turbine engine and includes walls 134 that internally define a combustion space into which a mixture of air and fuel is injected and combusted.

[0035] Fuel is injected into chamber 130 through one or more injectors 110 , here affixed to housing 132 and passing through orifices 136 in wall 134 .

[0036] injector or each injector 110 is figure 1 Types of injectors shown and described above.

[0037] Figure 6a to Figure 24e Several variant embodiments of injector 110 are shown. The injector 110 comprises a body 112 having a generally elongated shape with an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com