Bionic mechanical leg joint driving transmission device

A bionic mechanical leg and drive transmission technology, applied in the field of bionic robots, can solve the problems of inability to meet the requirements of small volume, large load and impact resistance, increased design difficulty of bionic leg mechanism, insufficient output load force, etc., and achieve compact design of leg structure. , good terrain adaptability, the effect of saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be described in detail in conjunction with the summary of the invention and the accompanying drawings.

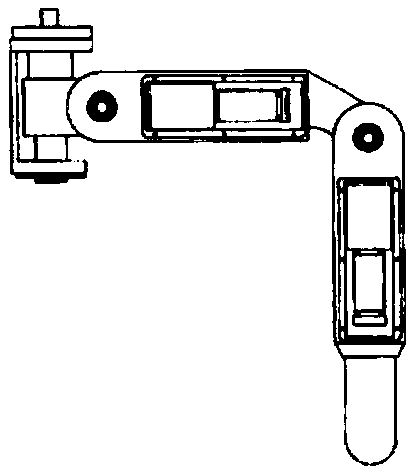

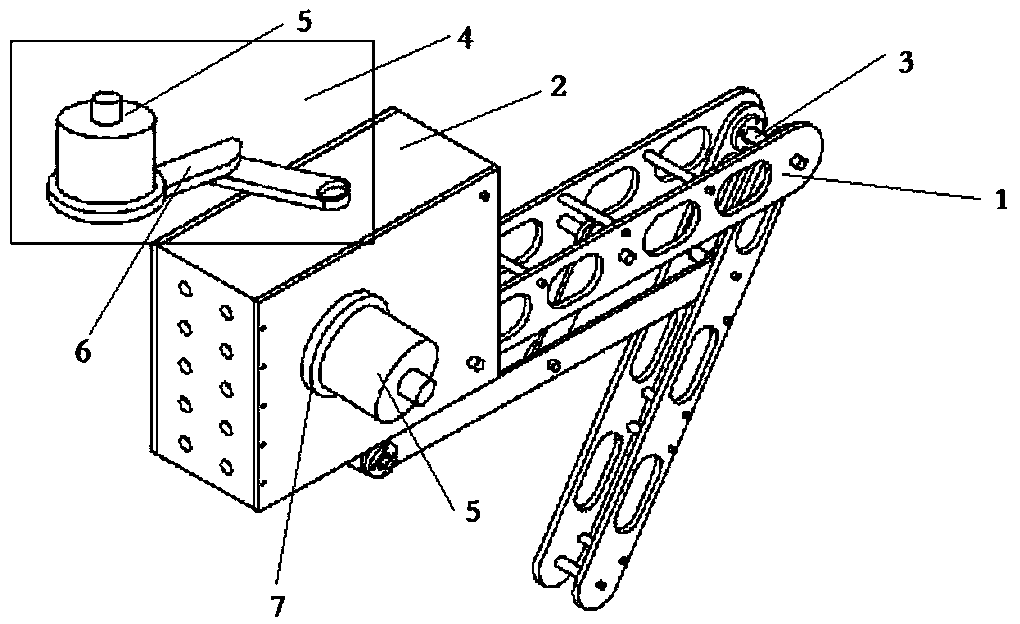

[0031] Such as figure 2 As shown, each bionic leg mechanism 1 has three bionic leg joints 3 of the base joint, the femoral joint and the tibial joint, and each bionic leg joint 3 is equipped with a joint drive transmission device 4 of the present invention to realize the independent operation of each joint. drive and control.

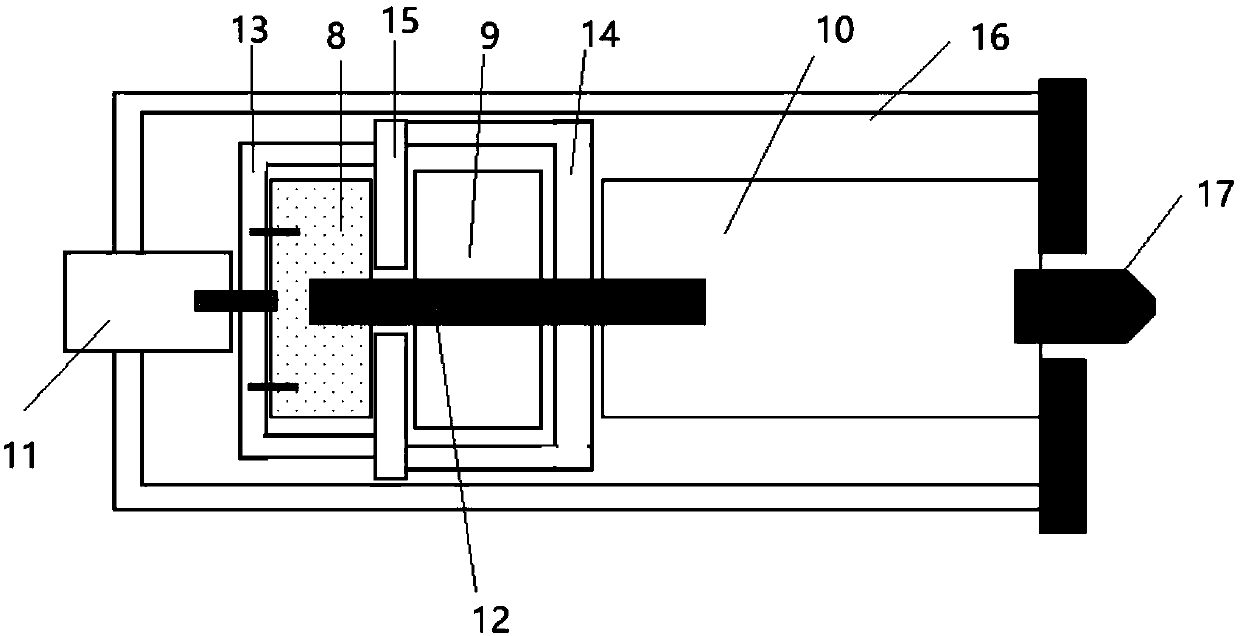

[0032] A bionic mechanical leg joint drive transmission device, including a sequentially connected drive unit assembly 5, a power output shaft 17, a transmission rod 6, and a joint control system; the power output shaft 17 and transmission rod 6 output power from the drive unit assembly passed to the joint control system.

[0033] The transmission rod 6 adopts a multi-link mechanism, and the rotating parts of the multi-link mechanism are connected by bearings.

[0034] Such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com