Heavy-duty lifting translational rotary system device

A technology of translation, rotation, and system device, which is applied in the direction of building types, buildings where cars are parked, buildings, etc., can solve the problems of space limitations in the installation and use of garages, achieve the ability to park vehicles, solve the separation of people and vehicles, and shorten the use of space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

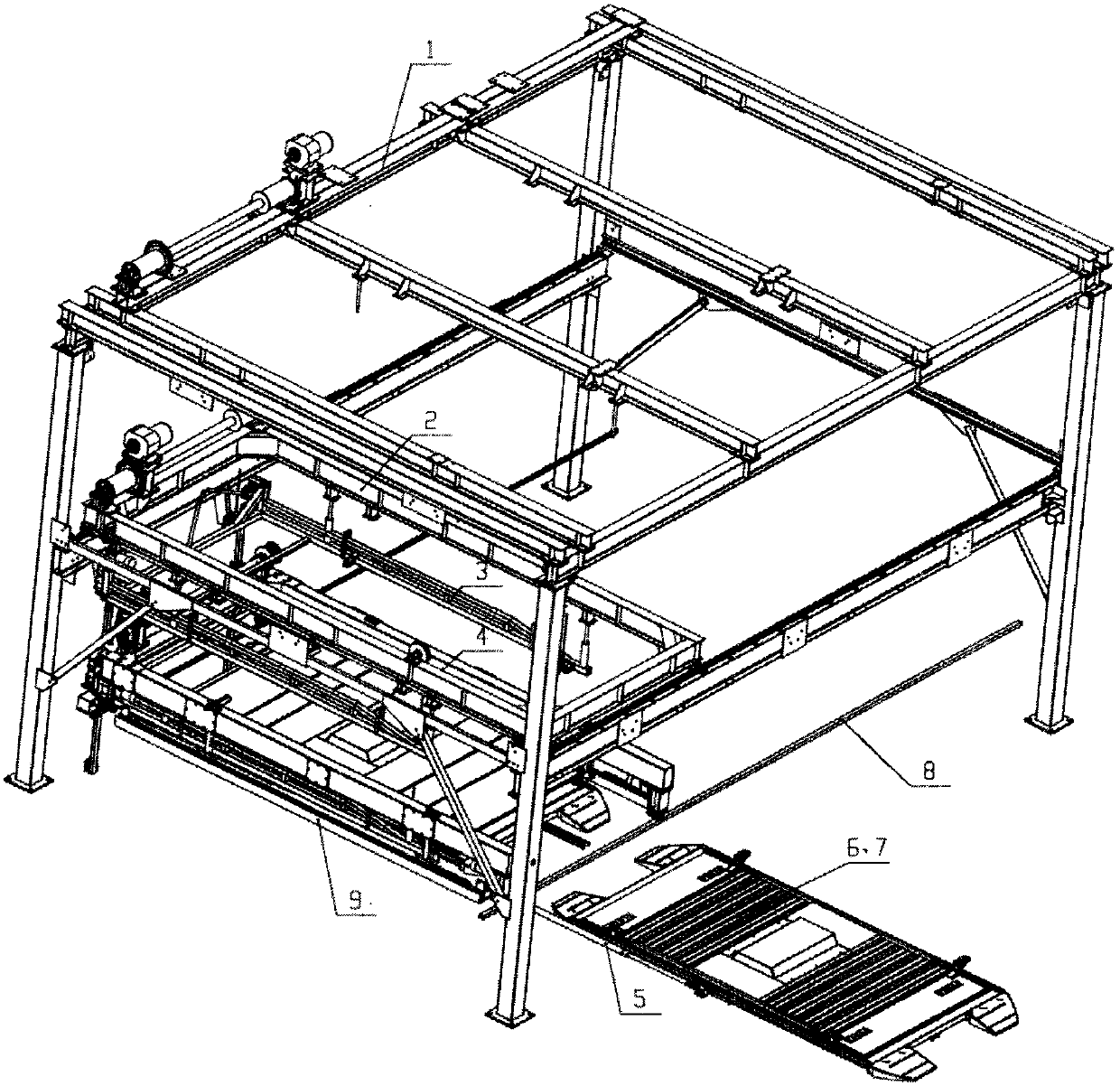

[0036] see figure 1 , schematically shows a preferred embodiment of the heavy lifting, translation and rotation system device provided according to the present invention. As shown in the figure, the heavy lifting, translation and rotation system device mainly includes a skeleton system 1, a frame translation system 2, and a U-shaped hanging frame system. 3. U-shaped translation system 4, power slide bar system 5, load-bearing plate system 6, ground load-bearing carrying system 7, ground rail system 8 and ground power supply system 9.

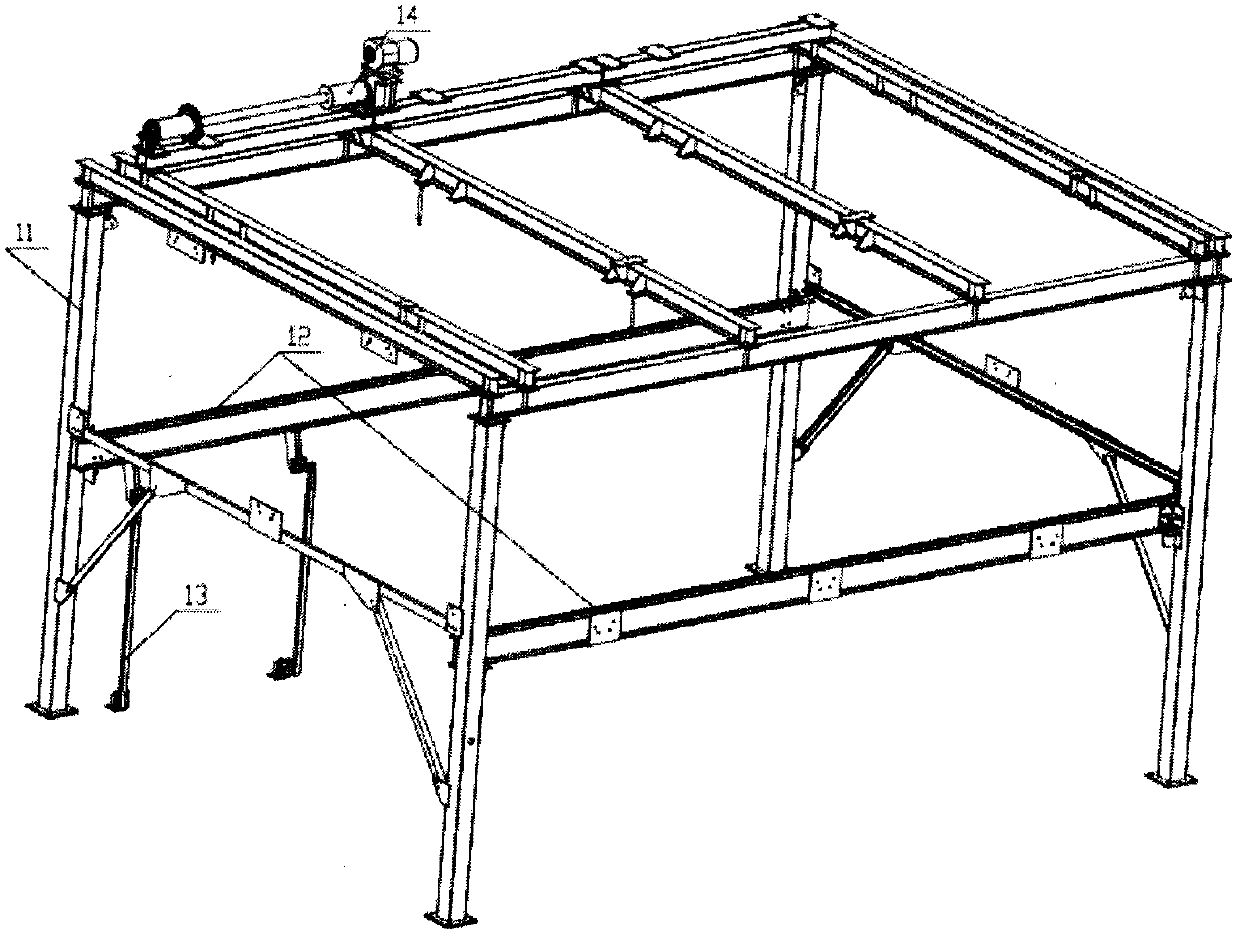

[0037] see figure 2 , the frame system 1 mainly includes a frame steel structure system 11 , a horizontal rail system 12 , a guide plate system 13 and a drive system 14 .

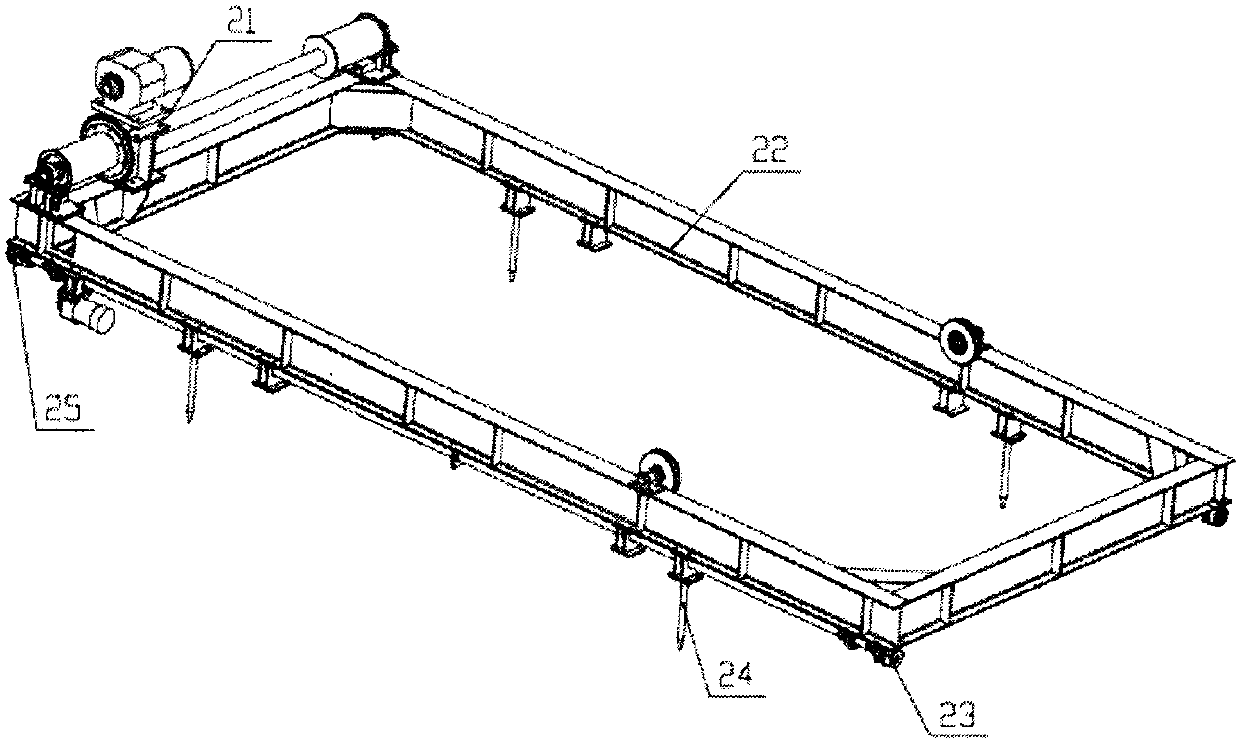

[0038] see image 3 The frame translation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com